LASERDYNE® 795

LASERDYNE®

LASERDYNE's laser drilling technology is a sophisticated and precise process that leverages advanced laser systems for high-precision hole drilling applications. Utilizing flexible laser sources, such as fiber lasers, the LASERDYNE system delivers intense, focused beams with exceptional control over parameters like pulse duration, frequency, and power. This level of precision allows for the creation of micro-sized holes in a variety of materials, including metals, ceramics, and composites. The drilling process is guided by CNC systems, ensuring accuracy down to the micron level.

LASERDYNE's proprietary beam delivery and focusing optics play a crucial role in maintaining a small spot size, resulting in minimal heat-affected zones and precise hole geometries. The system is also equipped with advanced vision systems for real-time monitoring and correction, ensuring consistent and high-quality hole drilling across large production runs.

This technology finds applications in industries such as aerospace and medical devices, where intricate hole patterns and precise dimensions are critical for component functionality and reliability.

Avoiding Back-wall Damage in Trepanning

Deep Hole Drilling With High Power QCW Fiber Laser

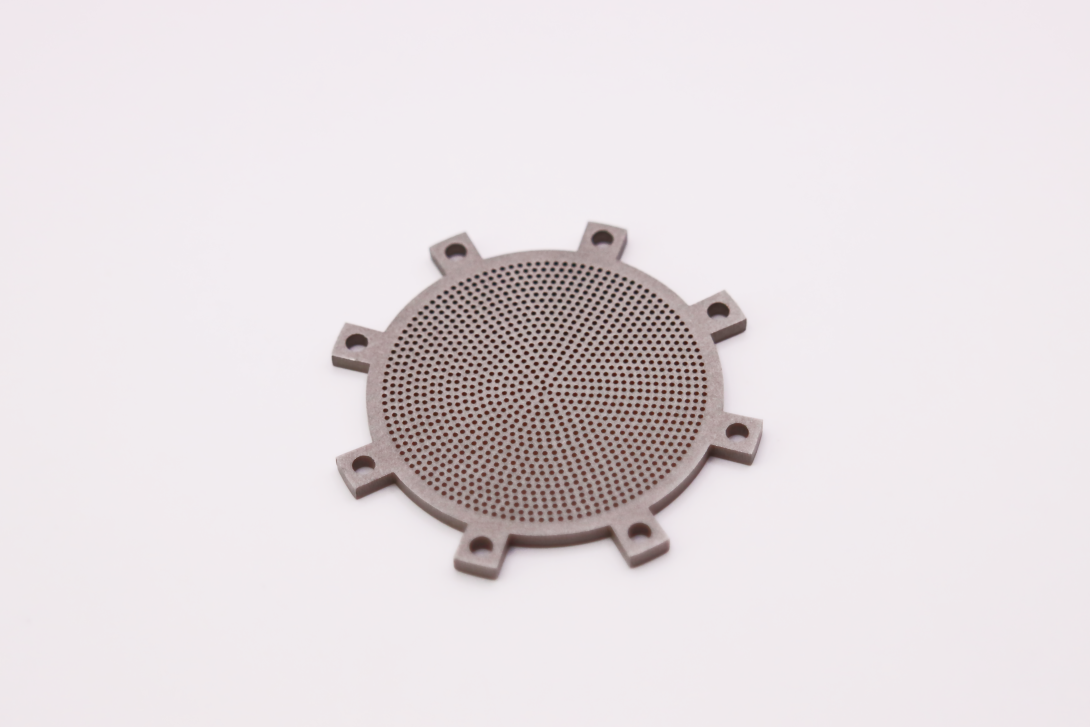

SmartPierce™ Enables Production of Part With Thousands of 0.2 mm Diameter Holes

Stainless Steel Filter Now Laser Drilled Using SmartPierce™

Laser Texturing Metal Surfaces Using Laser Drilling Technology

Laser Drilling and Cutting Composite Materials

Laser Drilling Process Yields Fewer Cracks in Hastelloy X – Part 1

Percussion Laser Drilling of Hastelloy X Nickel Based Superalloy

Minimizing Base Metal Cracking in Nickel-Based Alloys – Part 1

Minimizing Base Metal Cracking in Nickel-Based Alloys – Part 2

Using the Process Calculator to Develop Laser Drilling Processes

LASERDYNE®

LASERDYNE®

STORIES OF EVOLUTION

Lasercraft USA Knows 5-Axis Laser Cutting Backed By 30 Years Experience And The Latest Technology -- Success Grows Using A Newly Acquired LASERDYNE® 430 With BeamDirector®

Expertise in integration

Customer-focused approach

High-speed flexible solutions

An integrated and pragmatic committment.

We operate all over the world: find the Prima Power office closest to you and contact us.

© PRIMA INDUSTRIE S.p.A., single-member company | Via Torino-Pianezza, 36 - 10093 COLLEGNO (TO) ITALIA | Share Capital €26.208.185 | VAT 03736080015 - C.C.I.A.A. Torino 582421 | Reg. Impr. Torino n. 03736080015