Laser Next Core 2131

3D LASER CUTTING MACHINES

Versatility meets cost-efficiency in 3d laser processing

MINIMUM COST-PER-PART

Up to -25% lower than market, thanks to optimized fixed and running costs, by reduced labour intervention, minimal maintenance effort, limited gas and electric consumptions.

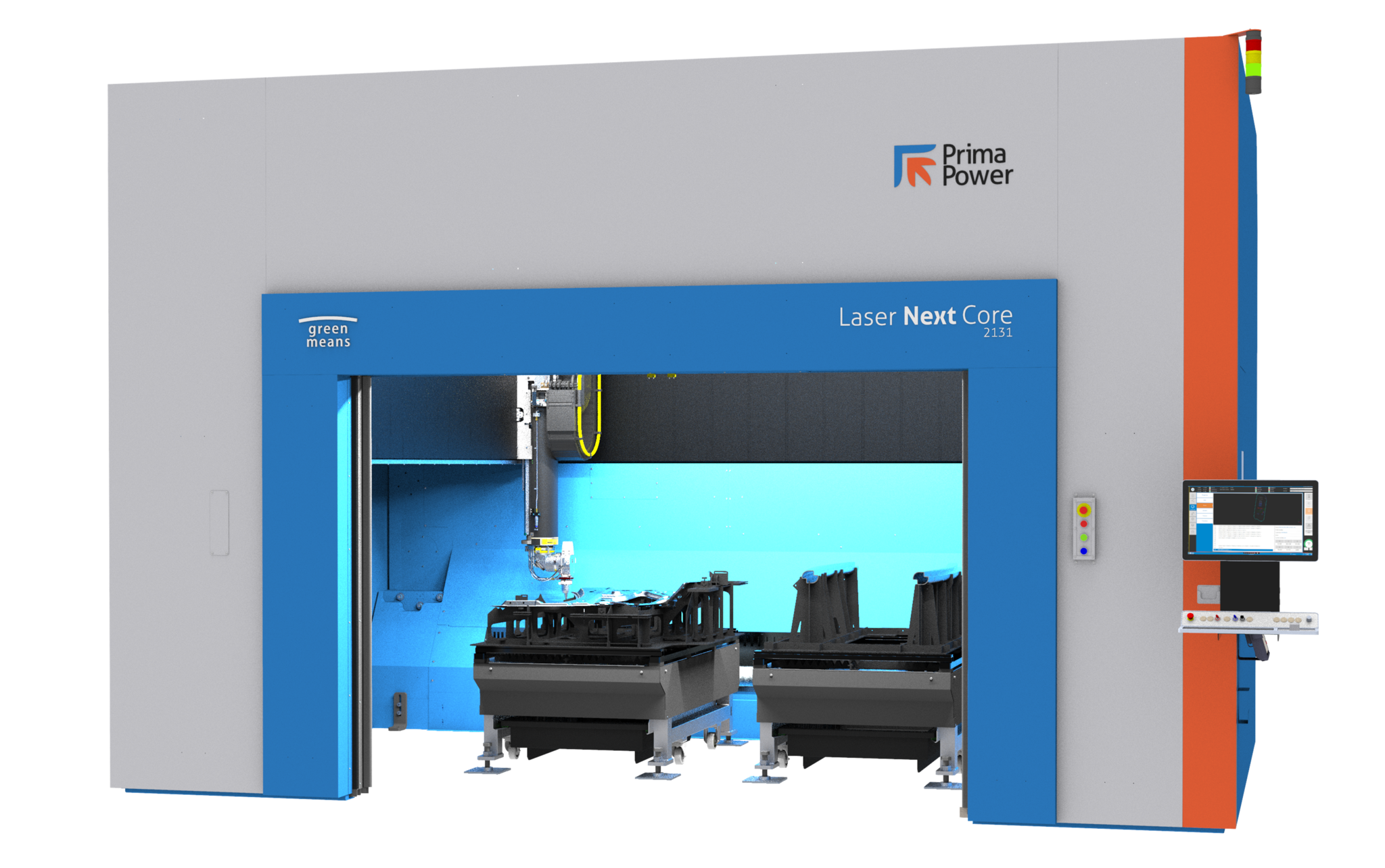

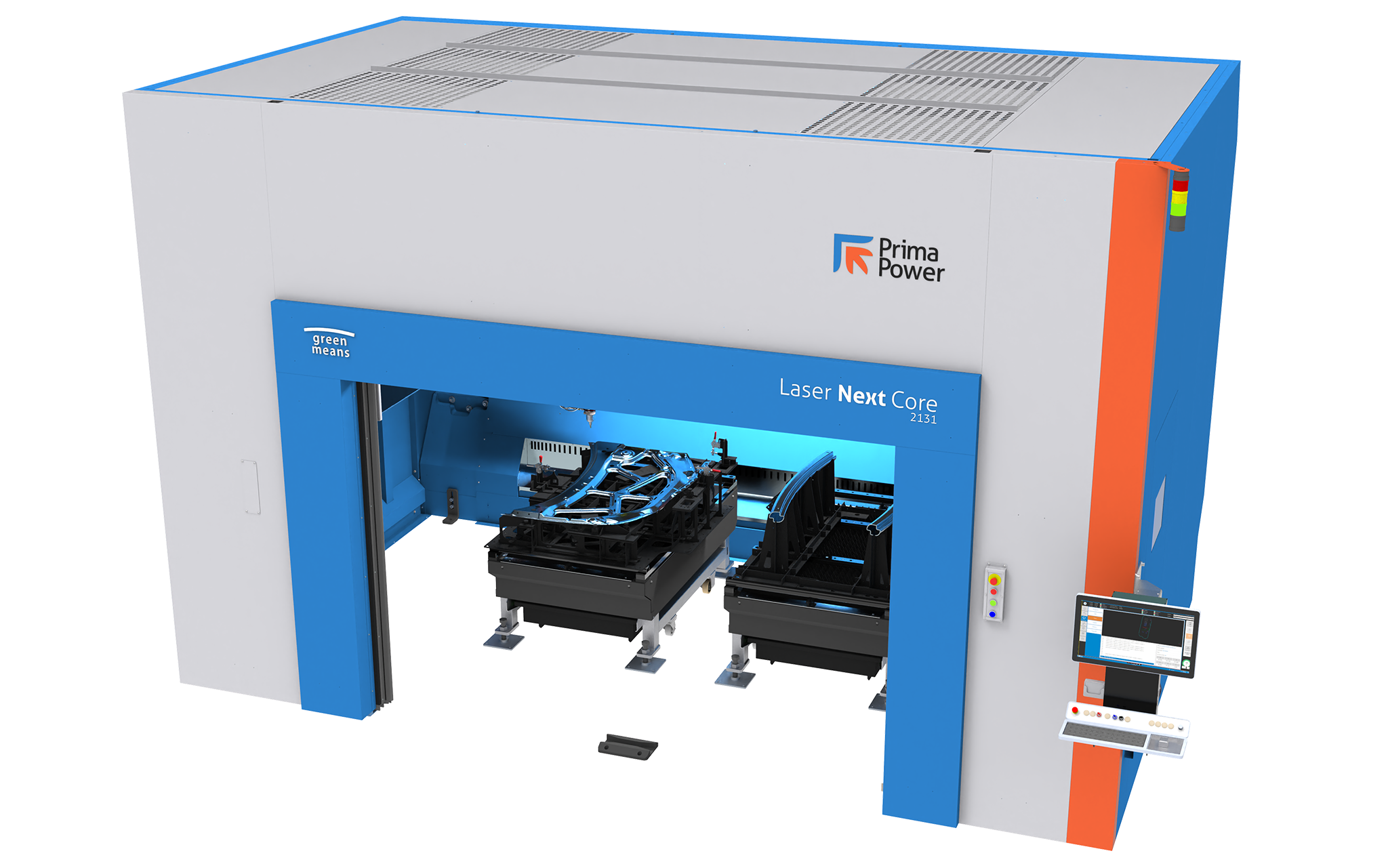

VERSATILE AND COMPACT

Outstanding versatility with +58% larger working volume in its class and a footprint reduced by -25% for maximum floor space efficiency.

QUICK SETUP AND PROGRAMMING

Simplified machine use, thanks to one-click programming, intuitive HMI with graphical teach panel and automatic head-offset compensation.

WIDE TECHNOLOGY RANGE

Wide technology range, from 2D and 3D laser cutting of stainless steel, aluminum and titanium. Optional welding head is available for lap and butt joint welding.

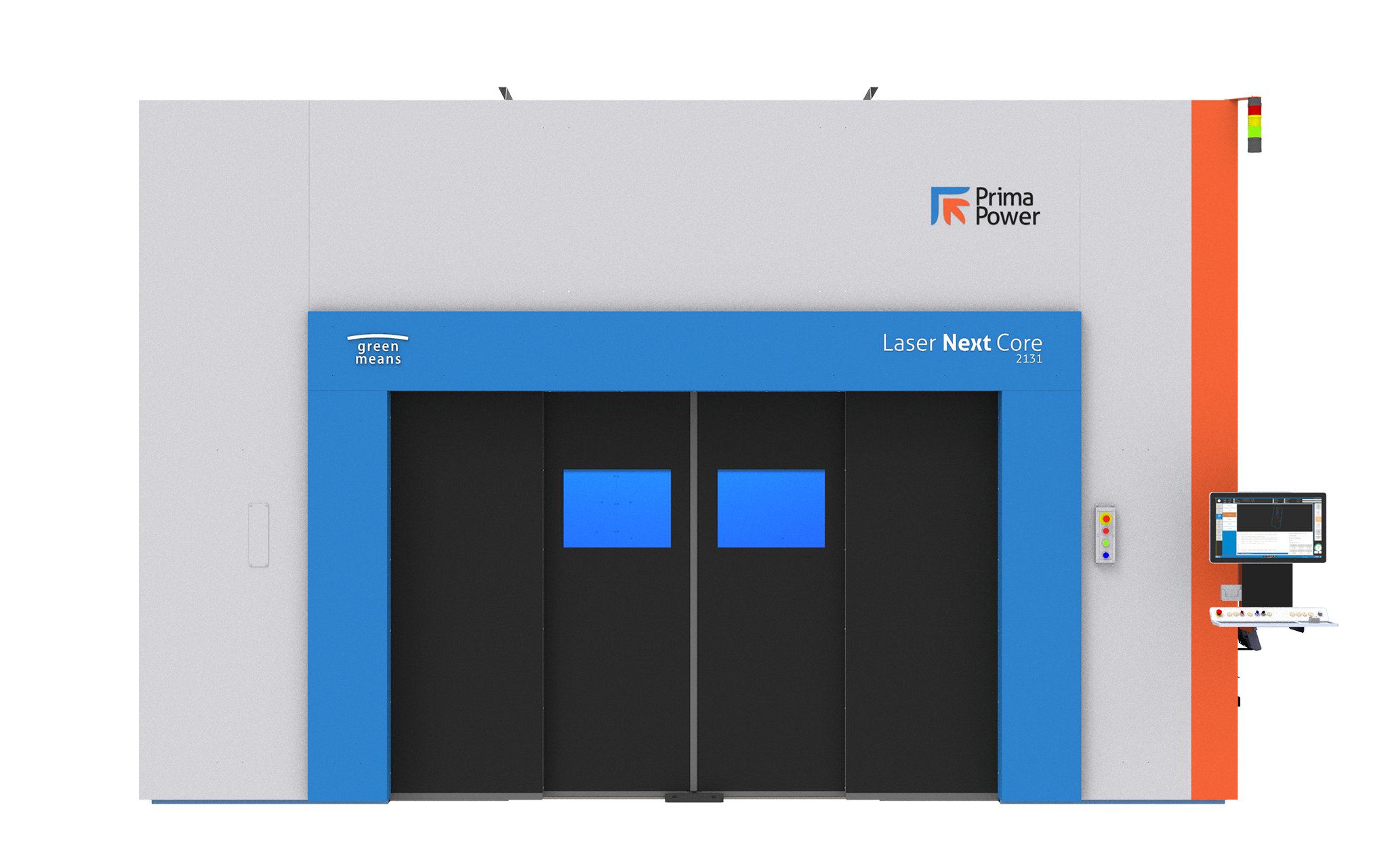

Laser Next Core 2131 brings the performance and reliability of Prima Power’s Laser Next technology into a compact and cost-effective solution. Designed for job shops and manufacturers working with small to medium batch sizes, it offers high application versatility and fast setup capabilities.

The machine supports both 2D and 3D laser cutting, with optional welding features to expand its application range. Its modular architecture ensures precision and low maintenance, while the advanced software ecosystem enables fast programming and easy operation. With a focus on flexibility, Laser Next Core 2131 is ideal for high-mix production environments requiring adaptability and efficiency.

Laser Next Core 2131 brings the proven DNA of Prima Power’s Laser Next technology into a compact, cost-effective solution tailored for job shops and flexible production environments.

Designed to handle a wide range of part sizes and geometries, it offers outstanding performance in both 2D and 3D cutting, as well as complementary welding applications.

Laser Next Core 2131 ensures the minimum cost-per-part, thanks to optimized fixed and running costs, making it a profitable choice for any batch sizes in dynamic manufacturing environments.

• Maintenance-free linear drives and direct motors for high dynamics and reliability

• Dual-position height-adjustable tables for ergonomic and flexible part handling

• Integrated Prima Power HMI and graphical teach panel

• Automatic head-offset compensation by local head axis (C axis)

• One-click programming by CAM

• Optional welding head to expand application range to lap and butt joints

• Minimum gas consumption thanks to safe cutting nozzle saving up to -30% Nitrogen

Axis strokes

X=3,160 mm Y=2,100 mm Z=750 mm

Head axis strokes

A 360° B ±135° C ±12 mm

Speed

X, Y, Z 90 m/min (trajectory 155,9 m/min)

A, B 540°/1.5 rev.

Accuracy*

Pa, Ps 0.03 mm (VDI 3441)

Fiber laser source

3,000 W – 4,000 W

*The accuracy of the piece depends on its type, size and pre-treatment, and the conditions of application.

Take a look at the other products and choose the best solution

Laser Next 1530-2130

3D LASER CUTTING MACHINES

El sistema láser 3D para la producción del sector de la automación

Laser Next 2141

MÁQUINAS DE CORTE POR LÁSER DE 3D

La solución flexible con un espacio de trabajo grande y eficacia de mejor en su clase

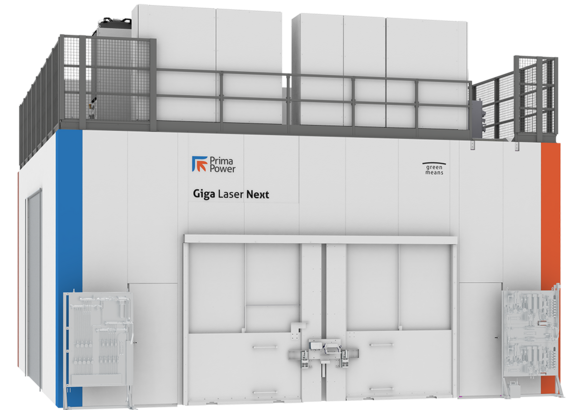

Giga Laser Next

MÁQUINAS DE CORTE LÁSER 3D