折弯中心

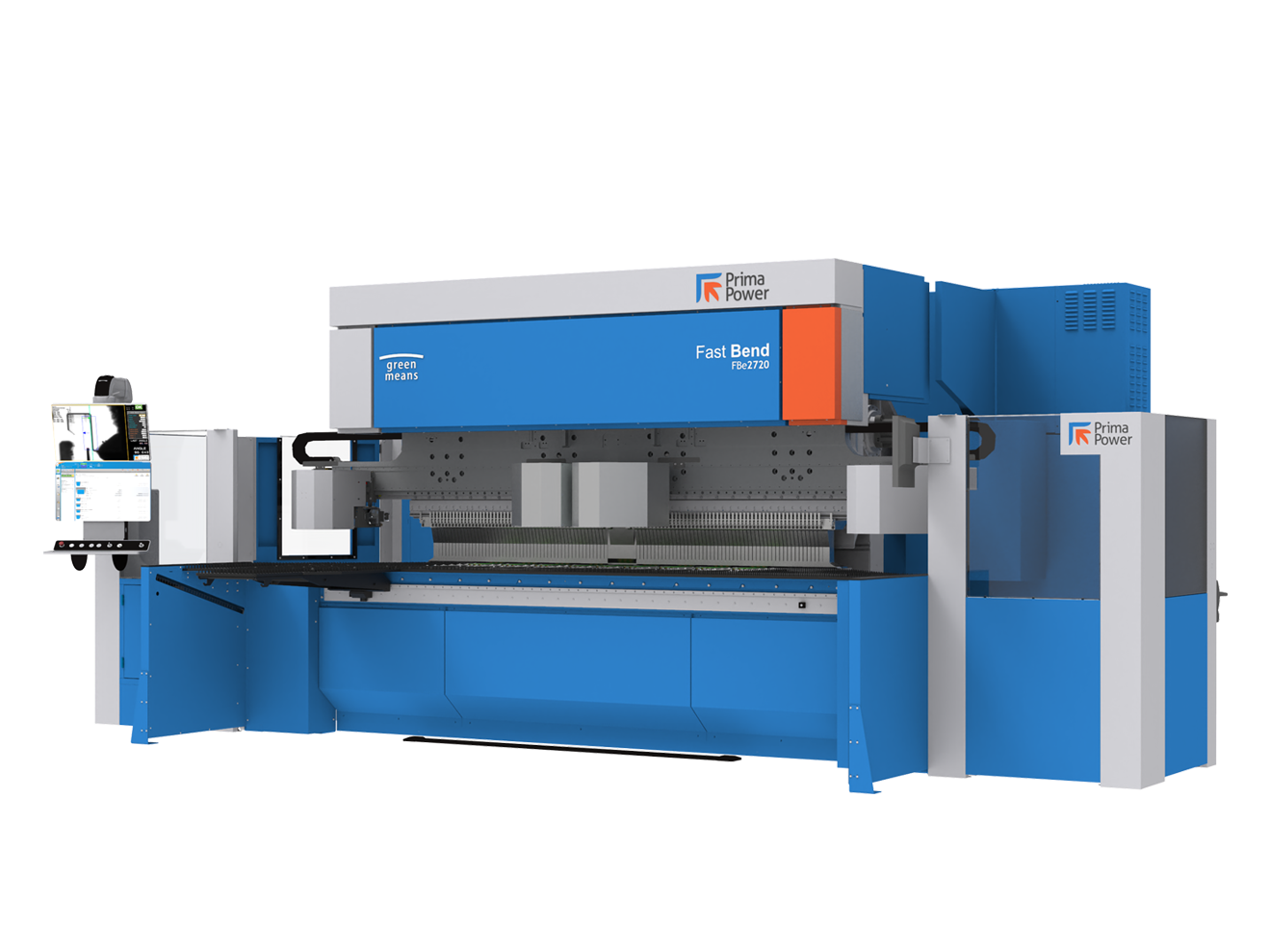

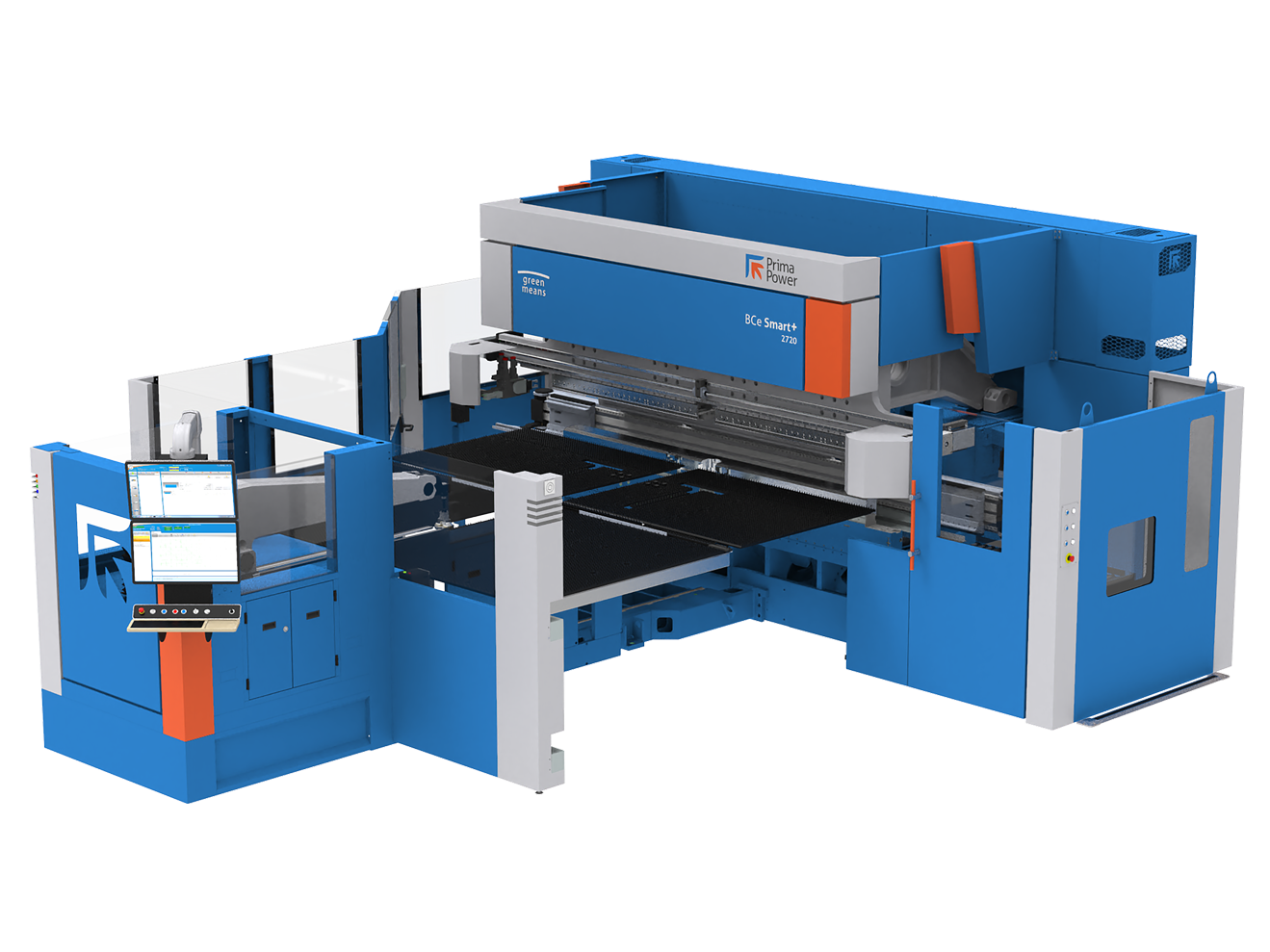

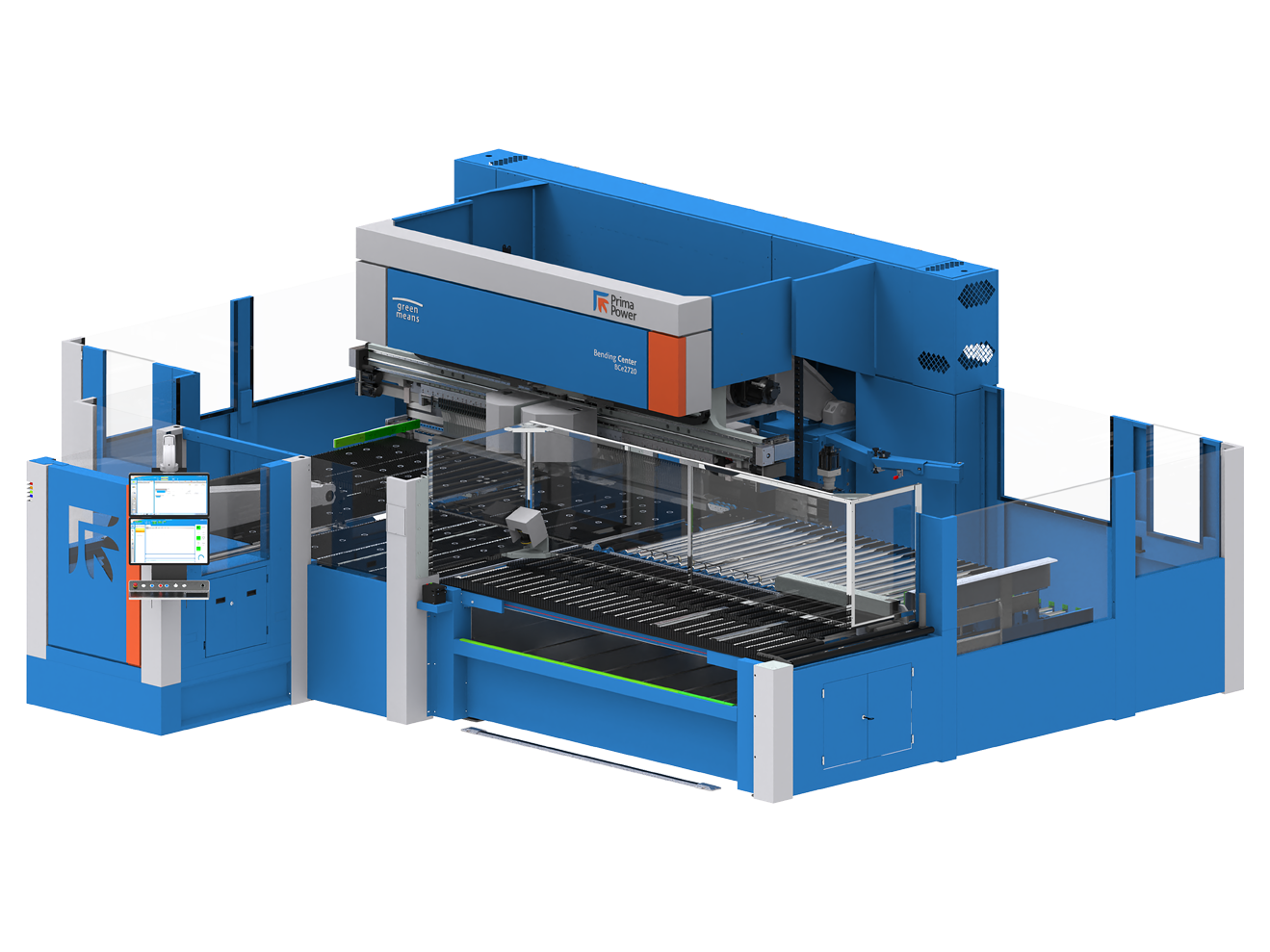

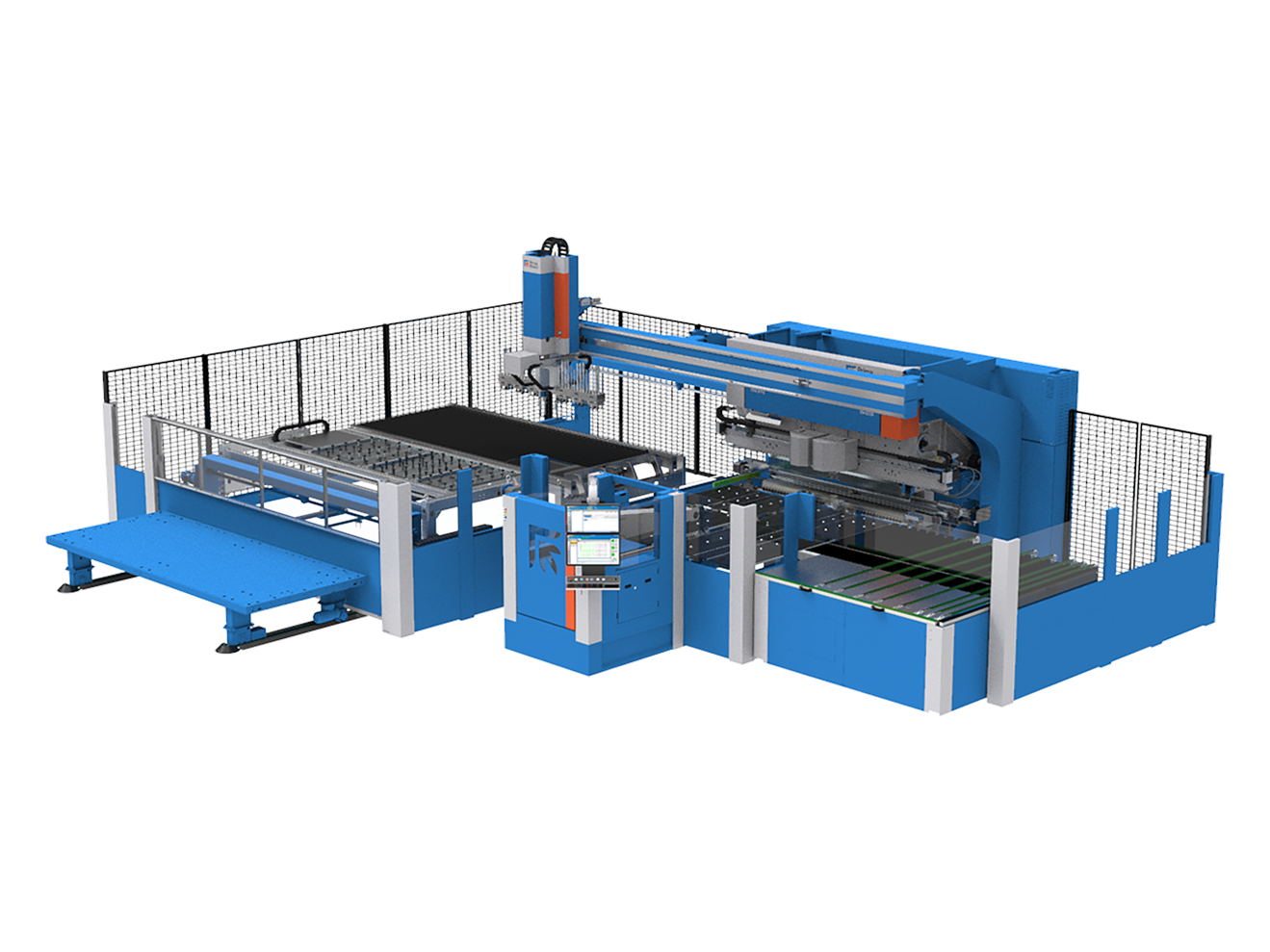

借助我们全电伺服解决方案的自动化特性来提升您的效率

- 借助我们的全电伺服技术,单个零件的成本最低可做到比市场平均水平低10% (1)

- 我们提供多种配置和尺寸,即使是面对小批量生产和复杂的折弯形状,也能展现出卓越的灵活性。

- DABA (3) 技术显著提升了高精度和可重复性,使其能够进行一流的加工,且材料厚度最高可达4 mm (2)

(1)基于内部数据分析,以总拥有成本为计算依据(2) 低碳钢最高3.2mm, 不锈钢最高2.5mm, 铝最高4mm (参考EBe).(3) DABA: 折弯角度动态调整

成功案例

了解普玛宝折弯中心技术如何帮助公司取得成功

Biohort GmbH

Biohort | 高级钣金加工

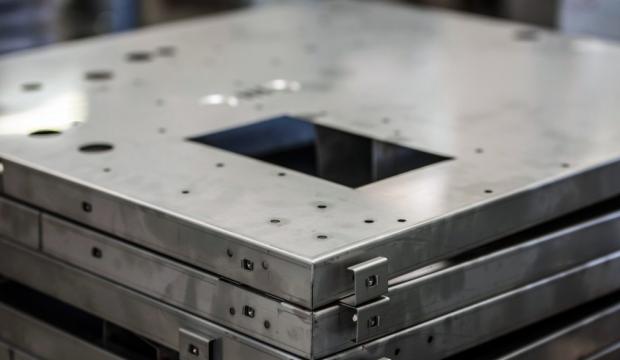

在上奥地利州黑尔措格斯多夫新建的Biohort制造工厂只一年便竣工。凭借领先的行业标准和优化的过程周期,储存空间解决方案的专家在诺伊费尔登总部新建了2号车间,为支持进一步增长创造了新的资源。

Lasertech Metal Works

普玛宝EBe Express折弯中心提高了佐治亚州作业车间的生产率和生产质量

当Randy Williams开设第一家作业车间时,他已经是一名富有经验的装配工。“我是随着金属加工业一起成长的,”Williams介绍道,“我的父亲是一名航空工程师。在我10岁时,他兼职制造蹦床,我在地下室帮他制造零件。后来,他的业务范围扩大到制造摩天轮和其他便携式游乐设施,但作为一家小公司,最后因为难以负担责任保险而无法维持经营。”

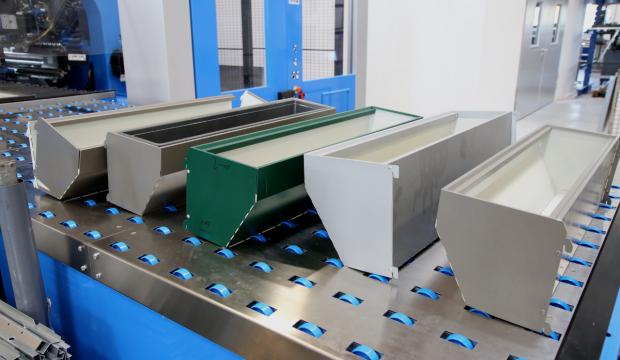

FlexMet Inc.

Why a metal fabricator jumped into panel bending

FlexMet continues to change its manufacturing focus, now with a new bending tool. A new product focus and a desire to automate bending are just two of the reasons that FlexMet, Franklin, Tenn., operates a panel bending machine instead of relying on more press brakes for its bending needs.