服务协议和保修延期

如今,预防性维护已远远不只是更换机油和润滑脂那么简单。

普玛宝维护任务是特定于设备的,由大量的测量、调试和软件控制任务组成,且只能由接受过相应培训的OEM方人员执行。

我们的理念是通过监测设备的状况为您节省时间和金钱。我们将根据从众多现有在用设备上收集的信息更新维护任务列表。

我们的所有服务协议都允许客户依赖于我们根据最新的信息执行的维护。这将让他们获得最经济的总体拥有成本。

服务协议是在设备的生命周期内确保设备维护的首选方式。这是确保遵守设备维护计划并将计划外停产风险降至最低的最佳方法。

保护您的设备,让您安枕无忧

- 预防性维护可减少意外故障/停机

- 计划内停机的成本将低于计划外停机

- 设备将保持尽可能高的生产质量 - 具有竞争力的维护成本

- 设备能够满负荷连续工作,并保持最佳工艺效率

- 安全的工作环境

- 可尽可能减少对环境的影响

普玛宝服务协议的优势

- 享受劳务费用折扣

- 免费获得技术支持

- 优先获得服务干预

- 所有备件均享受折扣价

- 使用最新的维护操作列表

- OEM预防性维护计划

- 在办公时间免费获得技术支持

- 专业的校准工具和方法

- 6个月保修的原装备件

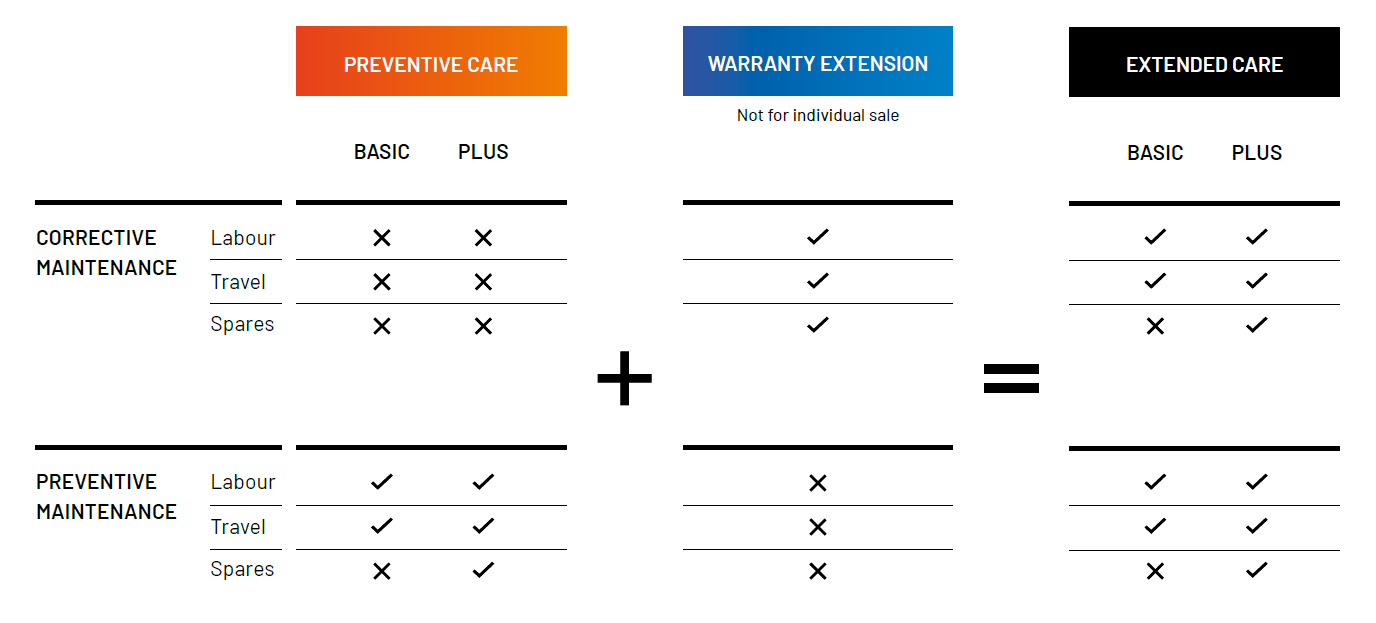

为您的业务选择合适的服务协议

即使是选择基础级别的预防性协议,客户也可以确保遵守设备的维护计划,并降低计划外停产的风险。

扩展维护协议可最大程度的限制客户服务和备件的成本,适合那些想要将成本编入预算的用户。

普玛宝服务协议分为三个系列:

Our services

成功案例

了解选择合适的普玛宝设备对于公司取得成功有何帮助

Fhiaba | 普玛宝技术,共铸奢华制冷臻境

专注于食品与名酒保存的超高端家用电器制造商Fhiaba,通过引进创新的普玛宝技术,对其生产线进行了升级。先进的钣金加工系统集成优化了生产流程,在实现生产最大灵活性的同时,确保了产品始终如一的卓越品质。

IMPEA | 技术创新的典范

IMPEA依托最先进的制造技术,并与普玛宝(Prima Power)等知名伙伴在二维/三维激光切割领域紧密合作,致力于保障其钣金加工在质量、效率与灵活性方面均达到卓越标准。

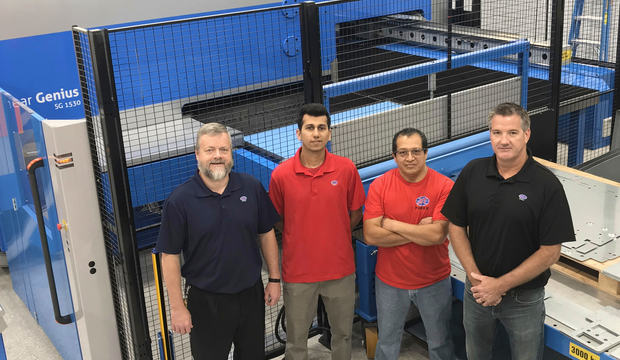

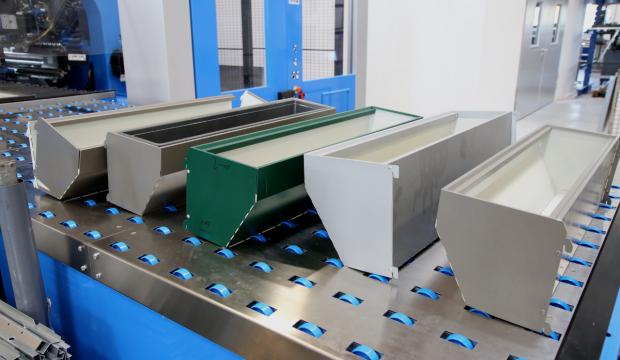

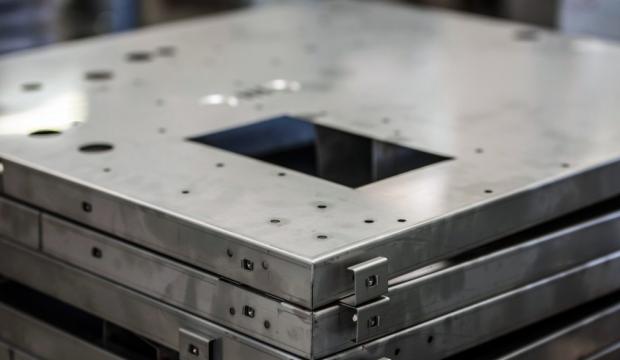

New beginnings - Supporting ARC Industries’ new launch

Machine manufacturers are rarely confronted with the number of requirements Arc Industries presented – yet great energy and passion for a job well done allowed a new business relationship to flourish.

Five Seasons:自动化折弯为生产力扫清障碍

自动化折弯技术通过减少设置时间和劳动力,显著改变了 Five Seasons 的生产模式,实现了高精度和更快的交付速度。

Proslat:改变北美制造业

Proslat通过集成先进的自动化技术,实现了生产流程的高效平衡,并有力推动了零售业务的拓展。作为一家加拿大企业,其对普玛宝技术的前瞻性投资不仅显著提升了生产效率,更为北美制造业的回流创造了有利条件。

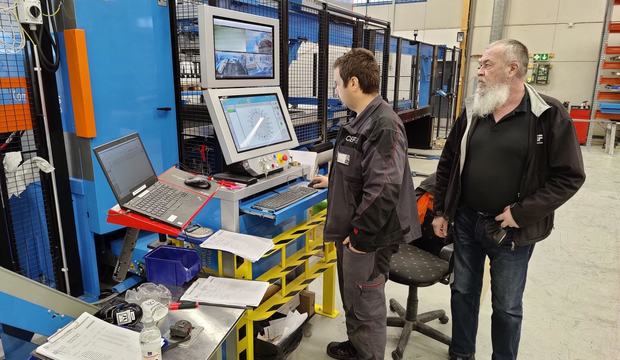

专注于自动化 爱沙尼亚分包商Alise Technic OÜ

位于爱沙尼亚帕尔努的分包企业Alise Technic OÜ,其创立可追溯至25年前的2000年。彼时,公司的发展征程开启于与一家德国企业达成合作协议,着手为其生产制造车库门的金属零部件。

A path towards automation and sustainability

How Woojin Plaimm improved productivity and workforce health with Prima Power’s technologies.

成立50周年的Piristeel公司凭借投资推动强劲增长

Piristeel 是芬兰领先的雨水系统和屋顶安全产品制造商,其品牌名称为 Pisko。2024 年,公司将迎来 50 周年庆典。Piristeel 致力于打造更安全的建筑环境,其创新和高品质的产品得到了市场的认可!

SPE引领技术革新,引进普玛宝Bce 2720折弯中心

虽然制造过程往往不被视为充满华丽色彩的活动,但普玛宝BCe 2720折弯中心的操作却是一场视觉盛宴。目睹这台半自动折弯中心执行高精度折弯的过程,就如同欣赏一场流动的工艺诗篇。

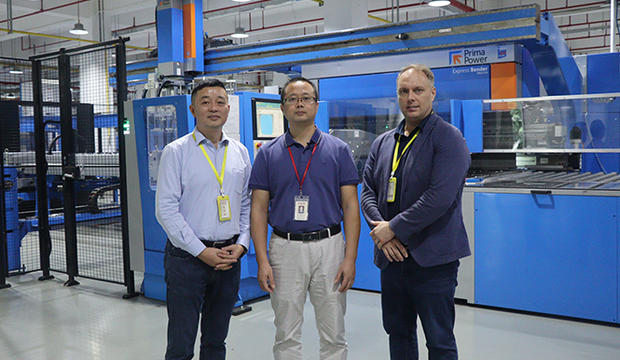

Zhilai - Punching forward: leading manufacturing innovation

Chinese industry leader partners with prima power to forge a new future in intelligent custody and delivery.

Chasestead - Cutting-edge investments to make production more efficient

Chasestead's latest acquisition in Fiber laser technology hits the mark

Zhixin - Revving up growth in the automotive industry

Zhixin’s expansion boost with 35 Prima Power’s laser-cutting machines.

Cadrex - Combining technologies to evolve capabilities

American company leverages Prima Power for streamlined process integration.

Dringenberg - Boosting production capacity through automation and integration

The leading German manufacturer optimized its processes and achieved higher flexibility thanks to Prima Power's fully automated and integrated PSBB line.

长期的合作伙伴 - Lojer Oy

Lojer Oy是北欧地区最大的医院和医疗家具制造商。公司在芬兰的萨斯塔马拉、霍洛拉和肯佩莱地区分别设有三家工厂,其中萨斯塔马拉工厂是中心工厂。

Glenn Metalcraft, 凭借三维光纤激光大展拳脚:完美适配重型金属旋压组件

从业务增长的角度来看,规模的重要性不言而喻,同样,从促进成功所使用的方法和设备的角度来看,尤其是当零件尺寸(规格)因新应用而扩大时,规模也显得至关重要。随着业务的持续发展,必须更加依赖于与关键客户和供应商建立战略伙伴关系,采纳新技术和工艺,承担包括收购在内的预期风险,并不断提高运营效率。

C & I Enclosures - 冲剪组合将生产率推至新高

C & I Enclosures,是一家电气外壳制造商,他们一直在寻找一种全新的、最先进的设备,这种设备能够将零件从初始生产阶段转变为最终生产阶段,而无需进行

Pipemodul Oy, 通过技术强化商业价值

Pipemodul Oy是一家芬兰家族企业,生产预制管道和电缆箱。他们选择使用普玛宝的伺服电动折弯机,以加强对负责任制造实践的承诺。

Metaltecnica带给全球餐饮业的意式激情

Metaltecnica是一家设备制造的公司,旨在最大限度地提高效率和降低能源消耗的同时提升产品性能,以在全球范围内实现厨房的最高卫生标准。该公司提供广泛的解决方案,分为六个产品类别,并在其制造过程中使用了许多高性能的普玛宝设备。

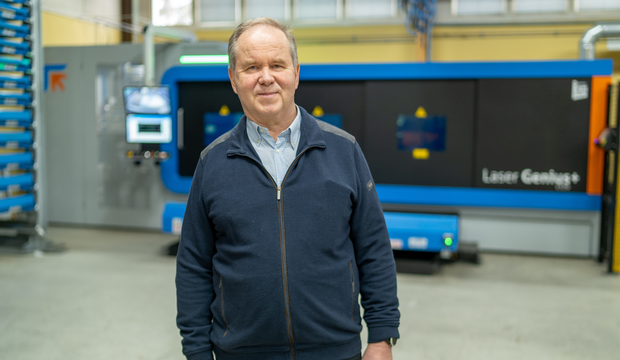

Bierkühl Oy及Laser Genius+激光切割机的故事

Bierkühl Oy是一家位于米凯利的饮料设备制造商,以其创新的芬兰专业技术和高品质而闻名。其客户包括饮料行业的领先运营商和酿酒厂。该公司的自有品牌Bos® Cleantec还是清洁通风管道和无尘翻新工作设备的合同制造商。

合作、能力及强大的机械基础- Mittametalli Oy

Mittametalli Oy成立于2012年,但其起源可以追溯到四十多年前,当时该公司的主要所有者兼董事Jari Kolehmainen在他父亲的公司Lankapaja工作。

DAV,非凡创意,源于传统

在"工业4.0"的定义出现之前,DAV金属制造公司就一直以投资新技术为导向。该公司位于意大利米兰罗镇(Rho),决定专注于高度自动化的普玛宝Combi Genius 1530冲激光复合机,以提高生产效率并扩大可以在设备上直接进行的加工操作范围。

Raytec, always with an eye toward automation

Raytec LLC, a fourth-generation Pennsylvania family business, has experienced rapid expansion by investing in Prima Power equipment and turning their operation from completely manual to fully automated.

Laitila零部件及涂层公司投资购买了一台复合机

2020年4月底,Laitila涂层有限公司的总经理Kai Salo和生产总监Petri Kallio访问了普玛宝位于芬兰塞伊奈约基(Seinäjoki)的工厂。此次访问的目的有两个方面,首先是其投资的普玛宝新一代Combi Sharp 1225冲激光复合机以及与之相连的Compact Express自动化装置的交付,另外他们还进行了与客户特定需求相关的测试运行。

Uudenmaan Ohutlevy,对成长和发展的渴望促成了投资

位于芬兰凯拉瓦的Uudenmaan Ohutlevy Oy公司为来自各行各业的机械和设备制造商提供所需的钣金零部件和组件。绝大部分的生产是各种不同配置的单个组件,当然也有焊接组件。大部分出货是经过切割、边缘加工、攻丝和其他不同紧固件加工的产品。

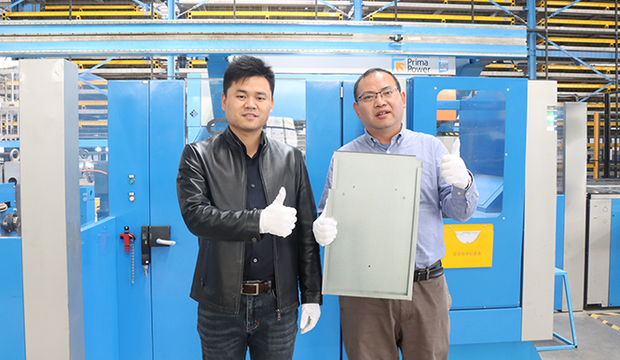

日海智能: 携手普玛宝打造标杆智能工厂

日海智能科技股份有限公司成立于 1994 年,是一家在深圳上市的国家高新技术 企业,也是全球首家人工智能物联网( AIoT ) 创新企业,主营业务为无线通信模组、 通信设备、通信工程服务。日海智能在深圳、上海和西安有研发基地,在美国、法国、巴西和印度等国有分公司, 2022 年的营收是 33.6 亿人民币,是全球领先的信息通讯设备制造商。

Control Express Finland, The new combination machine brought quality and certainty

Established nearly 30 years ago, Control Express Finland Oy, or CEF, started its operations with IT related projects and the import of industrial electronics.

Rappo:老朋友,新技术 -优质客户服务的价值

在普玛宝,我们致力于在相互信任相互尊重的基础上与客户建立长期的业务关系。但这可不是我们自己说的:我们的客户Rappo与我们共事了25年,他也有同样的感受。

De Wave, 高效和高产才是王道

穿梭在世界各地的海洋上,接待人数从几十到几千不等,这就是我们说的游轮、大型游艇和内河船。这些船只所涉及到的船舶家具和配件正是由De Wave集团利用普玛宝的高性能自动化生产线的集成技术制造的。

Clivet, 伺服电动技术助力成长

作为全球最大的热泵和制冷机生产商之一,Clivet选择利用普玛宝的集成伺服电动技术及高度自动化的工业4.0解决方案来对其钣金加工车间进行全面的现代化升级改造。PSBB生产线是该部门的核心,通过冲孔、剪切、缓冲和折弯工作站管理整个生产过程。

JST, 能够始终对客户说“yes”,拥有这样的正确设备是无价的

开关柜是按订单设计产品,订单和订单之间有很多的差异,加工的钣金零件也不尽相同。自动化冲剪复合机促使全新的JST电力开关设备制造厂能够出色地完成小批量生产。

光纤激光切割机Platino Fiber -高科技制造商VTI的选择

激光切割技术的引入加快了位于田纳西州的一家气体泄漏检测技术供应商的生产,允许他们将水射流切割机用于其他作业,这是真空技术股份有限公司(VTI)的全面胜利。

Scott Springfield Mfg, a compact solution for customer success

Scott Springfield Sfg, inc. in Calgary, Canada, is a leading supplier of custom air handling systems, utilizing the latest technologies to provide its customers with a flexible solution to their air handler needs.

Gi.Metal, 为批量生产做好准备

如果说意大利美食是世界上最负盛名的美食之一,那么这肯定要归功于将食谱推广到全世界的厨师,但那些生产厨具的厂家也起着非常重要的作用。例如专业从事披萨店设备制造的Gi. Metal,其在进行切割加工时使用的普玛宝激光。

Rizzato SpA, modular technology and automation to stay one step ahead

Rizzato S.p.A., an Italian leader in subcontracting for the processing of stainless steel and other materials for semi-finished and finished products, is in constant evolution for excellence. At the base of its growth, a strong entrepreneurial spirit and a continuous commitment to always be at the forefront of production technologies and automation. The farsighted choice of a modular automatic storage solution has kept the company one step ahead for over 20 years, adapting to growing production needs.

Stremet Oy and and the future in growth and partnerships

Stremet oy is a finnish sub-contracting company based in Salo, south-western Finland, with over 25 years of solid experience in its field.

Why a metal fabricator jumped into panel bending

FlexMet continues to change its manufacturing focus, now with a new bending tool. A new product focus and a desire to automate bending are just two of the reasons that FlexMet, Franklin, Tenn., operates a panel bending machine instead of relying on more press brakes for its bending needs.

普玛宝PSBB帮助大型发电公司构建柔性制造系统

HIMOINSA总部位于西班牙,拥有8个生产中心、13家全球子公司、1,000名全球员工,与遍布全球的130多家分销商密切合作。母公司Yanmar集团是从事发电设备设计、制造和分销业务的全球顶尖巨头之一。

道路冰雪铲除工作更高效

Giletta(Bucher Municipal集团下属公司,生产和销售除雪机器设备的领先公司)决定安装普玛宝的全新光纤激光切割系统和伺服电动折弯机,从而将钢制构件部门业务重新搬回到公司内部,结束大约三十年的外包历史。

30多年丰富经验及持续增长的生命力

Lasercraft USA 通过采购配备BeamDirector®加工头的LASERDYNE® 430,了解了其基于30年的经验和最新技术支持的五轴激光切割技术,从而获得了成功

凭借普玛宝设备走出困境,创造成功

失去一位为自己提供98%的业务来源的客户后,能在短短几年内重回正轨,有多少车间能做到这一点?这正是Elm Machining在几年前所面临的困境。

普玛宝EBe Express折弯中心提高了佐治亚州作业车间的生产率和生产质量

当Randy Williams开设第一家作业车间时,他已经是一名富有经验的装配工。“我是随着金属加工业一起成长的,”Williams介绍道,“我的父亲是一名航空工程师。在我10岁时,他兼职制造蹦床,我在地下室帮他制造零件。后来,他的业务范围扩大到制造摩天轮和其他便携式游乐设施,但作为一家小公司,最后因为难以负担责任保险而无法维持经营。”

先进激光设备满足工装集团的多样化需求

受益于先进的激光技术,位于美国密歇根州麦迪逊海茨市的Diversified Tooling集团旗下的四家公司成为领先的单一来源供应商,能为汽车、重型卡车、国防、工业设备、发电、铁路和铸造工业提供一站式制造解决方案。

Laser Genius:Midwest Job Shop的明智投资

在过去五年,R & M Manufacturing面临一个令人振奋的挑战。公司由于增长迅速,因此预测未来来自电气、发电、太阳能、空气净化、暖通空调、住宅建筑工业的客户订单将会增加。

Platino光纤激光和料库消除通风设备制造商遇到的阻碍并提高生产率

Soler & Palau (S&P) Ventilation集团是全球顶尖的通风机制造商。公司凭借在业内60多年的丰富经验,供应范围广泛的通风产品。

自动化带来的竞争优势

整合普玛宝全自动化激光切割系统,包括一台6 kW Platino Fiber 2.0激光切割设备以及一个午夜快车自动化料库后,Carpenteria Metallica Depedri的生产率提高了30%。

Biohort | 高级钣金加工

在上奥地利州黑尔措格斯多夫新建的Biohort制造工厂只一年便竣工。凭借领先的行业标准和优化的过程周期,储存空间解决方案的专家在诺伊费尔登总部新建了2号车间,为支持进一步增长创造了新的资源。

A&J precision sheetmetal | 硅谷作业车间凭借普玛宝设备取得成功

1995年,A & J Precision Sheetmetal Inc.在加利福尼亚州圣何塞创业之初,就凭借其生产精密零件的一流作业车间而在要求严苛的硅谷赢得了盛誉。