Five Seasons: bending automation clears the air for productivity

Automated bending technology dramatically changed Five Seasons production by reducing setup time and labor, delivering precision and allowing for faster delivery.

Automated bending technology dramatically changed Five Seasons production by reducing setup time and labor, delivering precision and allowing for faster delivery.

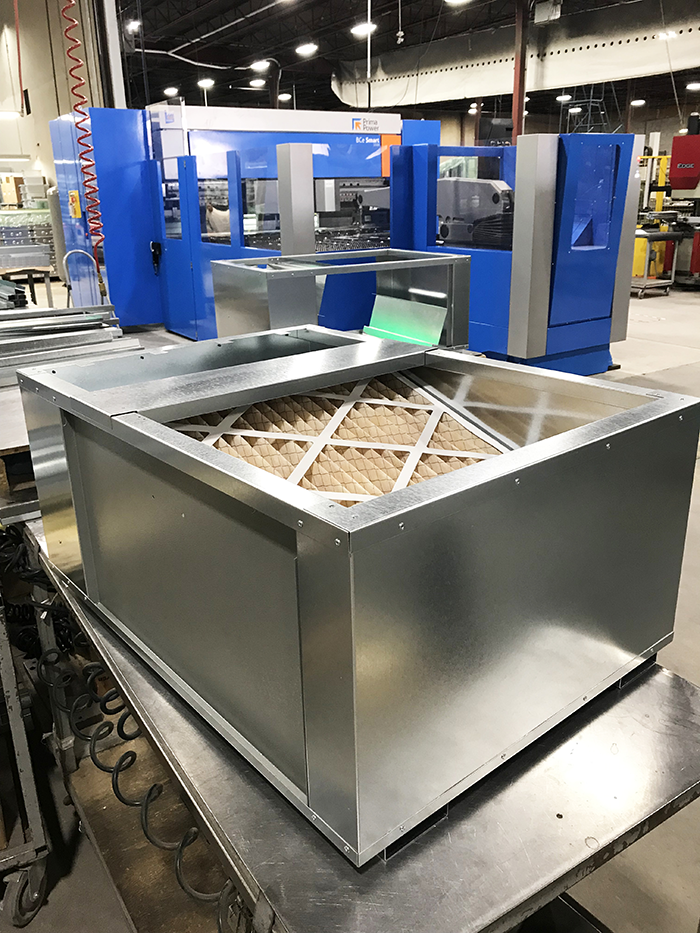

Since 1962, Five Seasons Comfort Limited & Electro Air Canada has designed and manufactured a complete line of residential, commercial, and industrial air cleaning systems. Their products include electronic, high-efficiency media, HEPA filtration systems, ultraviolet light, and photocatalytic filtration technologies. The company’s success is also due to a visionary outlook that focuses on helping people with allergies, asthma, and respiratory illnesses.

A family with a vision for cleaner air

Founder Howard David first became interested in electronic air cleaners because his daughters had allergies. Those two daughters, Caroline David, vice president of sales, and Mary-Louise Donadio, vice president of marketing, manage the company today. “Our father was ahead of his time,” explains Caroline David. “Back in the 1960s, he was very health conscious and doing yoga. Our product line has evolved dramatically. It started with the electronic and portable room air cleaner and now includes all mechanical air cleaners on furnaces, air handlers, heat pumps, furnace bottoms, platforms, etc.”

Transition to automated bending and productivity kick-off

Five Seasons moved into its current 100,000-square-foot facility in 1985 and is expanding, with an additional 30,000 square feet set to be added. In 2011, Five Seasons took its first step toward bending automation by purchasing a Prima Power Fast Bend to eliminate bottleneck delays in the bending operation. “We decided to move away from the traditional press brake operation and produce the parts on a servo-electric panel bending machine,” says David. The Fast Bend reduced labor-intensive tool setups, programming time, and part handling while offering flexibility to form different angles, hems, and multiple corner radii. Its features—including automatic tool change (ATC), an automatic feed table, and automatic inversion of positive and negative bending blades—allow for creating more bends per side in an automatic sequence without manual intervention.

Smart moves in bending

Following the success of the Fast Bend, Five Seasons purchased two additional Prima Power benders in 2021 and 2022. The Prima Power BCe Smart incorporates innovative technologies and enhanced intelligence that, combined with operator ability, make the machine easy to use while eliminating margins of error. It is ideal for both medium and low-volume production and lean production, guaranteeing precision and repeatability with reduced maintenance costs. BCe Smart’s compact layout, unique loading/unloading capability, and large working table allow for increased productivity in a single sequence. The machine is straightforward to use and does not require skilled operators. Due to the bar-code reader and the ATC system, its setup is automatic; it takes place in masked time and activates dynamic production queues. The high ergonomics and safety levels result from a series of features, such as the absence of physical barriers for manual loading, warning lights and acoustic signals to synchronize the loading and unloading. The interactive display guides the operator in the working phases to be carried out, such as the orientation of the pieces.

The Bce Smart benefits:

Speed, precision, reliability in every bend

“In addition to the two BCe Smart benders, we also purchased two Prima Power press brakes,” explains David. “Before making the purchase, we talked to three bender manufacturers. We showed all three the parts we wanted to build, but the other two companies couldn’t help us. Prima Power sent our parts to Italy to test whether they fit on the BCe Smart. As soon as they told us it would work, we bought the two machines. We chose the Prima Power machines due to our close relationship with the company. The people at Prima Power actually take the time to understand what we are manufacturing. They take care of us and help foster our growth.” According to David, the BCe Smart machines have dramatically increased productivity. “A complex job that we were bending on the press brakes took 8-9 minutes per part. The BCe Smart makes the part in 60-70 seconds. In addition, the press brake operator has to be very knowledgeable on tolerances, the machine, the part, etc. These days, it isn’t easy to find experienced press brake operators. But with the BCe Smart, we can hire someone with basic skills who doesn’t need engineering knowledge or be a technician. He doesn’t need to worry about tolerance or which side has to be bent first. The BCe Smart does everything.”

The service you can rely on

“We promise 48-hour delivery on all our orders,” continues David. “Prima Power and the BCe Smart machines have literally changed our company.” Dependable service is a key part of the partnership with Prima Power. “From the first day they installed the BCe Smart machines, Prima Power ensured they were operating efficiently,” adds Donadio. “If we have a programming question, the Prima Power technician stops what he is doing and is there for us. It is not just the machines that make Prima Power unique but also their customer satisfaction. When a problem needs to be addressed, Prima Power will respond immediately.”

Опыт в области

интеграции

Клиентоориенти

рованный подход

Высокоскоро

стные гибкие решения

Наш подход к устойчивому развитию: уменьшение нашего воздействия на планету также имеет экономические последствия.

Мы работаем по всему миру: найдите ближайшее к вам представительство Prima Power и свяжитесь с нами.

© PRIMA INDUSTRIE S.p.A., single-member company | Via Torino-Pianezza, 36 - 10093 COLLEGNO (TO) ITALIA | Share Capital €26.208.185 | VAT 03736080015 - C.C.I.A.A. Torino 582421 | Reg. Impr. Torino n. 03736080015