Express Robot Cell

EXPRESS ROBOT CELL

Minimal footprint. Maximum potential.

COMPACTNESS

Minimized footprint for installation even in limited spaces

FLEXIBILITY

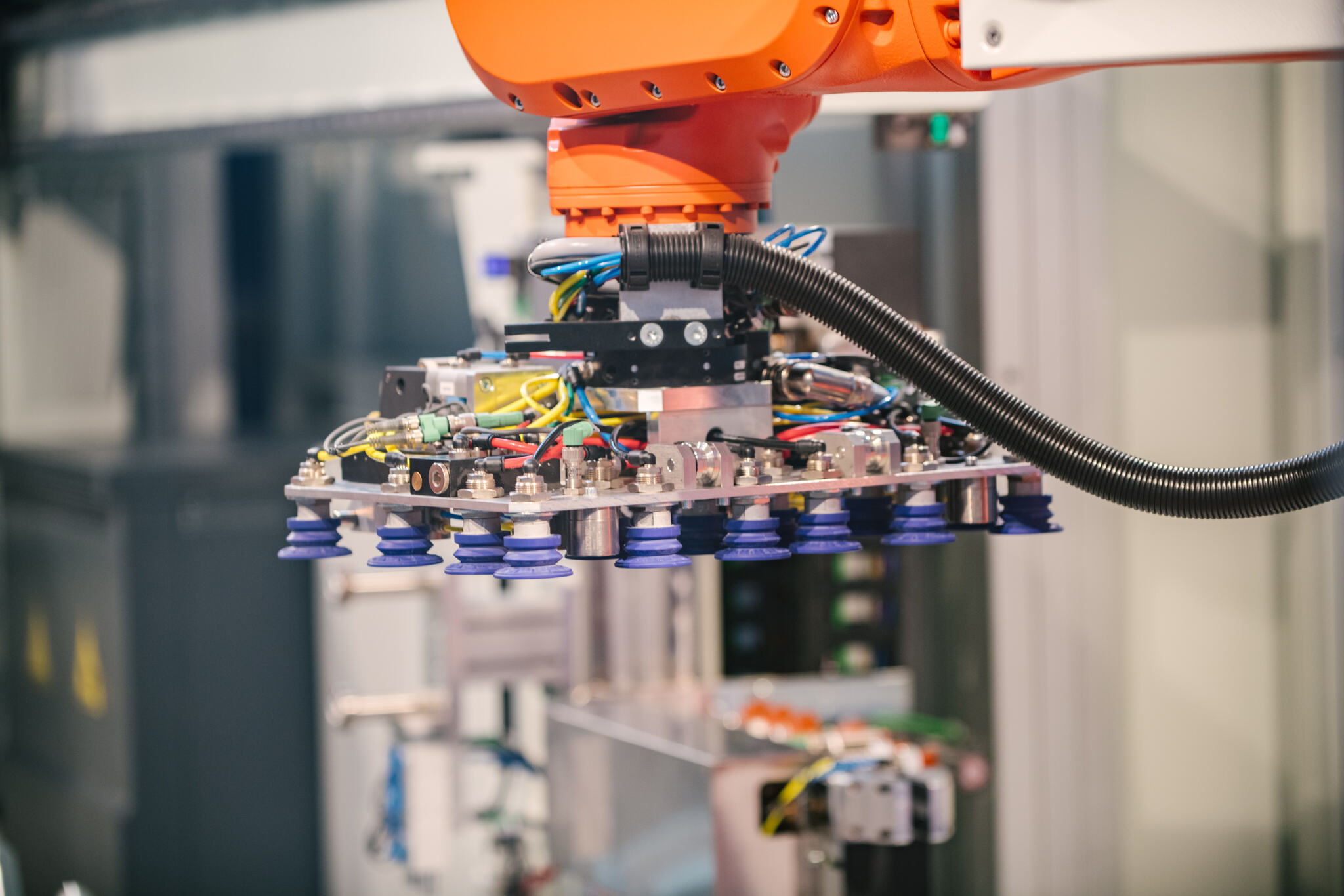

A wide variety of parts can be handled with just a small set of standard universal grippers

PRODUCTIVITY

Small size enables fast movements and short cycle time

PLUG & PLAY

All robot cell devices, robots included, are mounted on a metal platform splitting the Express Robot Cell into just two main elements (eP + robot & peripheral devices).

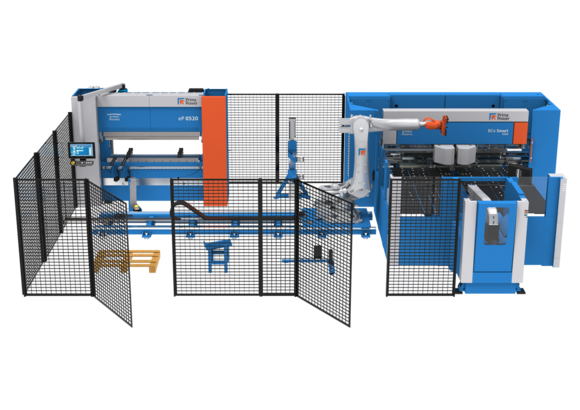

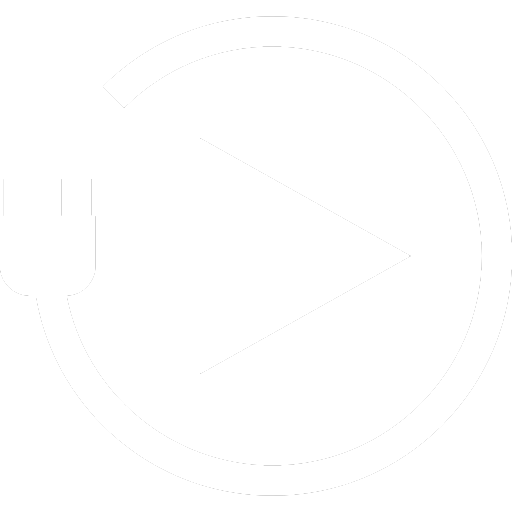

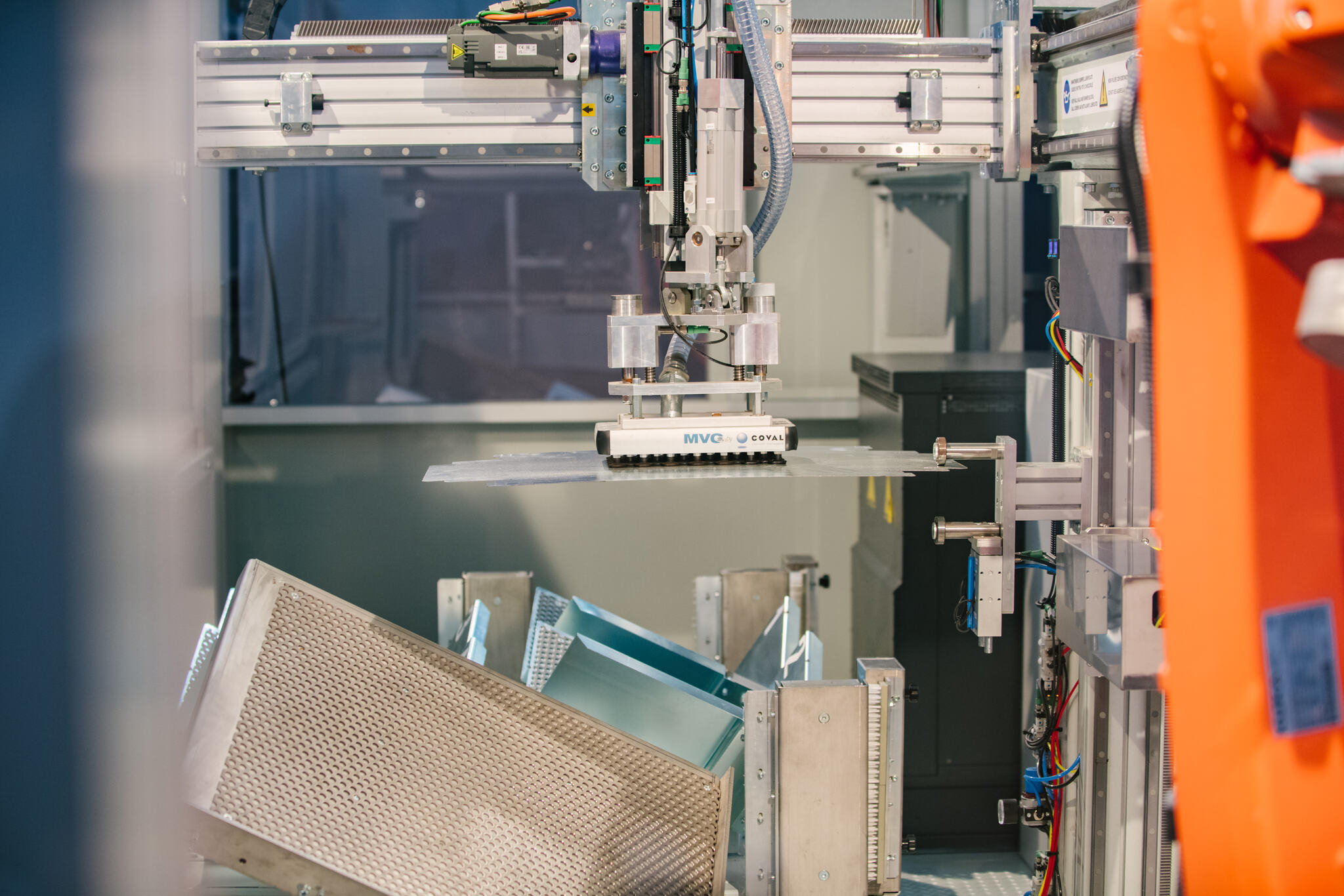

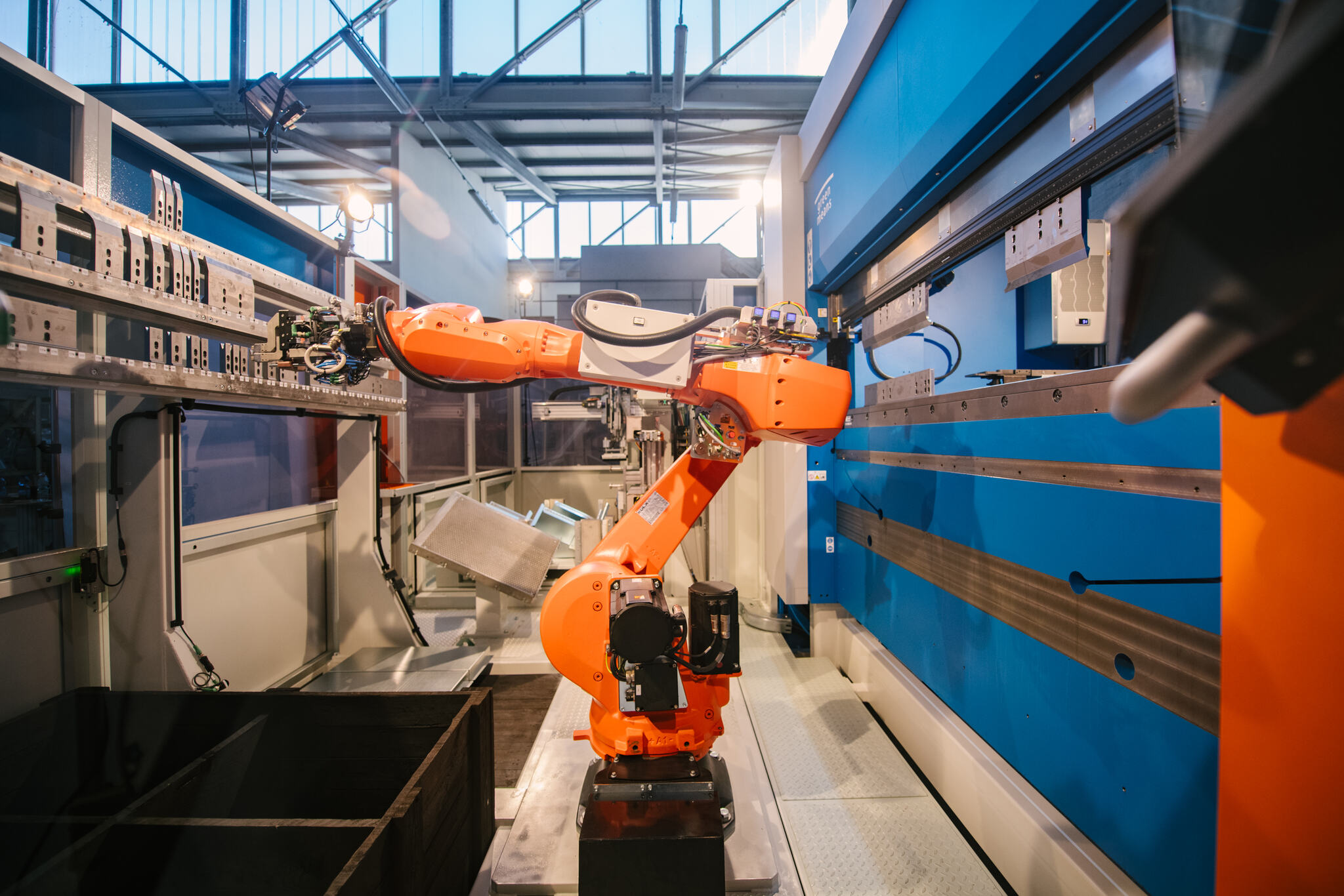

Express Robot Cell is the new compact robotic bending cell by Prima Power and it has been designed to highly perform in a minimal footprint, and includes:

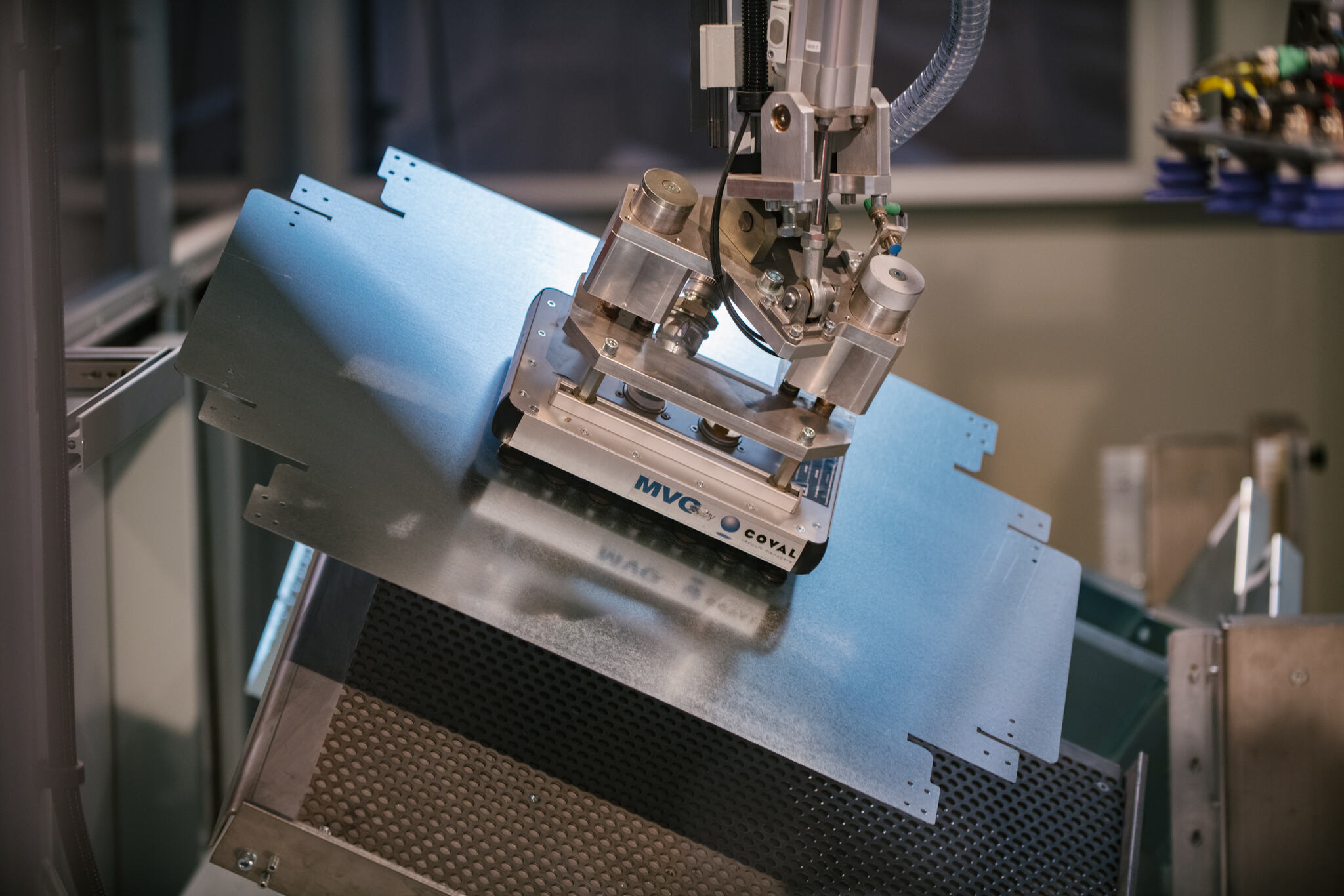

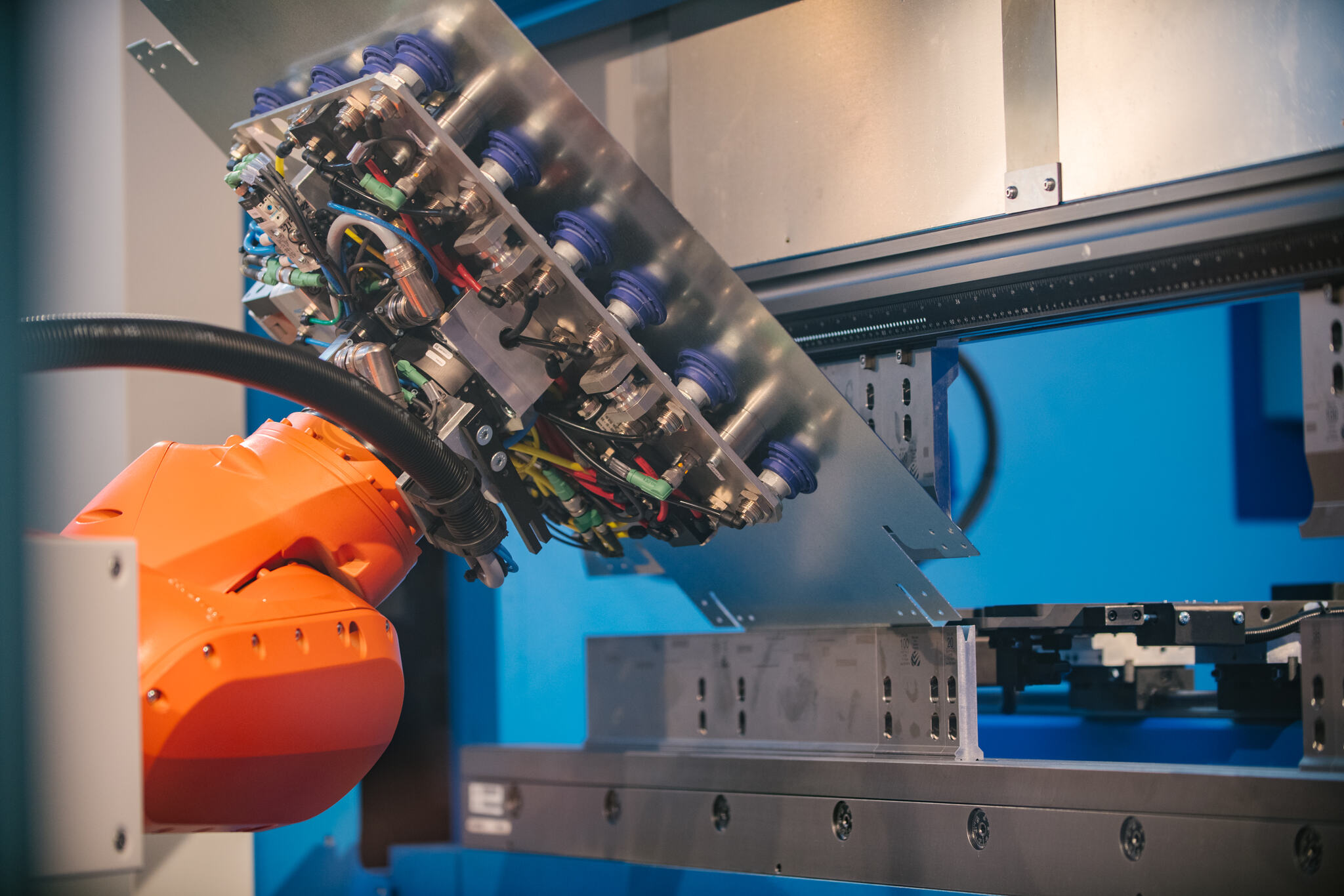

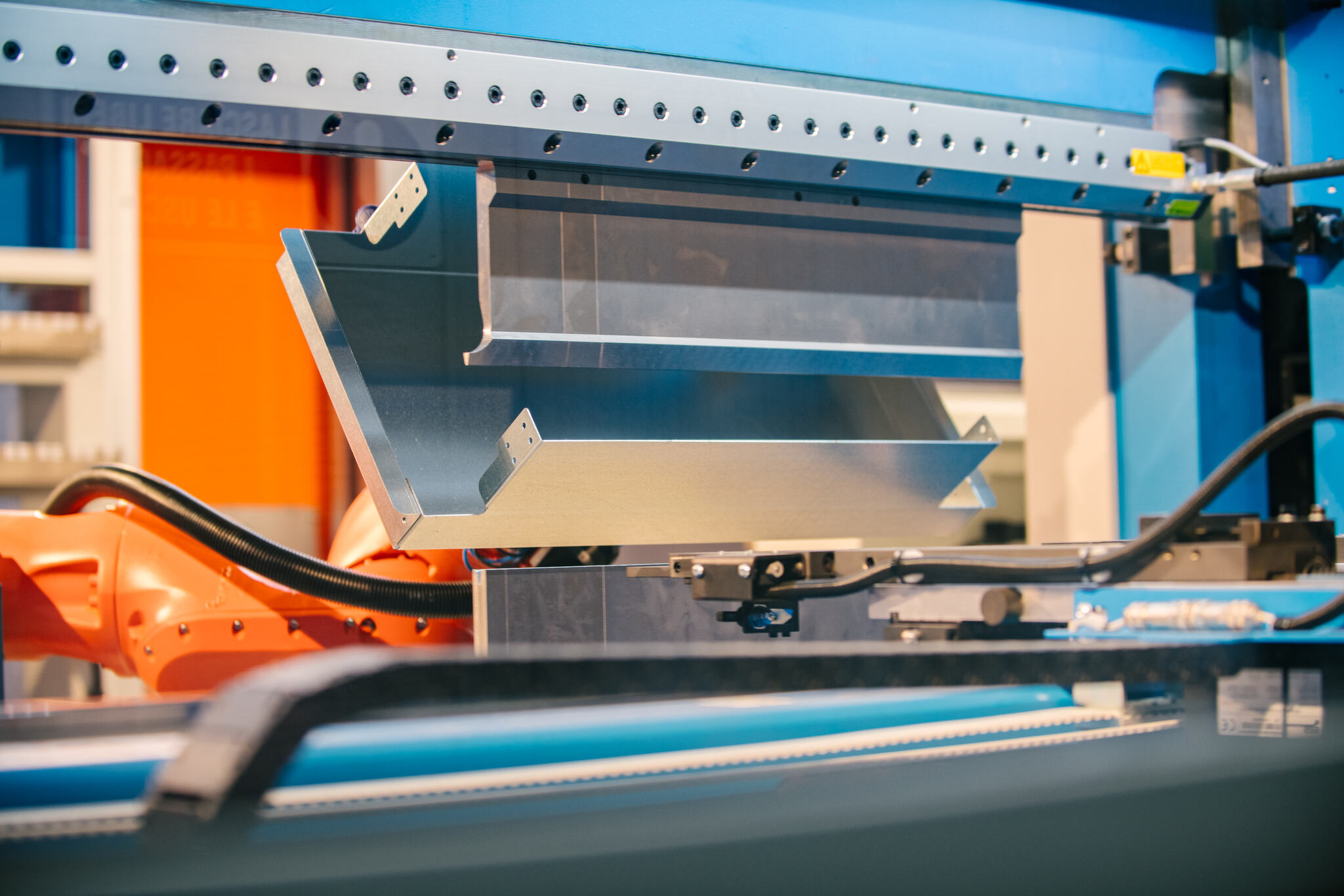

- one eP 0520 servo-electric press brake with 55 ton of bending force and 2320 mm of bending length

- a 6-axis industrial anthropomorphic robot for full part handling throughtout the bending cycle

- a 3-axis Cartesian loader for separating and centering the blanks in masked time while the robot is performing the bending

- a fully plug and play system with all devices pre-assembled on a single metal platform (robot, press brake, loader, centering table, sheet reverser, tool changer, gripper storage).

All the elements are housed in a reduced footprint, making this robot cell suitable even for space-constrained environments.

The compact design of this robot cell enables quick movement and short cycle times, resulting in high productivity. The industrial robot and the Cartesian loader work in parallel to further enhance the cell's efficiency.

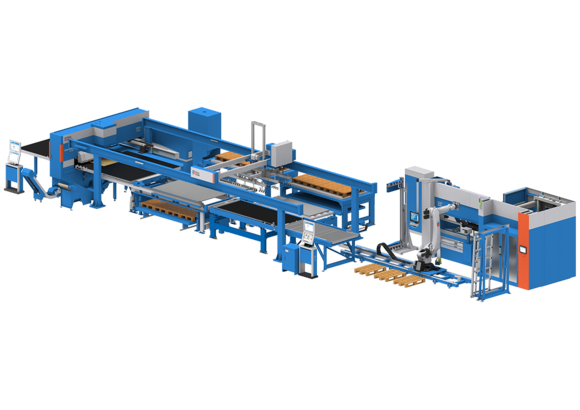

Express Robot Cell can be integrated with FMS storages, such as Prima Power’s Night Train, enabling continuous, unattended production.

The stand-alone version can be easily upgraded to a connected solution, with automated loading from storage systems and unloading to Automated Guided Vehicles (AGVs).

The system is built on a plug-and-play integrated metallic platform that houses the press brake and robot with peripherals in two main components, ensuring fast transport and easy installation.

This solution is the ideal choice for sectors like appliances, HVAC, automotive, metal furniture, and industrial components, handling small- to medium-sized parts, from simple to highly complex geometries. Leveraging the know-how of the Prima Power Robotics Integration Unit, the new system is designed to grow with the customer from a stand-alone unit to a fully connected production cell

| Max. and min. sheet dimension, Single loading cart | 800 x 600 mm 300 x 400 mm |

| Max. stack height, Single loading cart for larger sheets | 300 mm |

| Max. sheet weight | 15 kg |

Multistack unit, max. sheet dimension (4 loading carts for smaller sheets) | 300 x 400 mm |

Multistack unit, min. sheet dimension (Length x Width) | 130 x 40 mm, OR L= 100-130 mm if W>70 mm |

Multistack unit, max. stack height (4 loading carts for smaller sheets) | 150 mm |

| Input cart dimensions | 1200 x 800 mm |

| Unloading pallet & bin dimensions | 1200 x 800 mm |

| Unloading pallet, max. palletizing height | 610 mm |

| Discharge bin, max. collar height | 610 mm |

| Unloading belt width | 500 mm |

Optimize your Prima Power machine

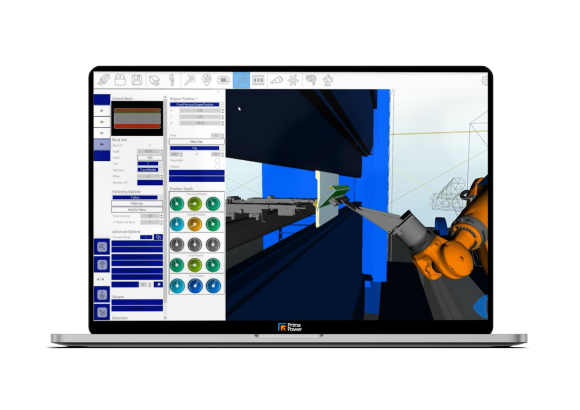

Tul-Robot

H.M.I.

L'interface opérateur qui permet de gérer le système et les programmes pièces pendant la phase de production.

Technologies connexes

RELATED AUTOMATIONS

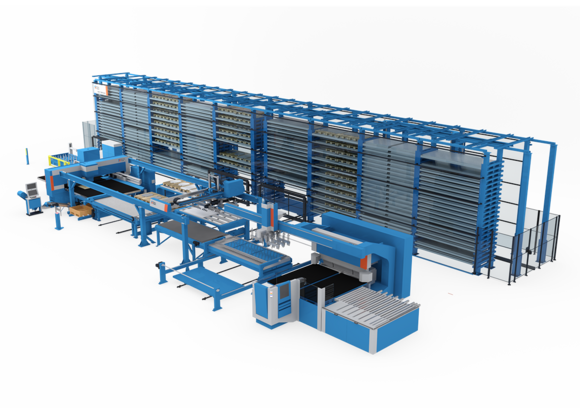

Night Train FMS®

SYSTÈMES DE FABRICATION FLEXIBLES

Solution de stockage technologique de pointe dans les systèmes de fabrication flexibles automatisés

Cellules de Pliage Robotisées

CELLULES DE PLIAGE ROBOTISÉES

Optimisation complète des performances entre vos mains

Take a look at the other products and choose the best solution

Cellules de Pliage Robotisées

CELLULES DE PLIAGE ROBOTISÉES

Optimisation complète des performances entre vos mains

Solutions d'Intégration Robotique

SOLUTIONS DE MANUTENTION DES MATÉRIAUX