NOVELTIES ALSO IN FINNISH

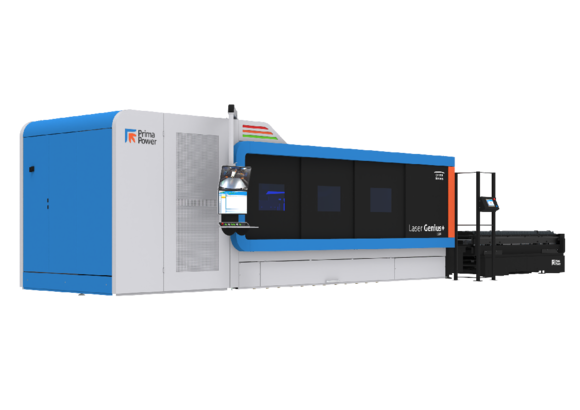

New technology was available for the new Laser Genius+ machine, as well as software and nesting in Finnish.

“With the new gas mixer, we get a noticeably better speed on the aluminum cut and the edge quality of the cuttings is also high. This was very important to us because we cut aluminum approx. 50% of our production. Also, a pallet changer, which you can get on either side of the machine, was new. We already knew about the high quality of Prima Power's service, but it was important and great for us that now we were also getting the nesting and the operator interface in Finnish. The software of a few other machine manufacturers was good in itself, but we don't want to use the machine in English. Finnish language was a big advantage to us”, Hiltunen notes.

THE NEW MACHINE BROUGHT EFFICIENCY

Since the machine was a full novelty, there were initially small adjustments to it, such as the first machines in the series often have. However, Prima Power offered support and assistance to bring the machine to its full operation.

“The machine is in full operation now and we could not be more satisfied. We got the first Laser Genius+ machine in Finland to respond to all the development needs we had in production. The machine is very fast to start and we can start cutting practically immediately. This was not possible with an older C02 type laser. Laser Genius+ machine is also more accurate and significantly faster, allowing competitiveness on the subcontracting side”, Hiltunen tells.

“The machine also fit into a tiny space whereby layout change in the hall was possible. Using the machine has been very easy, and we made significant savings when the software did not need to be updated at all”, Hiltunen states.

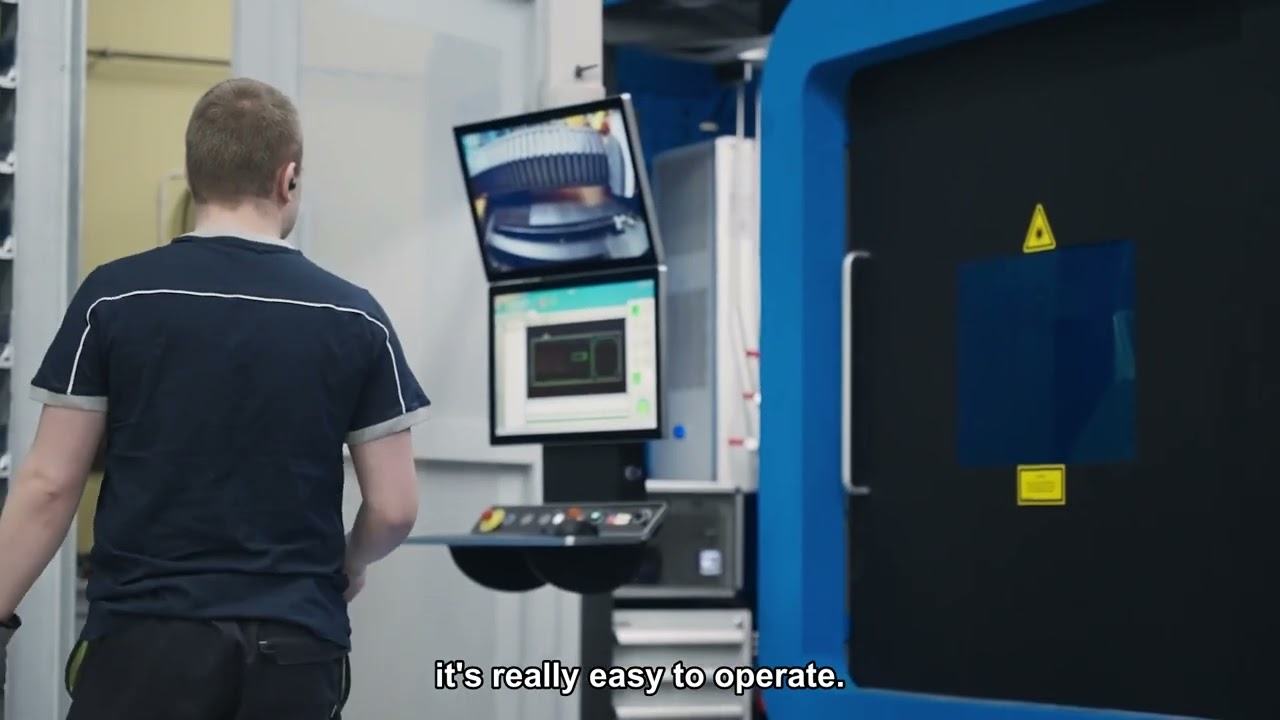

The machine operator, Toni Paananen, says the new machine has also brought new lessons to learn.

“For example, centering the nozzle with the camera is a great feature that saves a lot of time. The new machine is also very smooth to use, allowing practically no need for any adjustments in the settings ever again. Cutting quality is maintained and this saves time for the operator for unloading. I must say that you can’t manage by yourself with the machine when driving less than 1 mm thick materials. The nests’ cutting time is so short that the machine stands because the unloading cannot be done alone fast enough. With rush orders, we can take another man to help in order to get a new sheet just and just loaded in before the old one has been finished. You are getting sweaty at work these days, that’s not a good thing”, Paananen laughs.