Aperfeiçoamento da máquina

Sempre pontual graças às atualizações da Prima Power.

Uma moderna máquina de trabalho de chapas de metal pode receber o upgrade de novas características e funções durante o longo tempo de vida. A filosofia de design modular da Prima Power possibilita inúmeras soluções para otimizar desempenho e versatilidade enquanto aumenta do nível de automação, assim como garante que as máquinas e os sistemas de produção possam receber o upgrade mesmo anos após a instalação original (sujeito a análise individual de casos).

Com a integração de novas habilidades à tecnologia de produção já em uso, mesmo atividades de produção mais diversificadas podem ser atendidas, oferecendo produtividae aumentada. Planejamento e implementação de tais possibilidades é uma parte essencial dos serviços da Prima Power.

- Atualização da máquina à geração mais recente

- Aumento da produtividade

- Recursos de aprimoramento

- Indústria 4.0 (Fabricação inteligente)

- Vida útil prolongada

Soluções padrões e personalizadas

Upgrade padrão da máquina: opções que a cliente pode selecionar durante as negociações de compra de uma nova máquina. Esses tipos de upgrade estão também disponíveis depois da entrega.

Upgrade customizado da máquina: opções que não estavam disponíveis para a máquina no momento da compra. Neste caso, a Prima Power pode estudar uma solução customizada para a cliente.

Manter-se à frente da concorrência com a automação

Durante os anos, as automações vêm evoluindo significantemente, aumentando seu desempenho e adicionando mais funcionalidades. A Prima Power tem constantemente trabalhado para fazer o upgrade de produtos obsoletos com novas funcionalidades e oferecido desempenho similar ao de novas máquinas.

Quando uma cliente tem a necessidade de aumentar a automaçao, a Prima Power pode oferecer soluções de automação para as máquinas já existentes também.

O tempo de vida existenda do armazenamento Night Train da Prima Power pode ser estendido assim como as soluções de modernização.

As vantagens das atualizações de automação são:

- Novo PC servidor com sistema operativo atualizado

- Possibilidade de conectar novas máquinas

- Novo software de armazenamento da Tulus

- Menor investimento em comparação com a nova automação

- Investimento sustentável (podem ser reutilizadas estruturas de aço antigas)

Os nossos serviços

HISTÓRIAS DE SUCESSO

Saiba como o aperfeiçoamento das máquinas da Prima Power participaram do sucesso de uma empresa.

Fhiaba | Combined Technologies for Luxury Refrigeration

Fhiaba, a leading manufacturer of household appliances in the super-premium market for the preservation of food and fine wines, has upgraded its production line with innovative Prima Power technologies. The integration of advanced sheet metal processing systems has optimized processes, ensuring maximum flexibility and consistent quality in the final product.

Flama | Servo-electric technology driving efficiency and global growth

THANKS TO A LONG-STANDING AND SUCCESSFUL COLLABORATION WITH PRIMA POWER, SUBCONTRACTOR FLAMA HAS NOT ONLY MANAGED TO STAY ABREAST OF THE TIMES, BUT ALSO TO EXPAND ITS REACH BRILLIANTLY ACROSS NATIONAL BORDERS. ITS STRENGTH LIES IN BOTH ITS CLOSE-KNIT AND ENTERPRISING WORKFORCE AND ITS IMPRESSIVE FLEET OF MACHINERY, WHICH RIVALS THAT OF MUCH MORE STRUCTURED COMPANIES

IMPEA | Technological innovation at its best

IMPEA utilizes the most advanced technologies and collaborates with renowned partners, such as Prima Power for 2D and 3D laser cutting, to ensure high-quality standards, operational speed, and maximum flexibility in sheet metal processing.

Uma receita de inovação: o sucesso da Prática com a Prima Power

UMA LÍDER BRASILEIRA EM EQUIPAMENTOS PARA PANIFICAÇÃO FAZ PARCERIA COM A PRIMA POWER PARA PROMOVER EFICIÊNCIA E EXPANSÃO.

A PARCERIA DA PRÁTICA COM A PRIMA POWER IMPULSIONOU AVANÇOS SIGNIFICATIVOS EM SUA PRODUÇÃO, INCLUINDO NOVOS SISTEMAS DE AUTOMAÇÃO E EXPANSÃO GLOBAL.

Biohort | Deluxe sheet metal processing

The construction phase of the new Biohort manufacturing site in Herzogsdorf (Upper Austria) lasted just over a year. With cutting-edge industry standards and optimised process cycles, the specialist for storage space solutions created new resources for further growth with new Plant 2, an addition to its Neufelden headquarters.

Astra | Order and efficiency drive productivity, from first cut to finished product

Astra was founded just short of thirty years ago as the result of an innovative instinct which proved successful in just a few years: that stainless steel would become the technological material of the future.

Five Seasons: automação de dobra limpa o ambiente para produtividade

A tecnologia de dobra automatizada mudou drasticamente a produção da Five Seasons, reduzindo o tempo de preparação e a mão de obra, proporcionando precisão e permitindo entregas mais rápidas.

Proslat: transforming manufacturing in North America

Proslat integrated advanced automation to achieve a balanced production flow and expand retail operations. The Canadian company’s investment in Prima Power technology has greatly enhanced efficiency and set the stage for reshoring manufacturing jobs in North America.

Foco em automação Na subcontratada estoniana Alise Technic OÜ

A empresa de subcontratação Alise Technic OÜ, localizada em Pärnu, Estônia, foi fundada há 25 anos, em 2000. A história da empresa começou com um acordo para iniciar a fabricação de peças metálicas para portas de garagem para uma empresa alemã.

Um caminho rumo à automação e à sustentabilidade

Como a Woojin Plaimm melhorou a produtividade e a saúde da força de trabalho com as tecnologias da Prima Power.

Epta Gruppo - Gaining competitiveness through automation

How epta gruppo’s partnership with prima power is driving its industrialization and growth

50-year-old Piristeel invests in strong growth

Piristeel is Finland’s leading rainwater system and roof safety product manufacturer, especially known for its Pisko brand. The company celebrated its 50th anniversary in 2024

Guida Srl - Elevando a produção com tecnologia de corte a laser 2D

Uma empresa familiar italiana aumenta a eficiência em parceria com a Prima Power: a experiência da Guida Srl

Technoblech - Evolução impulsionada por soluções combinadas de corte

O poder transformador da inovação e liderança no setor de chapas metálicas

A Arte da Maestria em Metal: A História de De Castelli

Uma entrevista com Francesca Celato e Filippo Pisan, gerente de marketing da De Castelli e diretor artístico da De Castelli, chefe do departamento de P&D.

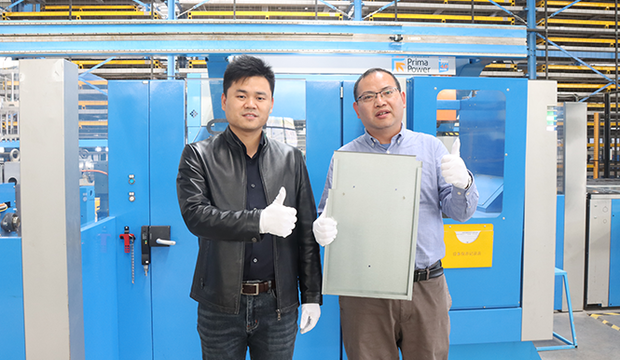

ZHILAI - AVANÇANDO COM FORÇA: LIDERANDO A INOVAÇÃO NA FABRICAÇÃO

Líder da indústria chinesa faz parceria com a Prima Power para forjar um novo futuro em custódia e entrega inteligentes

Systemair - Uma parceria de 30 anos produzindo marcos de produção excepcionais

A genialidade absoluta da abordagem de uma líder em ventilação para a automação

Chasestead - Cutting-edge investments to make production more efficient

Chasestead's latest acquisition in Fiber laser technology hits the mark

Zhixin - Revving up growth in the automotive industry

Zhixin’s expansion boost with 35 Prima Power’s laser-cutting machines.

Cadrex - Combining technologies to evolve capabilities

American company leverages Prima Power for streamlined process integration.

Dringenberg - Boosting production capacity through automation and integration

The leading German manufacturer optimized its processes and achieved higher flexibility thanks to Prima Power's fully automated and integrated PSBB line.

Resteghini - Growing together through innovation

From the introduction of laser technology, one of the first Platino machines marketed by Prima Power, to the recent challenge of the BCe 2720 automatic panel bender: the collaboration between the Milan-based contractor Resteghini and Prima Power is one of the fundamental elements of the success of this company, now in its fourth generation, capable of completing its evolution in a 4.0 perspective and continuing its process of development and innovation.

Long-term partner collaboration - Lojer Oy

Lojer Oy is the largest manufacturer of hospital and healthcare furniture in the Nordic countries. The company operates three factories in Finland in Sastamala, Hollola and Kempele, with the Sastamala factory serving as a central unit.

Glenn Metalcraft, going Big on 3D Fiber Laser: A Perfect Fit for Heavy-Gauge Metal Spinner

Sometimes size matters. Both in terms of business growth, as well as the methods and machinery used to facilitate success especially as the size (dimensions) of your parts get bigger for new applications. As businesses grow, they also must increasingly rely on strategic partnerships with key customers and suppliers, adopt new technologies and processes, take calculated risks including acquisitions and continually become more efficient.

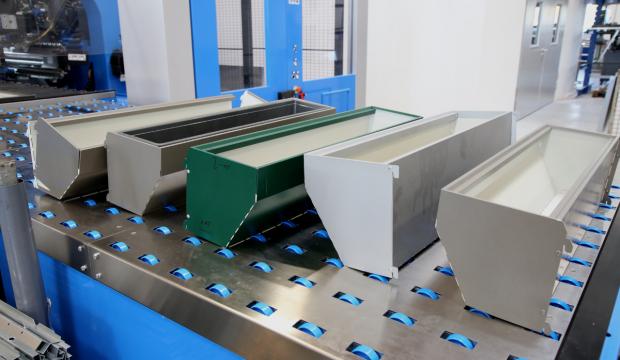

C & I Enclosures - Punch-Shear Combo Pushes Productivity Sky High

At electrical-enclosure manufacturer C & I Enclosures, which sought a new state-of- the-art machine able to transform parts through

to final production stages without the need for secondary operations, avoiding costly material handling between sheet loading, punching

and shearing, and part sorting and unloading.

Pipemodul Oy, strengthening business values through technology

Pipemodul Oy, a Finnish family business producing prefabricated pipeline and cable boxes, chose Prima Power’s servo-electric press brake, enhancing its commitment to responsible manufacturing practices.

Metaltecnica, Italian passion for the catering industry worldwide

Metaltecnica manufactures equipment designed to maximize efficiency and reduce energy consumption, while also boosting performance to enable maximum hygiene in kitchens around the world. This wide range of solutions is divided into six product categories and includes a number of high-performance Prima Power plants in their manufacture.

Bierkühl Oy and their Laser Genius+

Bierkühl Oy, a beverage equipment manufacturer from Mikkeli, is known for its innovative Finnish expertise and quality. The customers include leading operators and breweries in the beverage industry. The company is also a contract manufacturer for machines intended for cleaning ventilation ducts and dust-free renovation work under its own Bos® Cleantec brand.

Cooperation, competence and strong machinery base - Mittametalli Oy

The roots of Mittametalli Oy, founded in 2012, go back more than forty years, when the company's main Owner and Director Jari Kolehmainen, started working at his father's company Lankapaja.

DAV, Innovators by tradition

Industry 4.0 before the definition even existed and always oriented towards investing in new technologies, the DAV metalworks company in Rho has decided to focus on a highly automated Combi Genius 1530 laser and punching machine from Prima Power to increase production efficiency and expand the range of machining operations that can be performed directly on the machine.

Raytec, always with an eye toward automation

Raytec LLC, a fourth-generation Pennsylvania family business, has experienced rapid expansion by investing in Prima Power equipment and turning their operation from completely manual to fully automated.

Laitila Components and Coating invests in a combi machine

Managing Director Kai Salo and Production Director Petri Kallio from Laitila Coating Oy visited the Seinäjoki factory at the end of April 2020. The program included the handover of the Combi Sharp 1225 machine from the latest Prima Power investment, as well as the connected Compact Express automation device, and customer-specific test runs.

Uudenmaan Ohutlevy, the desire to grow and develop prompted investment

Uudenmaan Ohutlevy Oy, based in Kerava, Finland, manufactures sheet metal components and assemblies for machinery and equipment manufacturers in various industries. The vast majority of production is individual components, as well as various configurations, but also welded assemblies. The greatest volume of outgoing goods is products that are cut, edged, tapped and otherwise harnessed with different fasteners.

The global aiot innovator invests in state-of-the-art equipment to produce high value-added products

SUNSEA AIOT Technology’s subsidiary in Zhuhai pioneers smart factory innovation with cutting-edge machinery. The world-class factory serves both domestic and international markets.

Control Express Finland, The new combination machine brought quality and certainty

Established nearly 30 years ago, Control Express Finland Oy, or CEF, started its operations with IT related projects and the import of industrial electronics.

Rappo, New technologies, old partners. The value of great customer care

At Prima Power, we strive to build long-lasting business relationships based on mutual trust and respect. But don’t take our word for it: our customer Rappo, whom we’ve worked with for 25 years, shares his point of view.

Challenging times demand bold decisions, Relicomp

Relicomp makes a strong investment for quality and product consistency.

“We find that Prima Power’s machines have brought the fastest return on these investments”

De Wave, Efficiency and productivity take hold

They ply the seas across the world, hosting anywhere from a few dozen to a few thousand people. we’re talking about the cruise ships, large yachts and river boats for which the De Wave group produces various types of on-board furnishings and fittings, all created using integrated technologies of a high-performance automatic line by Prima Power

Paramount Components

Job shop powers through bending bottlenecks

Paramount Components employs semi-automatic panel bender to manage time, talent crunch

Clivet, going servo-electric for growth

As one of the largest producers of heat pumps and chillers, Clivet has chosen Prima Power’s servo-electric technology to modernise its sheet metal processing plant with highly automated solutions that are fully Industry 4.0 integrated. The PSBB line represents the heart of the department, managing the entire production process with stations for punching, shearing, buffering and bending.

Dunbarton, meeting objectives

Fabricator achieves higher productivity and accuracy with servo-electric technology.

JST Power Equipment, having the right facilities to say ‘yes’ to clients is priceless.

Switchgear lineups are engineered-to-order products with a lot of variation among jobs, including fabricated sheet metal parts. Enabling the new JST Power Equipment switchgear-manufacturing plant to excel at taking on low-volume production: an automated punch-shear combination machine.

Vacuum Technology Inc., High-Tech manufacturer chooses Platino Fiber Laser

Laser cutting addition speeds production for a Tennessee supplier of gas-leak-testing technology while freeing waterjet cutting machines for other work. It’s an all-around win for Vacuum Technology Inc.

Scott Springfield Mfg, a compact solution for customer success

Scott Springfield Sfg, inc. in Calgary, Canada, is a leading supplier of custom air handling systems, utilizing the latest technologies to provide its customers with a flexible solution to their air handler needs.

Gi.Metal, ready for a batch of productivity

If Italian cuisine is one of the most famous and renowned in the world, then this is definitely thanks to chefs who have exported the recipe, but those who produce kitchen utensils also play a very important role. Such is the case for Gi.Metal, who specialises in the manufacture of pizzeria equipment, which use prima power lasers in the cutting process.

Rizzato SpA, modular technology and automation to stay one step ahead

Rizzato S.p.A., an Italian leader in subcontracting for the processing of stainless steel and other materials for semi-finished and finished products, is in constant evolution for excellence. At the base of its growth, a strong entrepreneurial spirit and a continuous commitment to always be at the forefront of production technologies and automation. The farsighted choice of a modular automatic storage solution has kept the company one step ahead for over 20 years, adapting to growing production needs.

Stremet Oy and and the future in growth and partnerships

Stremet oy is a finnish sub-contracting company based in Salo, south-western Finland, with over 25 years of solid experience in its field.

Schulthess Maschinen - The power of three

The eco-efficient cell with panel bender, press brake and industrial robot.

Most organizations today claim sustainability is one of their core values, yet it is not so common to find companies that are able to set better standards for environmental protection with their products. Schulthess Maschinen AG is one of these few game changers, thanks to its exceptionally energy-efficient washing machines and dryers.

Steelcomp invests in a new factory with advanced automation

Steelcomp Oy will continue its strong production development work in its operations in Kauhava, Finland. With a newly completed plant extending over more than 5,000 square meters and extensive investments in Prima Power production automation, the company is on the road to strong growth for years to come.

Why a metal fabricator jumped into panel bending

FlexMet continues to change its manufacturing focus, now with a new bending tool. A new product focus and a desire to automate bending are just two of the reasons that FlexMet, Franklin, Tenn., operates a panel bending machine instead of relying on more press brakes for its bending needs.

A look at the technology behind turnkey organic poultry plants

SKA srl manufactures poultry systems for organic free-range farming with high levels of product customisation by taking advantage of innovative Prima Power technology.

Riding the Night Train to Higher Productivity

The Minerva Group in Bologna, Italy is a company that truly embodies skills, technology, and entrepreneurial spirit.

A&J precision sheetmetal | Silicon Valley Job Shop Achieves Success with Prima Power Machines

Since A & J Precision Sheetmetal Inc., San Jose, CA, first opened its doors in 1995, the company has earned a stellar reputation as a leading job shop producing high-quality precision parts in the demanding Silicon Valley.

Alvi | A perfect combination for the medical sector

Aluminum and stainless steel are the materials used by Alvi to produce trolleys for the hospital, laundry, retirement home, hotel, industrial and textile sectors.

ATP | Flexibility and precision in the manufacture of custom rack cabinets

After having chosen Prima Power as the supplier of the company's very first laser cutting machine, ATP decided to continue focusing on the quality and technology of the Italian manufacturer by also investing in a servo-electric bending machine

Automation as a Competitive Edge

Thanks to integrating a Prima Power fully-automatic laser cutting system, consisting of a 6 kW Platino Fiber 2.0 laser cutting machine, along with a Night Train automated warehouse, Carpenteria Metallica Depedri has been able to increase productivity by 30%.

Platino Fiber Laser & Tower clear the air for higher productivity at ventilation manufacturer

Soler & Palau (S&P) Ventilation Group is the world’s leading fan manufacturer. The company offers a wide range of ventilation products benefiting from over 60 years of experience within the industry.

Brink Industrial | Vision: that all-human drive towards evolution

Discover Brink and Prima Power partnership, a success story made of human connections.

Advanced Lasers Meet Diverse Needs of Tooling Group - Diversified Tooling

Advanced laser technology has been instrumental in making the four affiliated companies of the Diversified Tooling Group, Madison Heights, Mich., into a leading supplier of single-source manufacturing solutions to the automotive, heavy truck, defense, industrial equipment, power generation, rail, and foundry i

Future fit with the punch laser machine

Eisenwerk Wittigsthal GmbH invests in a punch-laser system so as to be ready for the digital future.

Prima Power EBe Express Bender Increases Productivity & Quality at Georgia Job Shop

When Randy Williams opened his job shop, he was already a seasoned fabricator. “I grew up with metal fabrication,” explains Williams. “My dad was an aerospace engineer who built trampolines part-time when I was 10 years old, and I helped build parts in the basement. His business evolved into making ferris wheels and other portable amusement rides, but eventually the liability insurance became too challenging for the small company.”

Facing Adversity and Winning with Prima Power Equipment

How many job shops could lose a customer that accounted for 98% of their business and recover in just a few years? Elm Machining was faced with that scenario several years ago.

Top performance

With over a decade of experience in laser cutting and sheet metal bending, Laserlam constantly looks to new solutions to increase its productivity, such as Prima Power’s new 2D Laser Genius+.

30+ Years of experience and still growing

Lasercraft USA Knows 5-Axis Laser Cutting Backed By 30 Years Experience And The Latest Technology -- Success Grows Using A Newly Acquired LASERDYNE® 430 With BeamDirector®

Snow- and ice-free roads even faster now

After about thirty years, Giletta, a company that is part of the Bucher Municipal group, a landmark in the production and sale of snow removal machines and equipment, decided to bring the steelwork department back in-house by installing a new fiber laser cutting system and a servo-electric press brake both by Prima Power.

Punch-Shear Combo – A Labor Saver

Shear and punch fabrication of sheetmetal parts at custom door manufacturer LaForce, Inc. more than triples thanks to implementation of a new servo-electric punch-shear combination machine.

Prima Power PSBB Helps Power Generation Giant Build Flexible Manufacturing System

Headquartered in Spain, with 8 production centers, 13 subsidiaries worldwide, and a global network made up of 1,000 employees who work closely with more than 130 distributors around the world, HIMOINSA, part of the Yanmar Group, is one of the top global giants that designs, manufactures and distributes power generation equipment.

New investments create productivity at Halton’s Kausala factory

Halton Group is the world's leading provider of indoor air solutions. Indoor air solutions are divided into four segments: Marine, Health, Foodservice, and Buildings

Automatic cutting, storing, and sorting, with 850 million combinations

Specialising in manufacturing components and accessories for HVAC systems, Tecno-Ventil internally manages the entire production chain: assembled products created from 15,000 primary parts, are combined to create innovative, intelligent, and stylish solutions. A process where the sheet metal department makes the most of a high-performance, continuously running Prima Power system consisting of a fiber laser cutting machine, a storage unit, and an automatic parts sorting system.

New beginnings - Supporting ARC Industries’ new launch

Machine manufacturers are rarely confronted with the number of requirements Arc Industries presented – yet great energy and passion for a job well done allowed a new business relationship to flourish.

The irreplaceable value of customer care

As a leader in the Chinese high-tech market and beyond, CHINT needs the most flexible, integrated, and powerful equipment to meet the requirements of an increasingly competitive market. The company’s ability to recognize emerging trends and keep up with innovation has allowed it to make the right investments for business success and almost 30 years of growth in a technology-driven field.

Increase flexibility, productivity and savings at the same time

Lankapaja Corporation is one of the biggest and best-known sheet metal subcontractors in Finland, and manufactures a wide range of products such as store furniture, trolleys, steel components, chair and table frames, and racks. The company started as a lampshade manufacturer as far back as 1935, but its capacity and reputation today allow it to deliver comprehensive solutions for shop furnishing or logistics systems for laundries and hotels, for example.

Precision fabrication and prototype evolution with Prima Power 3D fiber lasers

From humble beginnings to top supplier of precision metal fabrication, prototype manufacturing, and short-run production for Tier 1 suppliers and OEMs in the Midwest: Duggan Manufacturing looks back on 20 years of hard work, smart investments, and great customer service, with Prima Power at its side.