Um caminho rumo à automação e à sustentabilidade

Como a Woojin Plaimm melhorou a produtividade e a saúde da força de trabalho com as tecnologias da Prima Power.

ENFRENTANDO DESAFIOS ATRAVÉS DA INOVAÇÃO

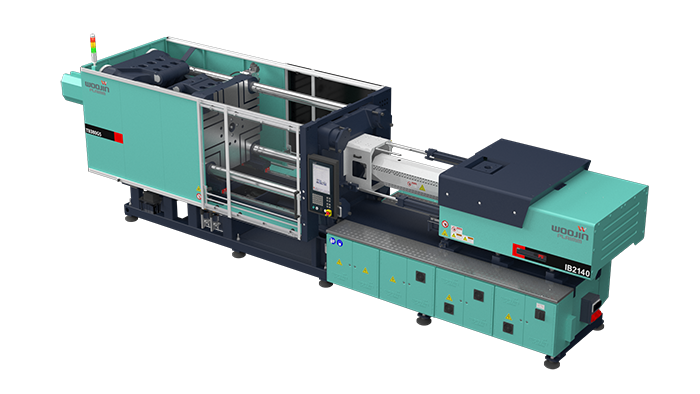

Fundada em 1985, a Woojin Plaimm tornou-se uma fabricante de máquinas de moldagem por injeção reconhecida mundialmente, listada no KOSPI (Índice Composto de Preços de Ações da Coreia). Como muitas empresas de manufatura, a Woojin Plaimm enfrenta desafios como o fortalecimento da competitividade global e a implementação da gestão ESG (Ambiental, Social e de Governança). Em particular, questões como o envelhecimento da força de trabalho e o risco de distúrbios musculoesqueléticos eram preocupações críticas que precisavam ser abordadas para solidificar sua posição no setor de fabricação de máquinas de moldagem por injeção. Na busca por soluções para esses desafios, a Woojin Plaimm recorreu aos sistemas automáticos de fabricação de chapas metálicas da Prima Power, que melhoraram a velocidade de trabalho, a flexibilidade e a eficiência da força de trabalho em um curto período de tempo.

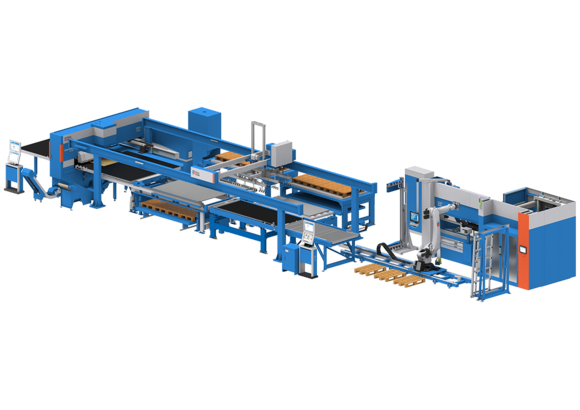

SIMPLIFICANDO OS PROCESSOS DE CHAPA METÁLICA COM A AUTOMAÇÃO DE LINHA LPBB

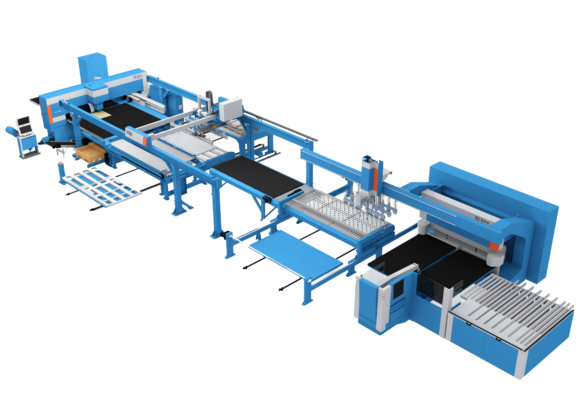

A Woojin Plaimm terceirizava diversos processos de produção, como muitas grandes empresas coreanas, mas essa abordagem frequentemente apresentava limitações. O Sr. Sunho Kim, Gerente Geral da Equipe de Chapas Metálicas da Woojin Plaimm, explicou: "Embora a terceirização atendesse às nossas necessidades, faltavam oportunidades de melhoria, e cumprir os prazos de entrega era desafiador. A Prima Power incorporou rapidamente nosso feedback, permitindo a rápida automação de nossa linha de produção.""A Linha LPBB é o principal fator que contribui para o aprimoramento dos processos de chapas metálicas da WOOJIN PLAIMM. Este Sistema de Manufatura Flexível (FMS) integra corte a laser, puncionamento, polimento e dobra, oferecendo alta produtividade por meio de tecnologia modular e gerenciamento inteligente do fluxo de materiais. Sobre a Linha LPBB da Prima Power, o Sr. Kim observou: “Anteriormente, os materiais processados por puncionamento manual ou máquinas de corte a laser precisavam ser transportados para máquinas de dobra com empilhadeiras ou guindastes. O sistema da Prima Power elimina essa etapa, conectando diretamente o puncionamento e o corte a laser à dobra. Tarefas que antes levavam mais de três dias com cerca de 20 funcionários agora podem ser concluídas em apenas 8 horas.”

A Linha LPBB também reduziu a força de trabalho necessária na linha de produção de 20 para apenas 3, reduzindo significativamente os custos com mão de obra. Além disso, a operação contínua das máquinas em linha garante a qualidade consistente do produto.

DOS GANHOS DE EFICIÊNCIA À GESTÃO ESG COM MÁQUINAS DE CORTE A LASER

Em 2022, com o reconhecimento da gestão ESG, Woojin Plaimm reagiu proativamente, recebendo o Prêmio do Governador de Chungcheongbuk-do no Korea ESG Management Awards.

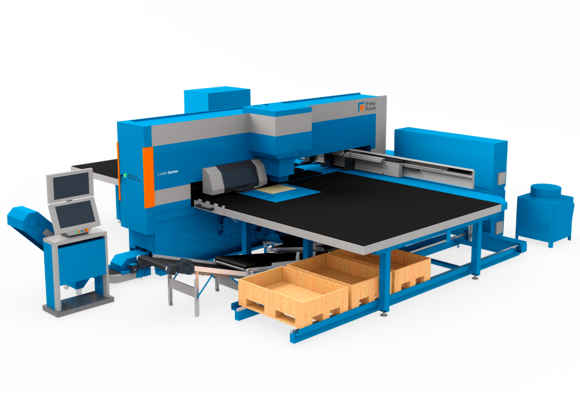

A Combi Genius, uma máquina combinada de puncionamento/laser fornecida pela Prima Power, oferece alta produtividade mesmo em espaços confinados e é compatível com diversas soluções de automação, garantindo produtividade e flexibilidade ideais.

Outra máquina a laser, a Laser Genius+, estabelece um novo padrão em corte a laser 2D com sua operação totalmente automática, desde o carregamento do material até a classificação e o empilhamento. Ela oferece precisão superior graças às suas estruturas estáticas e dinâmicas altamente rígidas. Equipada com motores de alta velocidade, ela atinge as velocidades de corte mais rápidas do mercado e possui um sistema de troca automática de paletes de alta velocidade, um trocador automático de bicos com 20 estações e um sistema de controle de processo em tempo real.

O Sr. Kim compartilhou suas expectativas para as máquinas a laser da Prima Power, afirmando: ""Woojin Plaimm dá ênfase significativa à gestão ESG, particularmente à preservação do meio ambiente e à conservação de energia, onde a automação é Essencial. As máquinas a laser da Prima Power aumentam a velocidade nessas áreas, facilitando atividades ESG relacionadas ao uso de energia.”

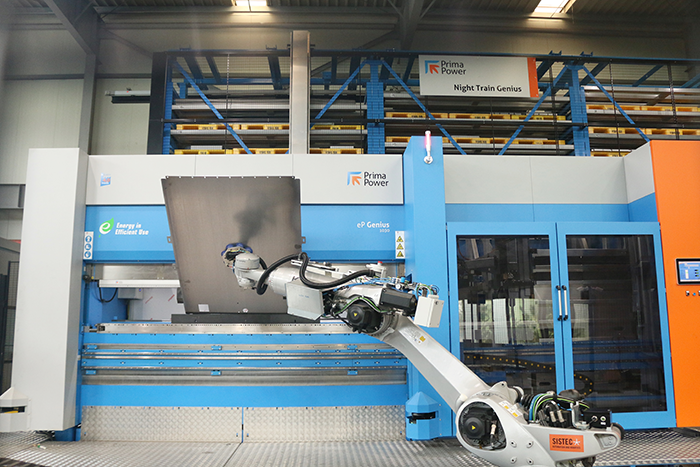

ALCANÇANDO O AGUARDO DA AUTOMAÇÃO COM AS SOLUÇÕES ROBÓTICAS DA PRIMA POWER

Robôs são essenciais para alcançar a automação completa em locais de produção. Woojin Plaimm utiliza robôs em diversos processos, aumentando a eficiência por meio da integração com as máquinas automáticas da Prima Power.As soluções robóticas da Prima Power permitem integração e automação de alto nível, incluindo programação, planejamento de gestão da produção em ERP, feedback e relatórios. Essas soluções são ideais para volumes de produção flutuantes e peças com formatos diversos, integrando etapas complexas de produção em um único sistema para aumentar a produtividade e reduzir custos.

ALCANÇANDO A AUTOMAÇÃO EM LOGÍSTICA COM O NIGHT TRAIN FMS®

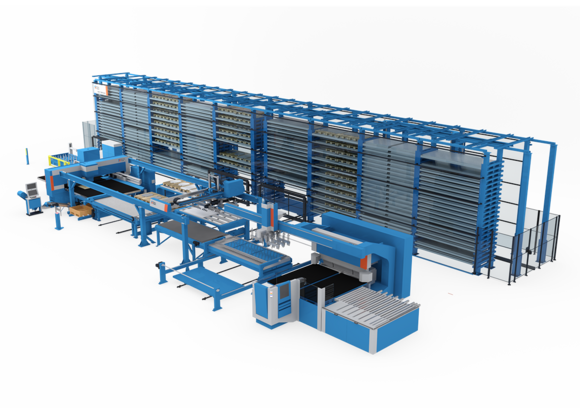

O Night Train FMS (Sistema de Armazenamento e Manufatura Flexível), apresentado à Woojin Plaimm pela Prima Power, é uma solução líder para o manuseio automatizado de materiais e produtos semiacabados, respaldada por mais de 30 anos de experiência e engenharia avançada.

Com uma estrutura de guindaste e prateleiras de baixo perfil, o Night Train FMS oferece excelente capacidade de armazenamento com espaço mínimo para instalação. Ele automatiza o fluxo de materiais e informações, integrando etapas individuais de fabricação em um processo flexível. Além disso, otimiza a produção de chapas metálicas dentro da ampla gama de máquinas-ferramentas de alto desempenho, células integradas, soluções automatizadas de manuseio de materiais e software da Prima Power. O Sr. Kim destacou: “Um dos motivos para o envelhecimento da força de trabalho na indústria são as más condições de trabalho. Espera-se que as soluções automáticas de chapas metálicas da Prima Power reduzam significativamente a taxa de ocorrência de distúrbios musculoesqueléticos causados pela movimentação de produtos pesados, mantendo um ambiente limpo e seguro.” Ele ainda observou: “Com as soluções automáticas da Prima Power, prevemos não apenas a produção em massa de produtos padronizados, mas também respostas rápidas às demandas urgentes dos clientes.”

Are you looking for a similar solution for your company? Find it here

Night Train FMS®

SISTEMAS DE FABRICO FLEXÍVEIS

Solução de armazenamento de tecnologia líder em sistemas de manufaturação flexíveis automatizados

Combi Genius

MÁQUINAS COMBINADAS DE PERFURAÇÃO E CORTE A LASER

Perfuração + Corte a laser = Economia de produção superior

1+1>2

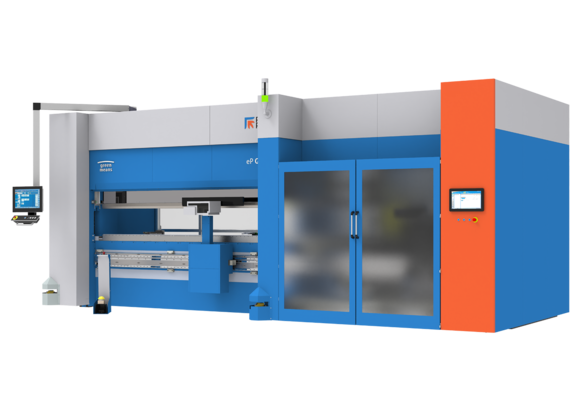

eP Genius

TRAVÕES DE PRESSÃO

Solução de dobragem servoelétrica eficiente com um armazenamento rápido e automático de troca de ferramentas

Soluções de Integração de Robótica

SOLUÇÕES DE MANUSEIO DE MATERIAIS