Focus on automation at Estonian subcontractor Alise Technic OÜ

Subcontracting company Alise Technic OÜ, located in Pärnu, Estonia, was established 25 years ago, in 2000. The history of the company started with an agreement to start manufacturing metal parts for garage doors for a German company.

At that time Estonia was not yet a part of the EU and the export to Germany was very time-consuming and difficult. The trucks could stay at the border for many days. The German company then decided to do the manufacturing and assembly of the parts in Germany and Alise Technic continued subcontracting to other companies.

Since those days, Alise Technic has grown to be a versatile subcontracting company serving dozens of customers from versatile industrial sectors like building industry, machinery, car and furniture manufacturing, as well as the medical and electronics sectors.

A leading guideline is to have a wide portfolio of customers, with about a dozen main customers, where none of them exceed 25% of the production capacity of the company. In this way the operation of the company stays balanced and is not negatively affected by the recession of one industry or company.

The company currently has 40 employees of which 24 are working in production and 16 in the offices and supporting functions.

Metal working industry in Estonia

Estonia, located south of Finland by the Baltic Sea, has quite a small metal industry and 99 % of its production is exported by mainly Finnish, Swedish and German companies, who are subcontracting in Estonia. Some subcontracting is also done in Latvia.

There are many subcontracting companies in Estonia working for international companies, and they don’t manufacture own products. In the city of Pärnu, there are 5 companies working in metal subcontracting.

"Generally, it is difficult to find staff for metal industry in Estonia. This is partly because people don’t know the industry so well, and partly because there is no sufficient education for metal working in Estonia. The education is more focused on welding and wood CNC machining, not sheet metal working." says CEO Valev-Heiki Allik.

Alise Technic has tried to tackle this e.g. by creating some courses with local schools for the sheet metal working. In this way they have gained some new skilled employees.

However, the industry has grown a lot in the last 20 years in Estonia.

Alise Technic has many good partners in Pärnu and in other parts of Estonia, since it is a small country. Mainly surface treatment, e.g. painting and grinding, is outsourced from other companies. In Pärnu there is also a strong community thinking: everyone tries to help each other and create work and welfare for the whole city and region.

Versatile subcontracting

Alise Technic currently has around 30 customers of which 12 are main customers, for whom they work almost every day. Details for building sector, automation, machinery, car building, furniture, medical sector, and electronics.

Most of the parts they produce are going to Latvia, to a Swedish-owned international company, which then exports the finished products all over the world.

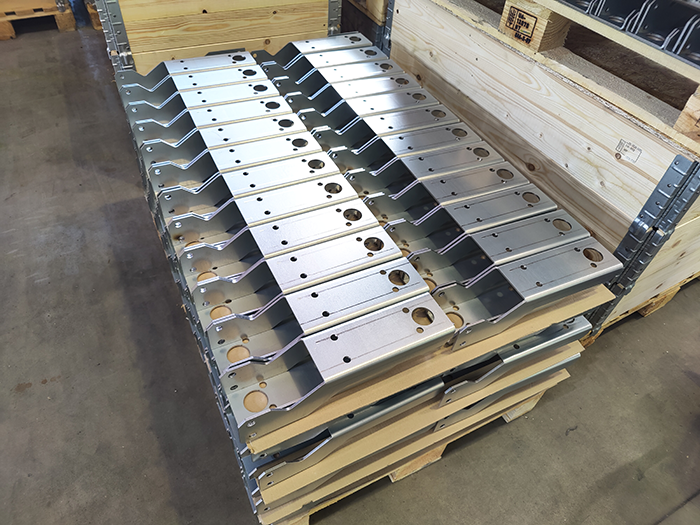

The company does prototyping, and small and big batches (from 5 to 3000 pcs). 200-300 pcs is the most common batch size to produce. Despite of the stable customer-base, manufacturing is order-based, since parts are changing so quickly, and it is not ecological to produce in stock. The company has certificates for Sustainability and Environment, which are important values in their everyday work. Customers also require sustainability more and more.

"We work with many different materials, between 0.5–20 mm in thickness, but the main thickness varies between 0.5–6 mm. We do small and big parts, and bigger assemblies too. Materials vary between aluminium, mild steel, stainless steel, copper, zinc-coated and painted materials, and even technical plastics." explains the Production manager Danel Tammeleht.

New customers are always welcome, big and small. And as the city of Pärnu and the whole country are small, you need to have good relationships with all your “neighbours”. The company also has a principal of not to say no to local needs.

Alise Technic does not have own products – at least not yet. That would require time to plan, design, and manufacture - and a good idea. Energy and medical sectors could be areas where they would like to involve also with their own products.

Promise to customers

Alise Technic’s future aims for more automation of the production and growth of the company. Automation is a must, since there are difficulties in getting skilled staff, and automation also helps in stabilising the production. The company finished an enlargement in their production facilities in 2023 and has now more capacity in serving their customers.

The growth needs to be executed in a way that quality stays on a high level and promises to customers can be kept. The company also has a reputation of good competence and flexibility, which are important values for the company.

Design work for customers has been reduced, while it is not profitable enough. Customers don’t usually want to pay extra for it.

As a subcontracting company, Alise is not doing a lot of marketing. They have been participating in some exhibitions but the best way to get new customers is that they hear about Alise Technic from other companies. The company also uses sales agents in Finland and Germany, which is the best way to get customers from abroad.

CO-OPERATION WITH PRIMA POWER

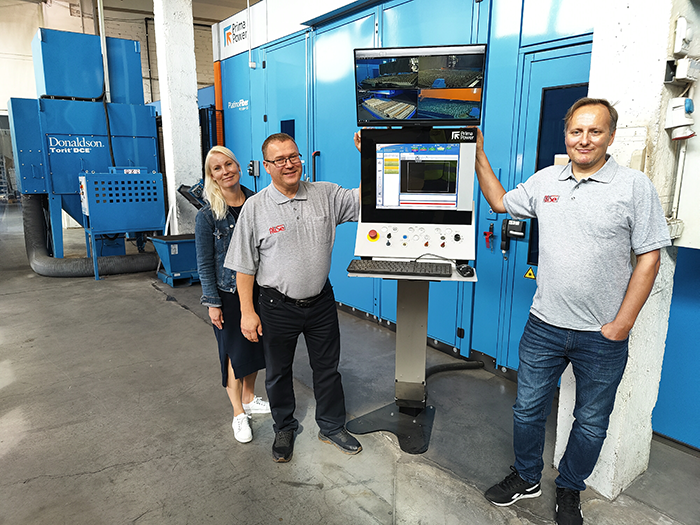

The company currently has five Prima Power machines: an F6 punching machine (1999; the 1st machine bought as second-hand in 2005 from Germany), a LPe6 punch-laser combination machine (2012), a servo-electric press brake (2013), and a Platino 2D laser cutting machine with a Night Train storage (2021).

The latest, and fifth Prima Power machine purchased, is an automatic panel bender EBe 3320 with a lot of options. This investment was done in 2024, and the panel bender was connected to the existing Night Train storage system. So, the cooperation continues, and the automated flexible manufacturing system of the company is growing and enabling more versatile manufacturing and subcontracting.

The good professional service is one reason why Alise Technic has kept on investing in Prima Power machines. The service has a will to solve the problems of the customer. Also, Prima Power Finland factory is near so the local service can always get help from the specialists there. Alise Technic has been the first company in Estonia to invest in some of the latest technology of Prima Power.

The best Prima Power investment is difficult to name, since all the machines have helped the company to grow and have enabled them to gain new customers. The combined punch-laser machine has opened more doors to new production, as it is not a common machine in the Estonian market. Maybe the big investment with Night Train storage has been the best, because it has started a new era in automating their manufacturing.

In future, Alise Technic wants to increase the level of automation in their production. They predict that the main growth can be seen in the energy and medical sectors.

Ищете аналогичное решение для своей компании? Найдите его здесь

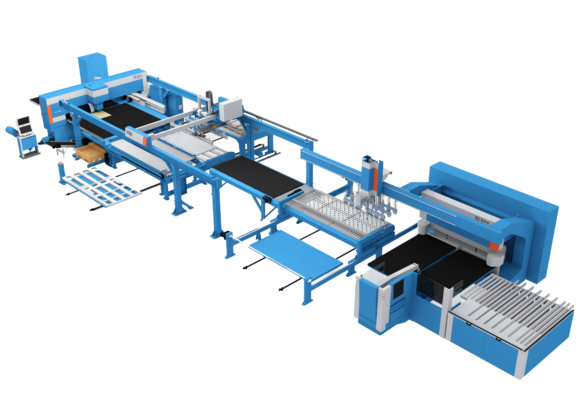

Линия LPBB

ГИБКИЕ ПРОИЗВОДСТВЕННЫЕ СИСТЕМЫ

Искусство интеграции

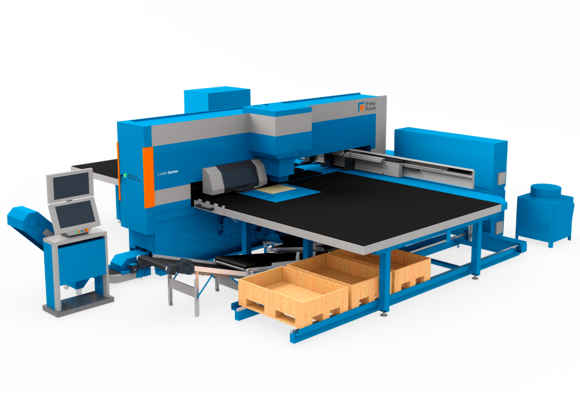

Комбинированный пробивной пресс с лазером Combi Genius

КОМБИНИРОВАННЫЕ ПРОБИВНЫЕ/ЛАЗЕРНЫЕ СТАНКИ

Штамповка + Лазерная Резка = Экономия производственных ресурсов

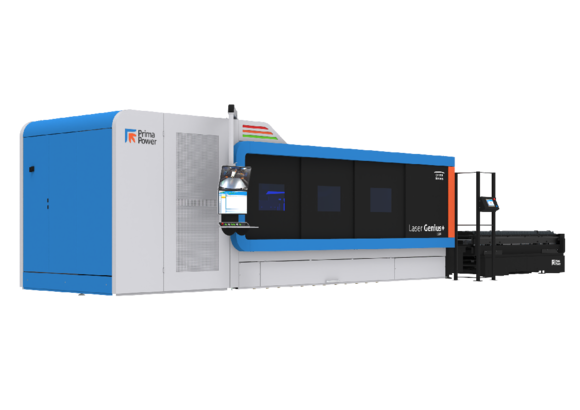

Laser Genius+

УСТАНОВКИ 2D ЛАЗЕРНОЙ РЕЗКИ