Epta Gruppo - Gaining competitiveness through automation

How epta gruppo’s partnership with prima power is driving its industrialization and growth

How epta gruppo’s partnership with prima power is driving its industrialization and growth

The Italian Group has integrated Prima Power machinery to streamline its manufacturing flow, significantly enhancing competitiveness and customer satisfaction.

EPTA’s success arises from its commitment to innovation, exemplified by its partnership with Prima Power. The PSBB line boosts sheet metal processing, highlighting EPTA’s role in enhancing production efficiency and flexibility for varied customer needs.

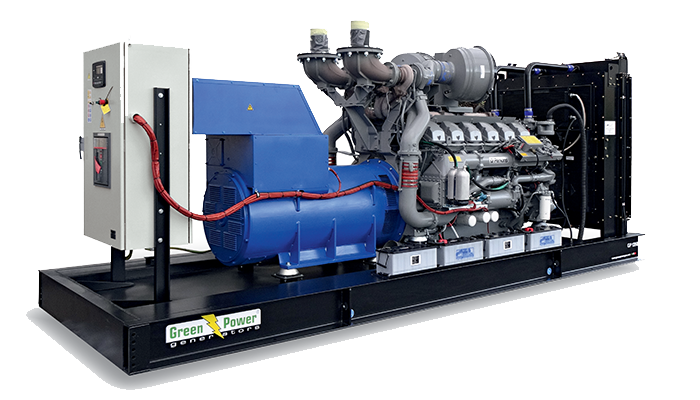

EPTA, meaning ‘seven’ in Greek, refers to the number of founding partners. Now a colossus with an annual turnover of over 250 million, EPTA was born in the late 1980s from the Brugnettini family’s entrepreneurial vision. They founded Idrofoglia, specializing in irrigation systems, motor pumps, and fire-fighting units. “As time passed,” says Alberto Brugnettini, managing director at Green Power Systems, “we realized that relying on a single market was risky, so we expanded our expertise into new sectors. This led to the establishment of Green Power Systems, specializing in the production of generators; Modula, focused on the thermoforming of plastic materials; and other companies in the early 1990s, which are now unified under the EPTA Gruppo umbrella.”

“Green Power Systems has 150 employees, with 100 in production”, Brugnettini adds. “Our strength lies in our extensive sales network and ability to provide off-list products. Our core value is responsiveness to customer requests. This has led us to expand into standby, agriculture, oil and gas, residential, and other sectors, enhancing our customer satisfaction and competitiveness.”

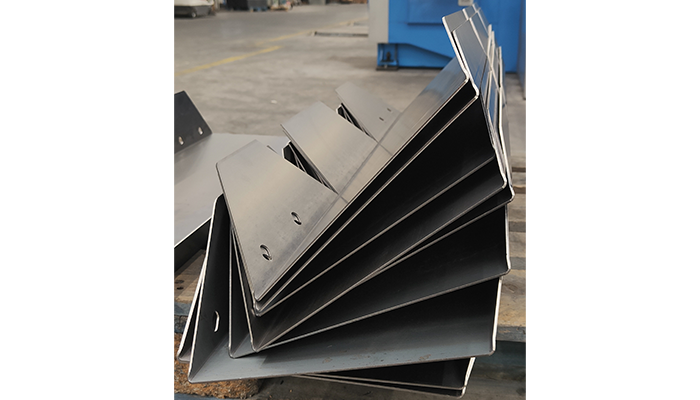

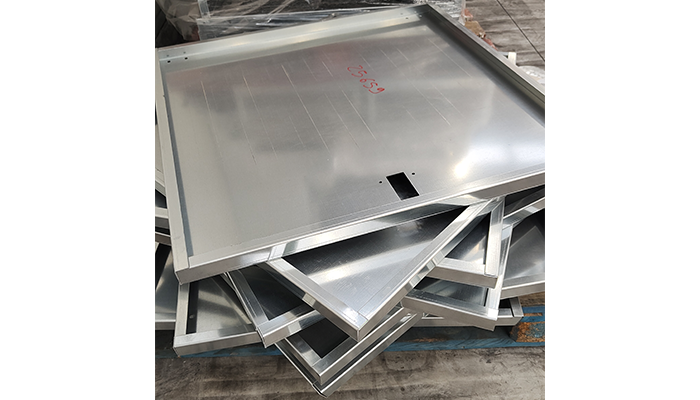

Idrofoglia, another Group company where sheet metal machining is key, attributes this success to EPTA’s philosophy, based on two key principles: internalizing most processing and flexible production for both large batches and customized needs.

IN-HOUSE PRODUCTION WHEREVER POSSIBLE

Green Power and Idrofoglia have largely internalized their machining operations. In-house production allows to meet customer requests promptly, avoiding reliance on third-party schedules.

EPTA has allocated about 20,000 square meters at the Lunano (PU) plant for carpentry, despite different production needs between Idrofoglia and Green Power. The Group carefully selects suppliers who align with their values of customer focus, innovation, and in-house production.

“We’ve worked with Prima Power for many years,” says Manuel Polverini, EPTA Gruppo production manager. “Their cutting and forming technology has been crucial in our growth and flexibility, enabling us to become the leading company we are today. We value their continuous innovation and ability to listen to our needs.”

A PARTNERSHIP WITH SHARED VALUES

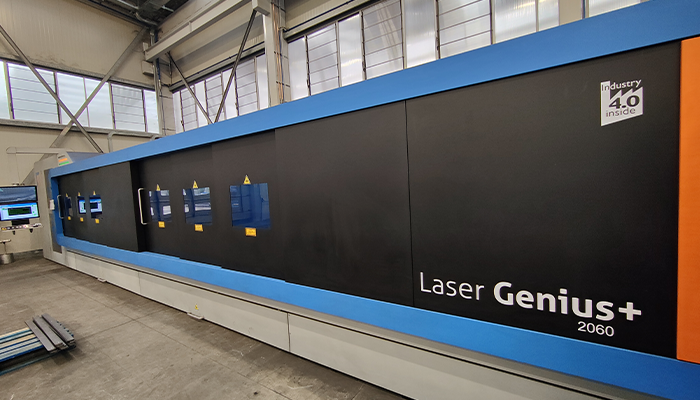

In the EPTA carpentry area, the Laser Genius+ 2060 laser cutting system with a 10-kW fiber source and the PSBB automated production line are used. The Laser Genius+ 2060, ideal for Idrofoglia’s thicker materials, offers high speed and precision, processing up to 30 mm of steel with a repeatability of 0.03 mm.

The PSBB line, central to EPTA’s industrialization efforts, integrates a Shear Genius SG 1540 punching and shearing unit with an Express Bender EBe 3320 panel bender, supported by a sheet metal storage and a PSR robot. This setup automates the production of punched and bent panels and offers flexibility, allowing machinery to operate in series or feed semi-finished products.

“The PSBB line not only overcomes production obstacles but optimizes material flow and improves batch management and delivery times”, Polverini adds. “The laser offers flexibility, and adding the punching machine and PSR has significantly increased productivity and industrialized our processes.”

Polverini concludes, “The PSBB line has also redefined our approach to custom products, enabling us to produce standard components and assemble them in order to meet customization needs.”

USER-FRIENDLY AND GREEN TECHNOLOGIES

The Pesaro-based Group values Prima Power’s machinery for its performance, efficiency, and ease of use. Polverini notes, “New technologies have alleviated operators’ tasks a lot. Prima Power machines automate adjustments, making it easier for less experienced operators to carry out important work.”

The Group also appreciates Prima Power’s focus on sustainability. “Our goal is to minimize environmental impact. Prima Power’s low-consumption, fully electric machines support this, and their just-in-time production reduces storage needs and CO2 emissions”, Polverini states.

THE FUTURE REQUIRES EVEN MORE “POWER”

EPTA has achieved notable success in over 120 countries, especially in Italy, Europe, and Africa, due to diverse sectors served, high customer responsiveness, and efficient production. “We aim to grow by consolidating current customers and expanding into markets with opportunities like hybrid generators and renewable energy applications”, Brugnettini adds.

A new 35,000-square-meter hub will house Green Power Systems’ production, doubling turnover and workforce, while Idrofoglia will use the Lunano plant.

“To increase production, we’ll likely need new technologies”, Polverini concludes. “I’m confident Prima Power will be our preferred supplier due to their consistent support and optimal tools.”

UNPARALLELED FLEXIBILITY WITH THE PSBB LINE

The PSBB line integrates punching, shearing, buffering, and panel bending, revolutionizing the way sheet metal is processed. It optimizes material flow for efficient, uninterrupted production, balancing time and cost. The servo-electric functions and sophisticated software enhance productivity with unmanned operation, faster production, and zero set-up time. Seamless data transfer ensures transparency. The PSBB line can be paired with Prima Power’s automation solutions, like the PSR robot, sorting systems, automatic loaders, and the Night Train FMS for superior performance.

Опыт в области

интеграции

Клиентоориенти

рованный подход

Высокоскоро

стные гибкие решения

Наш подход к устойчивому развитию: уменьшение нашего воздействия на планету также имеет экономические последствия.

Мы работаем по всему миру: найдите ближайшее к вам представительство Prima Power и свяжитесь с нами.

© PRIMA INDUSTRIE S.p.A., single-member company | Via Torino-Pianezza, 36 - 10093 COLLEGNO (TO) ITALIA | Share Capital €26.208.185 | VAT 03736080015 - C.C.I.A.A. Torino 582421 | Reg. Impr. Torino n. 03736080015