Reshoring manufacturing jobs is a key goal for boosting North American industry. Although it’s challenging and not guaranteed, with proper investment in technology and planning, success is possible. Proslat, based in Valleyfield, Quebec, is a prime example of this success.

Proslat, founded in 2010, manufactures garage organization systems like slatwall panels, overhead racks, storage lifts, cabinets, and tool chests. Initially, they outsourced manufacturing to China but now handle it in North America. “In 2017, we didn’t have the volume to justify local manufacturing,” said founder Eric Letham. “Even now, it’s a gamble, but I knew it was worth trying.”

Letham identified an opportunity: “Chinese products vary in quality, and our North American competitors are not as automated as they could be.” He aims to offer a competitive yet more affordable alternative. “Our competitors make 80 cabinet boxes a week with 30 employees; we make 80 a day with 7. Yes, we had to invest in technology, and yes, it will always need maintenance. But the efficiency we have is second to none.”

Optimizing production with automated cutting and bending

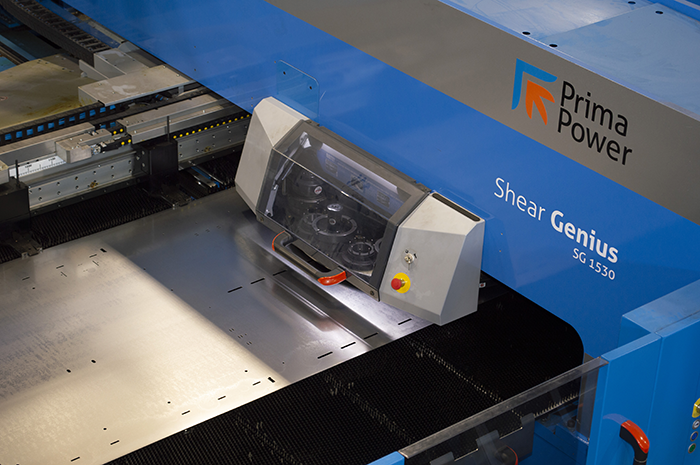

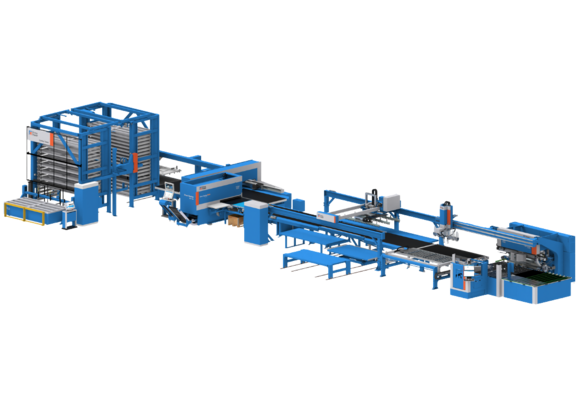

At Proslat, manufacturing begins with the Prima Power PSBB line, which automatically turns blank sheets into high-quality, bent components. The system’s flexible material flow optimizes manufacturing costs and throughput. For smaller parts, Proslat uses a Prima Power eP 0520 electric press brake. After cutting, punching, and bending, parts are welded and sent to the paint booth, primarily using 20 to 14 ga. cold-rolled steel and 16 ga. stainless steel.

“Prima Power’s equipment is essential for us, converting sheet metal to finished parts swiftly,” Letham said. “One person handles the shear, punch, and bend processes while another manages the press brake, welding, and painting. We achieve a fully welded and painted cabinet box with just two or three people. Speed is key; Manufacturing leaders know that day shifts are the most profitable, and night shifts are less efficient. We plan to shift from four 10-hour shifts to three 12-hour shifts to improve work-life balance.”

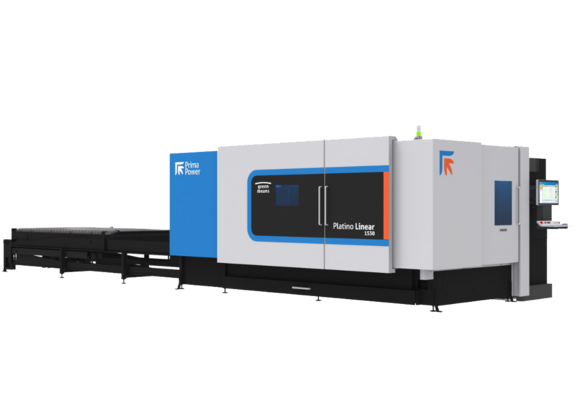

Proslat runs the PSBB unmanned overnight for large orders, monitored via cameras. However, some parts are too small for the PSBB, so Proslat has invested in a new Prima Power Platino Linear, a highly productive and compact 2D Laser with load-unload capabilities. “The laser will help with parts the PSBB struggles with and will significantly boost our production speed,” Letham added.

Achieving a balanced production flow

Letham aims to set realistic production targets with the current team size. “I want to be able to tell my team, ‘This week, the steel budget is 100,000 lbs. Hit that target, and everyone gets a bonus,’” Letham said. “A smaller team is more flexible but must pivot quickly without losing quality.”

Proslat’s compact production line moves parts from the PSBB or press brake via conveyor to a nearby weld cell, then to the paint booth, and finally to an assembly conveyor at a comfortable height for workers.

“Adding technology to a tight line is challenging, but we’ve made space for it,” Letham noted. “For instance, we used to rivet drawers, but it was slow and problematic. Now, the PSBB bends a drawer in about 35 seconds, and the welder takes about 40 seconds, removing a previous bottleneck. Small time differences can create backups, but we balance this with efficient shell runs.”