Flama | Servo-electric technology driving efficiency and global growth

THANKS TO A LONG-STANDING AND SUCCESSFUL COLLABORATION WITH PRIMA POWER, SUBCONTRACTOR FLAMA HAS NOT ONLY MANAGED TO STAY ABREAST OF THE TIMES, BUT ALSO TO EXPAND ITS REACH BRILLIANTLY ACROSS NATIONAL BORDERS. ITS STRENGTH LIES IN BOTH ITS CLOSE-KNIT AND ENTERPRISING WORKFORCE AND ITS IMPRESSIVE FLEET OF MACHINERY, WHICH RIVALS THAT OF MUCH MORE STRUCTURED COMPANIES

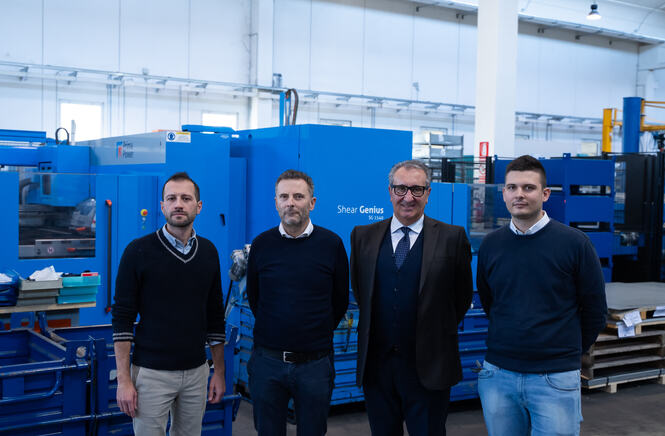

Working with large foreign industrial groups is not easy. It's often not just about having the best offer, but also about meeting audits and minimum size or turnover requirements. Rarely do such groups grant exemptions, preferring to work with smaller companies as well, but such exemptions do occur if the company proves to have exceptional characteristics beyond the required standards. One such company is Flama, based in Castelnuovo del Garda in the province of Verona, which operates in subcontracting supplies of small to medium thickness sheet metal components.

While collaboration with large foreign industrial groups is Flama's present, the past was something else entirely. In 1995, the current owner Massimiliano Zonaro, with many years of experience in the production of paint technologies, decided to go into business for himself with his brother. "We spent the first few years making gates and railings," says the owner, "but we had a lot of passion and desire to compete, so in 1998 we started working with sheet metal and bought our first piece of equipment: a press brake and a laser cutting system. The products were almost exclusively for the company I had previously worked for, and although this allowed us to grow, we were in danger of becoming a one-customer company with all the risks that entails, so in 2002 we decided to focus purely on subcontracting and broadening our customer base."

This decision proved to be a success for Flama, allowing the company to continue growing, both in terms of turnover and staff, with the construction of a new warehouse; after overcoming the crisis of 2008 with some difficulty, the company continued to grow, establishing itself purely as a subcontractor able to serve both large companies and even smaller ones. "The second turning point in our history," said Mr Zonaro, "were the years 2014-2019. During this time, we underwent a transformation from what was then a typical owner-managed business to a truly modern company with a management structure that was not dependent on a single senior figure. With the help of these new recruits, we also decided to streamline our customer portfolio to focus on those whose business volume and level of technology would provide a springboard for future growth."

This strategy has also enabled the company to move from a strictly executive role to a more consultative one, assisting customers step by step right from the design phase and taking on the role of main contractor for major projects; this approach has been appreciated by Italian customers, but even more so by foreign companies, and it has been the real driving force behind the company's internationalization. "To date, 30% of our turnover comes from customers outside Italy," says Luca Zonaro, Sales Manager and second generation in the company, "and we want to increase this percentage in the future. Working with this type of company came about thanks to our know-how, but also as a result of the level of technology we have reached: our aim has always been to have the best technologies at our disposal, all supported by automated systems, and this has been particularly appreciated by foreign industries which, having seen that we are structured the same way as much larger companies, have placed orders with us even though we might not have been large enough to be part of their supplier base."

Flama's real hallmark then, is its technology and approach, and part of the credit for that goes to Prima Power, which currently supplies the company with some stand-alone machines and a flexible manufacturing system that includes a combined punching-shearing machine and a laser cutting system.

A historic collaboration for cutting...

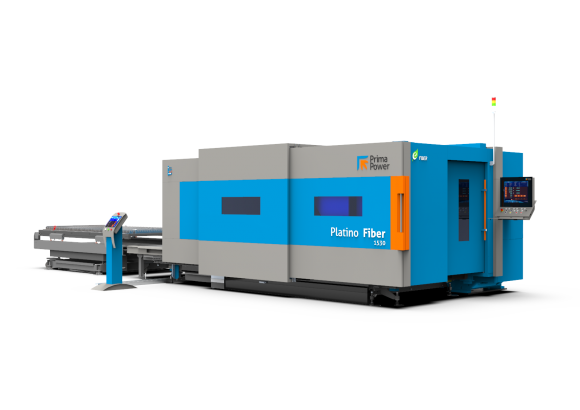

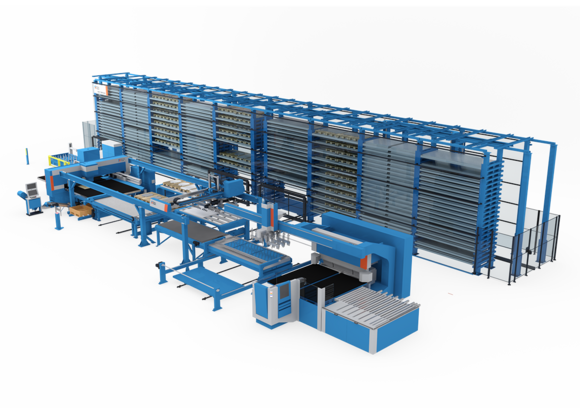

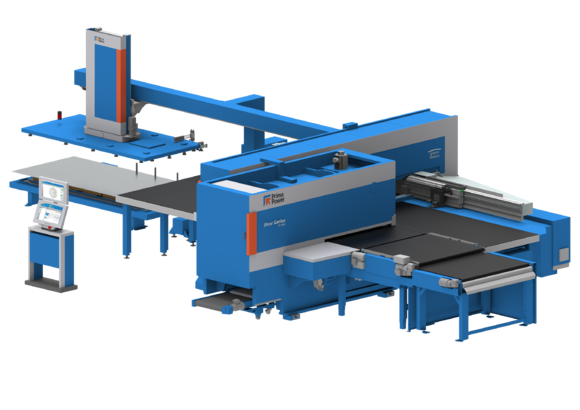

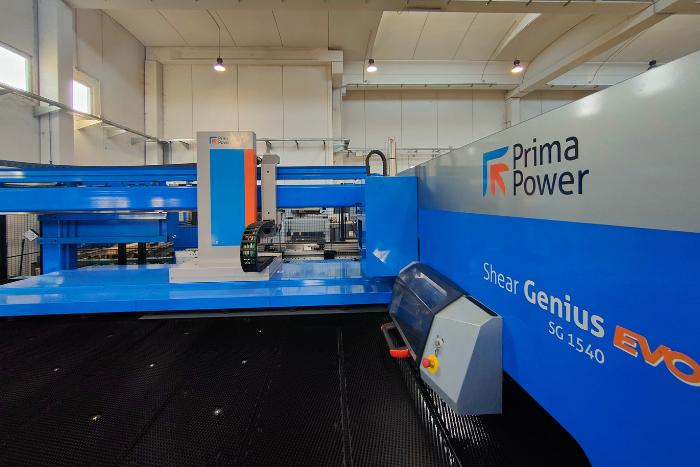

“The synergy with Prima Power was formed even before Flama,” says the owner. “During my previous work experience, I had the pleasure of seeing a combined punching and angle shearing machine of this brand in operation, which was futuristic at the time, as it was connected to the warehouse and allowed a much higher productivity compared to solutions of that period; so, when we needed to equip ourselves with sheet metal working technology at Flama, the choice was natural and, in hindsight, all I can say is that it was a far-sighted decision.” Today, Flama has several Prima Power machines for cutting and bending sheet metal, either in a stand-alone configuration or integrated into a flexible manufacturing system. The company's flagship product is the Night Train flexible manufacturing system, to which a Shear Genius punching-shearing machine and a 4 kW Platino Fiber laser cutting machine are connected.

“The Night Train automated storage solution,” says Gianni Boldrin, Production Manager, “is the production heart of the cutting department; it gives us maximum flexibility, allowing us to handle both small and large orders on the same day, thanks to the possibility of feeding the machines with different thicknesses and materials at any given time; this is fundamental for anyone like us, whose planning is based on orders and not on types of material.”

The Night Train features a Platino Fiber 1530 laser machine and one of the company's two integrated Shear Genius punching-shearing machines. The former aims to ensure high productivity with reduced cycle times, increased process reliability and efficient energy consumption. This means low environmental impact and considerable flexibility in terms of thickness and materials that can be processed. The structure of the Platino Fiber, with its synthetic granite frame and die-cast aluminum cantilever structure, guarantees precision and robustness, as well as unprecedented access to the work area. The cutting head designed by Prima Power, with a single focusing lens and integrated safety glass, adapts to all production requirements and, thanks to the use of a 4 kW power source, it can also process highly reflective materials. The CNC, operator interface and programming software, all developed by the Collegno-based company, provide an intelligent and intuitive user experience.

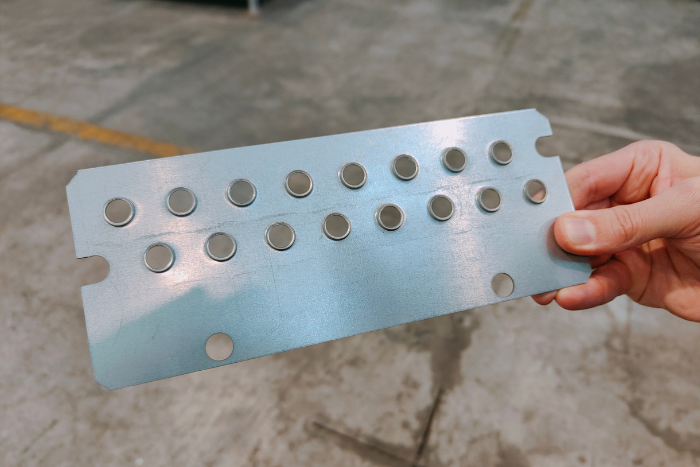

"Laser cutting gives us great productivity," continues Mr Boldrin, "but it is the Shear Genius combi machines that give us the most expertise. Thanks to the potential of servo-electric punching, we can perform deep-drawing, threading or countersinking operations directly on the machine, thus eliminating all handling and rework waste. Furthermore, Prima Power machines are equipped with a tool for engraving the protective PVC on sheet metal, thus facilitating welding operations without having to manually remove the entire protective layer, which keeps its function on parts not affected by the joint. This significantly improves the quality of the finished product."

... and for bending

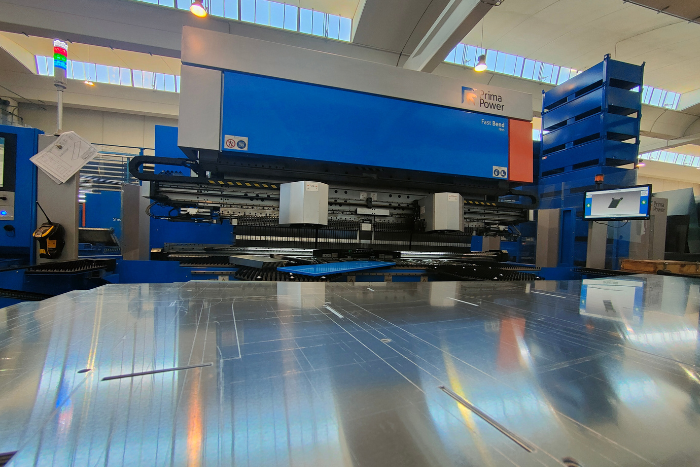

If productivity, automation and flexibility are the hallmarks of Flama's cutting technologies, speed, precision and ease of use are the hallmarks of its bending machines. For bending, there are two eP series press brakes and a Fast Bend semi-automatic panel bender.

The former are servo-electric press brakes designed to maximize performance on low to medium thicknesses. Like all Prima Power technologies, the eP series press brakes are distinguished by their innovative approach, known as "Green means®", which reflects the brand's (and therefore Flama's) commitment to environmental sustainability, efficiency and high productivity. This philosophy translates into tangible benefits such as greater operational versatility, lower energy consumption, reduced maintenance and oil disposal operations, thus contributing to an overall more sustainable production process. The eP press brakes feature superior acceleration and deceleration, along with the fast response of the servo-electric drive system; this not only allows a significant increase in productivity, reducing cycle times by up to 30%, but also ensures a programmable working speed that does not compromise product quality or operator safety, thanks to the Lazer Safe IRIS system. "The strengths of the eP series," explains the owner, "lie in its energy efficiency, which reduces the overall environmental footprint; in its high productivity, thanks to shorter cycle times and greater process reliability; and in its modularity, which allows us to quickly adapt to different production requirements."

As for the Fast Bend panel bender, this is an advanced solution for semi-automatic bending that sits somewhere between a traditional press brake and an automatic panel bender, combining the efficiency of an automatic bending sequence with a manual loading, turning and unloading interface. The Fast Bend allows complex processing, including quick changes between positive and negative bends, flattened and radius bends, with exceptional accuracy thanks to the angle correction database and servo-electric technology. One particular innovation is the manipulator, equipped with a suction cup feeder, which is superior to the systems used on traditional panel bending machines and increases the range of products that can be bent. This feature ensures a quick and efficient response to the need to reduce the number of parts in the production batch, while maintaining ease of use and a lower overall cost than a fully automated solution.

"The features of Fast Bend that have satisfied us the most so far," continues Mr Zonaro, "are the superb bend quality that the angle correction and servo-electric technology provide, the flexibility and ease of use for the operator thanks to the 3D programming, the integrated simulation of the bending cycle and the barcode reader that allows easy recall of the machining programs."

Efficient production requires more than just powerful machines; performance is maximized by management that is both integrated and, wherever possible, digital. It is in this respect too that Flama is at the cutting edge of technology, as the flexible production system, the Platino Fiber laser, the two Shear Geniuses and the panel bender are programmed directly by the technical department, thus exploiting the full potential of Prima Power's "4.0 ready" technologies.

Leading the way on ESG

Flama's successful business strategy, backed by state-of-the-art machinery, has allowed the company to double its turnover from 5 to 10 million euros, becoming a reference point for the subcontracting of medium-thickness sheet metal, with particular expertise in prepainted, galvanized and aluminized sheet metal, stainless steel and aluminum; although the company is open to collaborating in all sectors where sheet metal components are used, its strong expertise in paneling and punching has given it particular specialization in the intralogistics, HVAC, food, packaging and automotive sectors.

These results are achieved in full compliance with sustainability guidelines: "We believe in a sustainable industry, as opposed to the stereotype of factories as pollution-intensive places," says Mr Zonaro. "Suffice it to say that we are able to meet 70% of our energy needs with our 250 kW photovoltaic system, and we also have our own nitrogen generators so we don't have to source externally. Sustainability is also reflected in our daily production choices: in fact, whenever possible, we tend to favor servo-electric punching with Shear Genius combos because it is a less energy-intensive production technique, both in terms of absorbed power and consumables."

Environmental sustainability is only one of the pillars of Flama's ESG manifesto; another, of paramount importance, is the social aspect, highlighted by the relationship with its 50 employees. "Those who work in manufacturing are well aware that a quality technician is rare," the owner continues, "so once you find willing and properly trained employees, you want to keep them. That’s why at Flama we try to create a working environment that is as welcoming as possible: firstly, we take great care of the aesthetics, looking after both the offices and the production area so that everything is always clean and tidy; secondly, we equip ourselves with technology that is as automated as possible, in order to relieve our technicians of all repetitive tasks and give them the opportunity to discover the full potential of the machines; and lastly, we offer our employees many benefits."

We’ve told you all about Flama's evolution up to this point and its transition, partly thanks to Prima Power's technological support, from artisan production to a 4.0 factory with a clear international vocation; but, just like its relationship with Prima Power, its journey is not destined to end here: "In the near future, we intend to increase our presence in foreign markets," says the owner, "because we have noticed that a great impetus for our growth comes from working with these companies. This project is also driving us to be as comprehensive as possible in terms of the fleet, both by upgrading existing equipment and by introducing new technologies, and in this respect we know that we are well taken care of."

The second turning point in our history were the years 2014–2019. During this time, we transformed from a typical owner-managed business into a truly modern company, with a management structure that no longer depends on a single senior figure.

Are you looking for a similar solution for your company? Find it here

Platino Fiber

CORTE A LASER 2D

Rentável para uma mistura de produção que inclui todos os materiais e espessuras

Night Train FMS®

ELASTYCZNE SYSTEMY PRODUKCYJNE FMS

Wiodące technologicznie rozwiązanie w zakresie magazynowania w zautomatyzowanych systemach elastycznej produkcji

Shear Genius

MASZYNY KOMBI DO WYKRAWANIA I CIĘCIA GILOTYNĄ

Najwyższa wydajność przy integracji wykrawania i cięcia gilotyną

eP Series

SERWOELEKTRYCZNE PRASY KRAWĘDZIOWE

Wysoka niezawodność i maksymalna wydajność

FBe Fast Bend

GIĘTARKI DO BLACH