Automation, Prática’s recipe for innovation

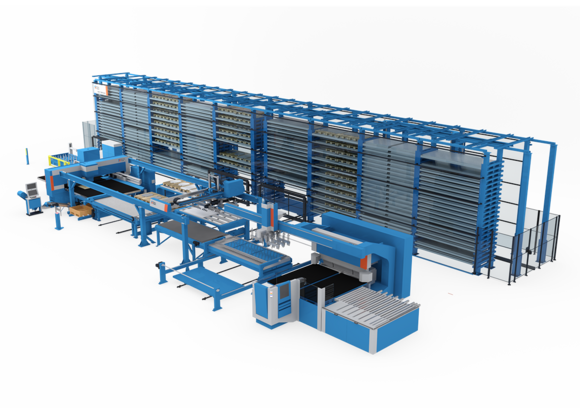

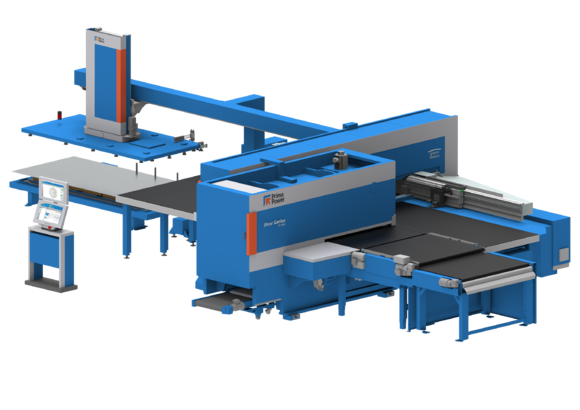

“By establishing a productive and profitable partnership with Prima Power, Prática propelled its manufacturing process into a new era, characterized by advanced automation”, explained Luiz. With increased sales and plans to automate the entire factory process, in 2012 Prática sold its entry-level machines and geared up for the next level of productivity. Collaborating with the Prima Power technical and sales team, Prática further enhanced its processes with automations. The company successfully installed the Night Train FMS along with the fully automated FBe Bending Center, the LPe (Laser Punch Combi), and a Shear Genius. This fully-automated system was the first of its kind for the Brazilian market. According to Luiz: “The adoption of the Prima Power Night Train FMS was a breakthrough success in production speed, advanced storage control, employee safety, and process modernization.”

These decisive investments allowed the company to establish dominance in the market with its robust line of innovative ovens for the industrial and bakery sectors. The expansion propelled Prática onto the global stage, opening subsidiaries first in neighboring Chile and later in the flourishing United States.

Strengthening production with local service support

Prática has set up a local technical assistance and maintenance agreement focusing on preventive maintenance. By regularly collaborating with local Prima Power technical support, they optimize spare part efficiency and address issues effectively. “Along with consistent data on production efficiency without material losses and rework costs, we appreciate the local service support,” adds Luiz.

Looking ahead: Prática’s plans for growth

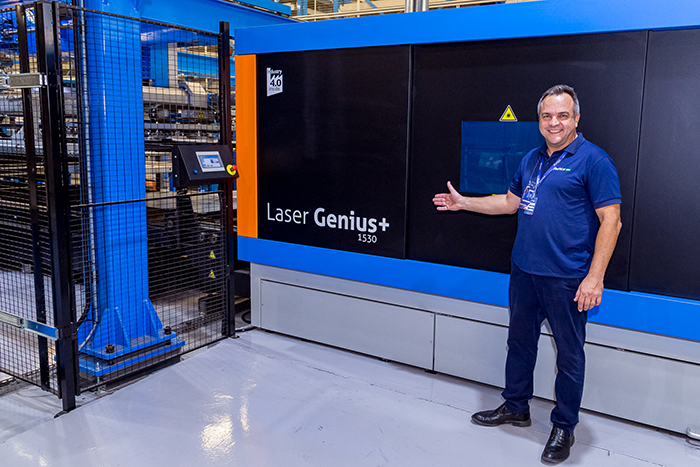

Today, Prática champions its capabilities not only through modular upgrades to their manufacturing line but also by sharing the productivity benefits of Prima Power equipment with other Brazilian manufacturers. In 2023, Prática advanced further by investing in multiple upgrades to its manufacturing line. “By upgrading the original Night Train’s hardware and software, we gained additional raw material capacity, finished or semi-finished part buffering space, and enhanced material handling for the updated production flow”, points out Luiz. In late 2023, Prática showcased its dedication and partnership with Prima Power South America by hosting an Open House at its flagship factory. Luiz spent the day with the Prima Power team and prospective clients, demonstrating how the equipment enhanced operations. Through plant tours, discussion sessions lead by Edgar Carvalho, Pratica’s Printing supervisor, and a live look at process efficiencies, it was clear that Prática and Prima Power are a recipe for productivity. Luiz highlighted the newest equipment addition, The Laser Genius+, discussing its speed, enhanced automation, and how its quality supports the final product’s assembly. The roster of Prima Power assets at Prática continues to expand its capabilities and output. In addition to showcasing the new laser, Prática’s Industrial Director, Douglas Vale, demonstrated their two new servo-electric press brakes for larger parts. The fully servo-electric eP brakes are efficient and have low energy consumption, fully aligned with Prática’s commitment to environmentally conscious processes. Prática is a modern model for forward-thinking manufacturers, showcasing pride in Brazilian manufacturing with sophisticated and efficient industrial kitchen products. Guided by strong values, a steadfast commitment, and the mission to help clients prepare quality food without waste.