Prima Power at FABTECH Chicago 2023

Come visit us at our Booth A2145 from September 11-14, 2023 at McCormick Place in Chicago, Illinois

The machines available at our booth

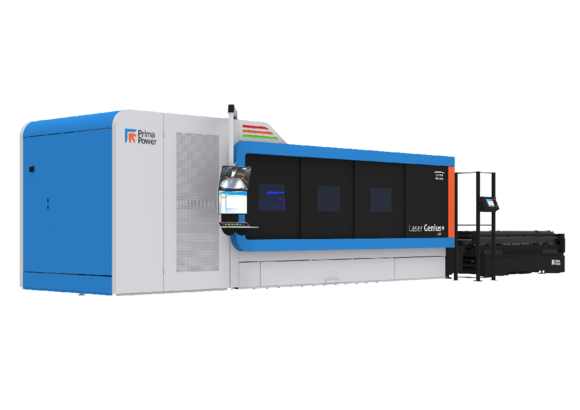

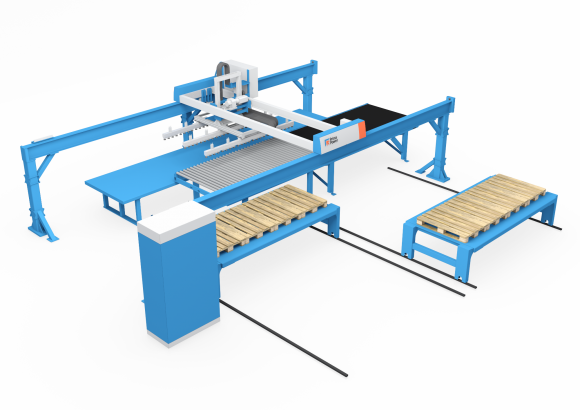

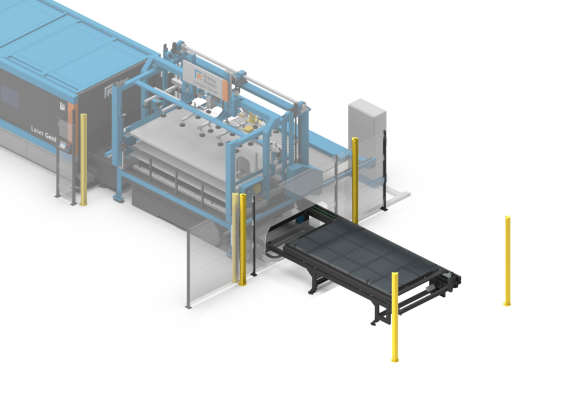

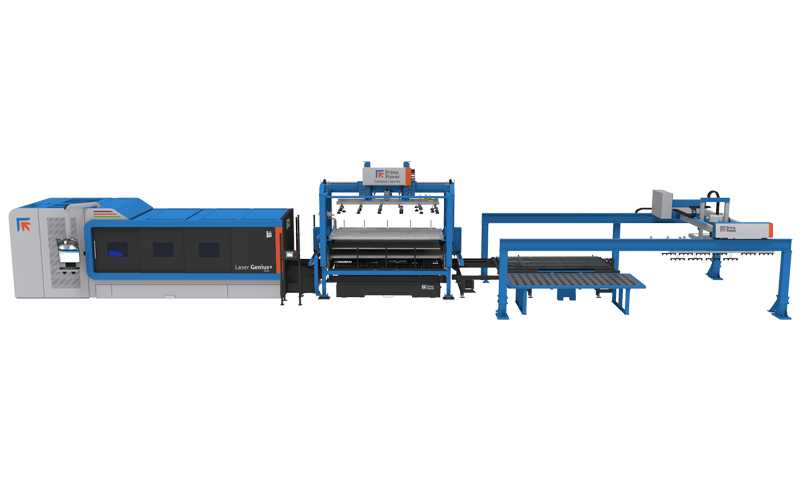

Laser Genius+ with compact server, PSR, 3rd pallet

Short cycle times and a wide range of integration possibilities with automation modules and bending technology.

At FABTECH, the machine will be showcased with the 2-shelf Compact Server automatic loading and unloading device for both raw and processed sheets and an additional loading/unloading station. This configuration is also including the PSR 2D, an intelligent and flexible picking and stacking robot that provides high stacking accuracy and minimal stack spacing, automatically optimizing the use of the stacking area.

Thanks to the modular structure of the system and Prima Power's wide product portfolio, the PSR 2D can be directly connected to the Night Train FMS storage solution and an automatic panel bender, creating an automated production line from raw sheet metal to cut, and bent finished parts.

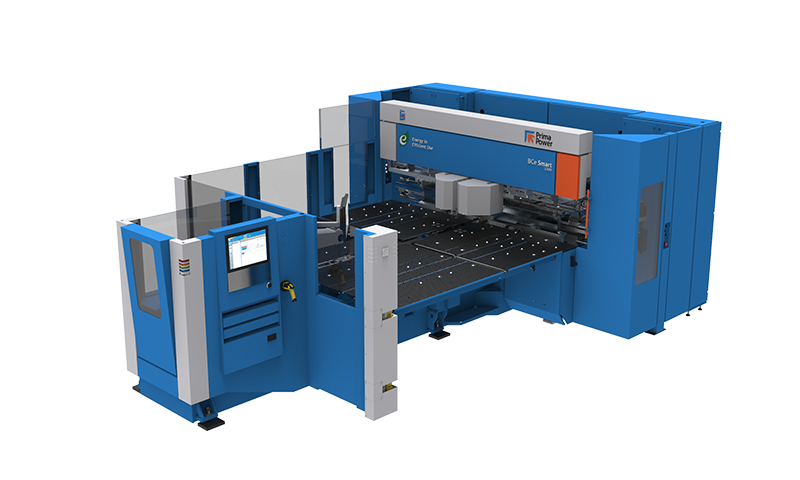

BCe Smart

The semi-automatic panel bender featuring the highly efficient servo-electric technology by Prima Power. Reliable and efficient productivity are achieved through simultaneous loading and unloading. The operator loads the blank metal sheet and unloads the bent component in a single sequence while the machine automates all the bending cycles to guarantee excellent bending quality thanks to its flexible bending capability. Maximum ergonomics and safety are achieved thanks to two laser scanners, instead of physical barriers, and worktable tops that can be lowered to facilitate the loading and unloading of small or medium-sized parts.

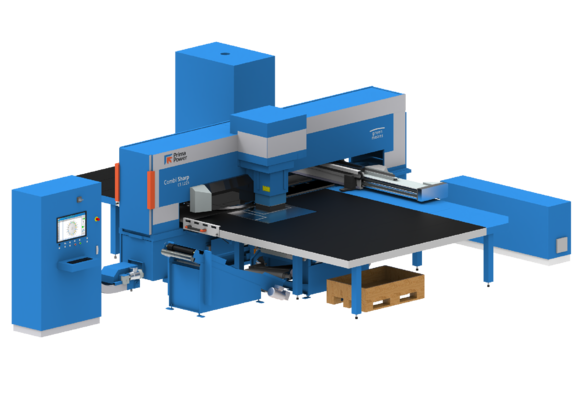

Combi Sharp

A compact, flexible and sustainable punching and fiber laser cutting cell with high accessibility.

With Combi Sharp, application flexibility is at its highest level: punching, forming, marking, bending, and laser cutting capabilities in one single manufacturing unit. By adding the Compact Express material loading and unloading device, the machine becomes an automated and efficient production cell with a very small footprint. With this device, material can be loaded and unloaded during machine operation, but manual loading and unloading operations are also still possible, as one side of the machine is open for the operator. Combi Sharp is a very versatile, multifunction tool for very different sheet metal product manufacturing up to 8 mm thickness and with the Compact Express automation, several different materials can be stored for different products and production batches.

Software

At Fabtech Chicago, we will be showcasing our latest software for sheet metal CAM and production management.

Suite of software products

Make your production process transparent and easy to manage.

- Starting from planning, monitoring, and controlling machine capacity up to controlling the entire production process from order management, to finished product and reporting.

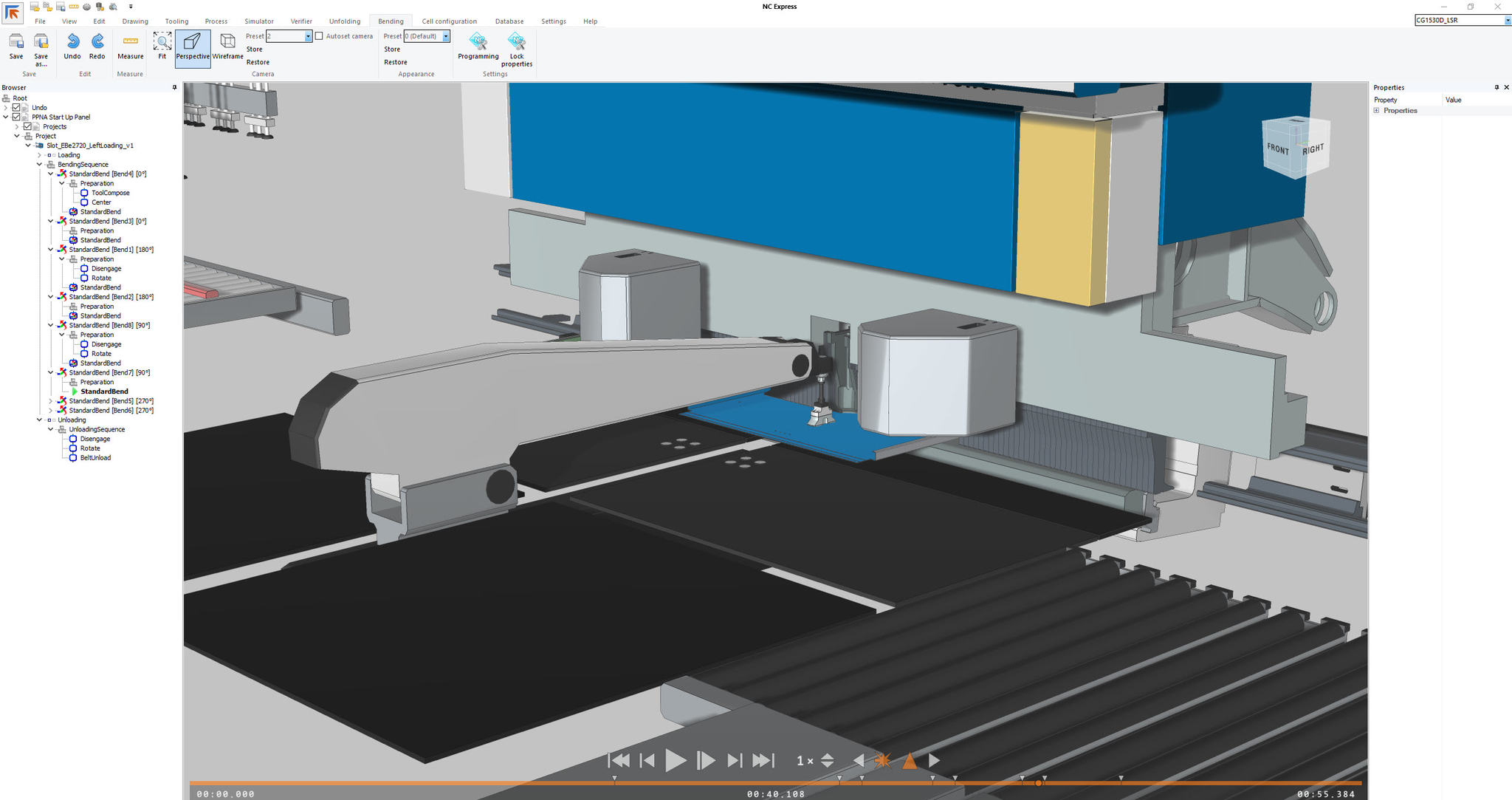

Master BendCam

- The complete 3D simulation of the bending process, which allows for a better optimization of the operations and a quick correction of possible mistakes during the off-line programming.

- The operator can add and remove machine tools through the interface to change the machine configuration

- Accurately calculate required time to process each part

Tulus® Analytics is the new online self-service portal that provides our customers with detailed information about their production and machines performances.