Prima Power in the Automotive sector

Find out what we do in the Automotive sector

Circular Economy, Automotive Industry Innovates to Zero emissions

Keen to grab a chunk of the huge addressable market for EVs, automakers will aim for economies of scale by building modular, scalable dedicated EV platform architectures.

With wastes generated by end-of-life vehicles becoming a massive problem, automotive companies will look beyond carbon-neutral factories to more fully embrace circular economy concepts and ideas of reuse and recycle. Propelled as much by their commitment to developing sustainable vehicles as by environmentally-friendly regulations the world over, the automotive industry will incorporate ‘Design and Dismantle’ principles at progressively earlier stages of the vehicle development process with the aim of reducing subsequent waste. (Source: Forbes 2021)

The automotive industry has radically changed in recent decades and our machines have also been developed and innovated accordingly. We have been forerunners of many trends, e.g. providing solutions suitable for cutting high-strength Hot Stamped Steel when the use of these materials was still only in its infancy.

In the automotive industry, the greatest challenges for intensive production are the drastic reduction of cycle times, maximum process reliability and efficient workflow management.

Sustainability, fuel savings and safety are key concepts in today's automotive manufacturing. The use of HSS materials points in this direction, making it possible to obtain light but very robust vehicles, with lower fuel consumption and emissions and greater safety for drivers and passengers.

In addition, our punch-laser combination machines are used in this sector for the high accuracy of the servo-electric punching device and the flexibility of the laser, capable of processing components of any shape.

The fibre laser can be very advantageous in the production of lightweight components, e.g. aluminium.

Experience

We have been serving the automotive sector since 1979.

Listening

We customise our machines to your actual needs.

Innovation

Our machines work to create high performance components, as required by the sector.

Solutions

Find your ideal solution

Our Laser Next family products are high-performance solutions for intensive automotive production:

- high dynamics and smart control techniques place it at the forefront in terms of productivity

- high-brightness fibre lasers and superior dynamics: maximum acceleration 2.1 g, maximum speed 208 m/min

- the best solutions in the management of positioning equipment for pieces and for loading/unloading operations with specially designed turntables

- Space saver thanks to the compact footprint. Easy and fast to install.

Our LaserNext 2141 is ideal for the cutting and welding large and components, since it has an even more spacious working volume.

Maximum flexibility guaranteed by multiple configurations:

- Two stations with split cabin and removable central wall

- Movable tables to simplify loading/unloading

- Turn table for intense production of large-size parts

Different solutions for material flow automation can be chosen to increase your productivity.

Our services cover all stages of the production cycle and grant maximum productivity.

All our systems are designed and developed based on the “Green Means concept”: they are productive and eco-sustainable at the same time.

Application examples

Behind each component is a Prima Power machine

- Vehicle hood

- Yellow goods cabin

- Large hydroformed components

- Large-size vehicle frame components

Browse our technologies to choose your machine

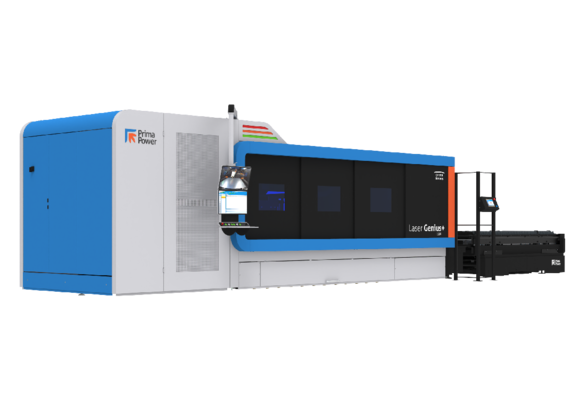

Laser Genius+

2D LASER CUTTING MACHINES

Prima Power laser machine faster, more precise, cheaper, for larger and heavier pieces.

Laser Next 2141

3D LASER CUTTING MACHINES

The flexible solution with large working envelope and best-in-class efficiency

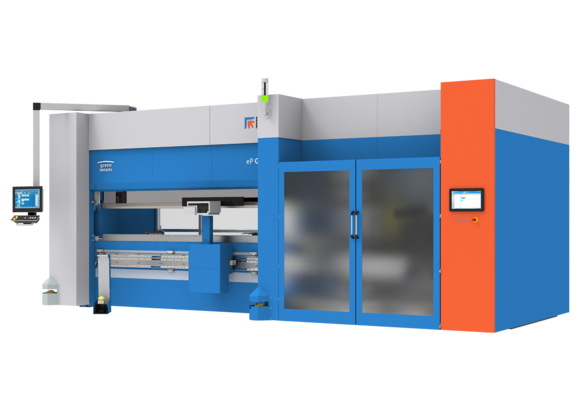

eP Genius

PRESS BRAKES

Efficient servo-electric bending solution with a fast and automatic tools change storage

STORIES OF EVOLUTION

Find out how a Prima Power machine took part in an Automotive company's success

Advanced Lasers Meet Diverse Needs of Tooling Group - Diversified Tooling

Advanced laser technology has been instrumental in making the four affiliated companies of the Diversified Tooling Group, Madison Heights, Mich., into a leading supplier of single-source manufacturing solutions to the automotive, heavy truck, defense, industrial equipment, power generation, rail, and foundry i

30+ Years of experience and still growing

Lasercraft USA Knows 5-Axis Laser Cutting Backed By 30 Years Experience And The Latest Technology -- Success Grows Using A Newly Acquired LASERDYNE® 430 With BeamDirector®

Top performance

With over a decade of experience in laser cutting and sheet metal bending, Laserlam constantly looks to new solutions to increase its productivity, such as Prima Power’s new 2D Laser Genius+.

Prima Power EBe Express Bender Increases Productivity & Quality at Georgia Job Shop

When Randy Williams opened his job shop, he was already a seasoned fabricator. “I grew up with metal fabrication,” explains Williams. “My dad was an aerospace engineer who built trampolines part-time when I was 10 years old, and I helped build parts in the basement. His business evolved into making ferris wheels and other portable amusement rides, but eventually the liability insurance became too challenging for the small company.”