Prima Power in the HVAC sector

Find out what we do in the HVAC sector

Rapid industrialization, urbanization and improved living standards have favored the development of modern infrastructure, leading to an increase in demand for air conditioning, ventilation and heating systems. The trend is set to continue in the future, increasing the sales of HVAC systems worldwide.

The HVAC industry is characterized by high-volume production, even with low-volume batches or single parts. Combining productivity and flexibility is the main challenge in this industry.

Demand is increasing due to energy saving programs in the construction sector and the diversification of the product range.

The variety of materials used (e.g. galvanised steel, aluminium, stainless steel) requires very flexible systems to carry out the processing.

In this sector, quality is also a fundamental requirement. Products need to be tested and certified, so all systems involved in the manufacturing process need to be accurate and repeatable. Furthermore, subsequent machining must be avoided to increase productivity.

Most projects are cost-sensitive and therefore low operating, maintenance and labour costs, as well as reducing material waste, play a key role in the choice of systems to use.

DILIGENCE

We know that all systems involved in the manufacturing process need to be accurate and repeatable.

LISTENING

We customize our machines to your actual needs.

FLEXIBILITY

We are by your side through the design of your production, whatever it is.

Solutions

Find your ideal solution

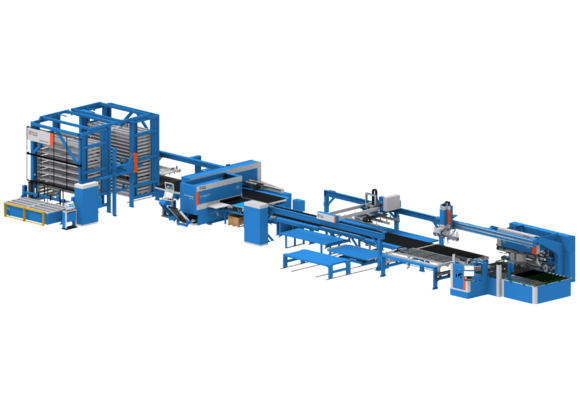

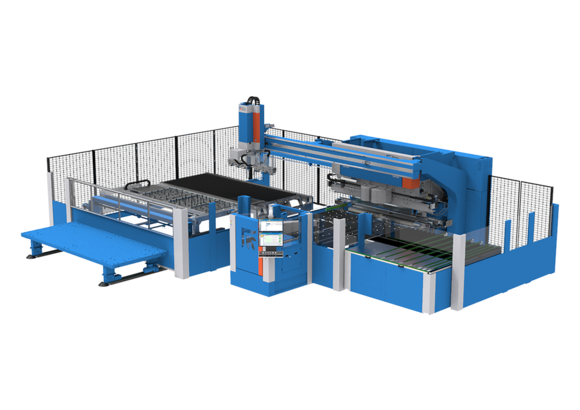

Our family of systems covers the main processes involved in the production of HVAC systems: cutting, punching, forming, drilling, shearing, bending, and welding. One single supplier means better process integration, more efficient material flow, greater ease of use of systems and better investments.

Our systems have been designed for flexibility: our punching machines can use a large number of different tools, integrated punch-shear systems allow you to process even diversified parts with a single machine, fibre laser cutting systems (alone or combined with punching systems) are ideal for thin gauges and highly reflective materials typical of this sector.

Our systems are suitable for both high volumes and small batch productions, depending on your needs: avoid overproduction, reduce finished parts stock and obtain "just in time" production.

Our efficient and versatile nesting programs allow you to make the most of the sheet metal, separate components quickly, and reduce cycle times.

Our panel benders are an excellent solution for processing components in HVAC products because they meet demands in terms of piece size, thickness, volume and batches.

The high quality of components (such as brushed stainless steel or pre-painted metal sheets) made with our machines eliminates the need for subsequent machining, such as deburring or painting, and also reduces assembly time.

Practically, there is virtually no limit to the complexity of components that can be made with our machines.

Our 2D laser products can be used not only for cutting profiles, but also for making tightly woven grids, which are common in this sector.

Our 3D laser machines can make tubes and profiles using a rotating axis. The weld line obtained with our laser head is thin and precise while the penetration depth control is extremely accurate. This means that strong, watertight welds with uniform characteristics can be achieved, allowing hydroforming with pressurized oil and the creation of channels for water circulation in a heat exchanger.

All of our systems feature minimal setup times and allow unmanned production.

Our wide range of automation modules enable highly efficient and flexible material flow and production without the need for supervision. These modules can also be added later, as budgets and production needs increase.

Our systems allow you to produce responsibly: more components at a lower cost, whilst respecting the environment with the "Green Means" approach.

Our services are an integral part of the product offering because they guarantee maximum availability and exploitation of your production capacity, as well as allowing future development.

Application examples

Behind each component there is a Prima Power machine

- sandwich panels

- covers

- grids

- ducts

- heat exchangers

Related technologies

Browse our technologies to choose your machine

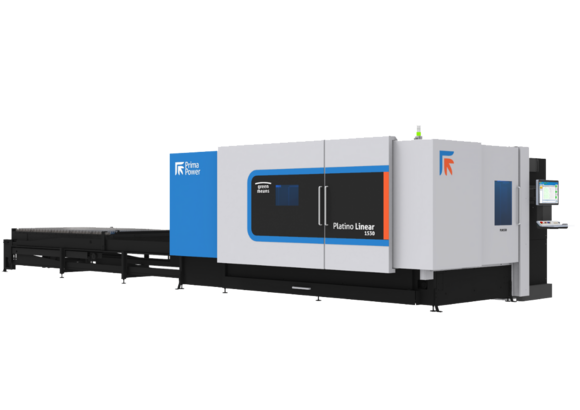

Platino Linear

2D LASER CUTTING MACHINE

The reliable and productive solution for cost-effective 2D laser processing

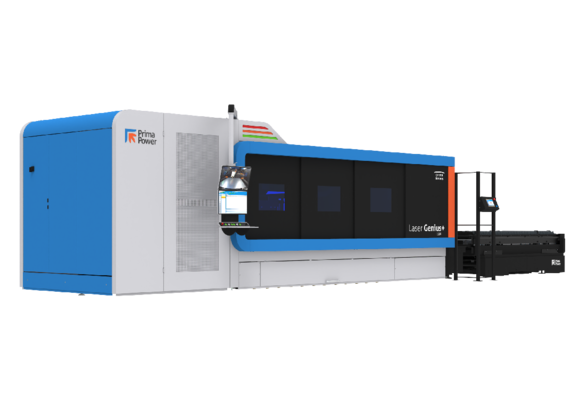

Laser Genius+

2D LASER CUTTING MACHINES

Prima Power laser machine faster, more precise, cheaper, for larger and heavier pieces.

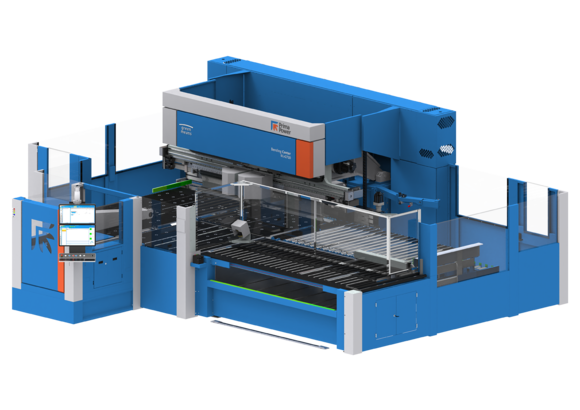

FBe Fast Bend

PANEL BENDERS

The answer to multiple applications. Semi-automatic bending solution for simple, flexible and accessible production

BCe Bending Centre

PANEL BENDERS

Flexibility at your service semi automatic panel bender combining flexibility and productivity

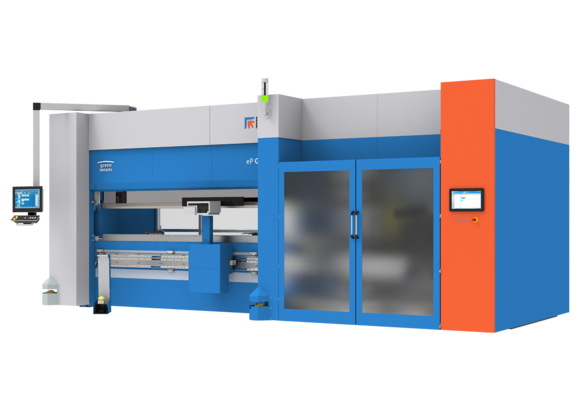

eP Genius

PRESS BRAKES

Efficient servo-electric bending solution with a fast and automatic tools change storage

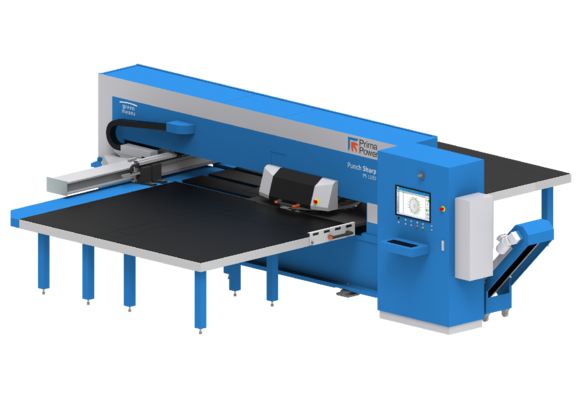

Punch Genius

PUNCHING MACHINES

Outstanding energy efficiency, low maintenance requirement and a high speed of operation.

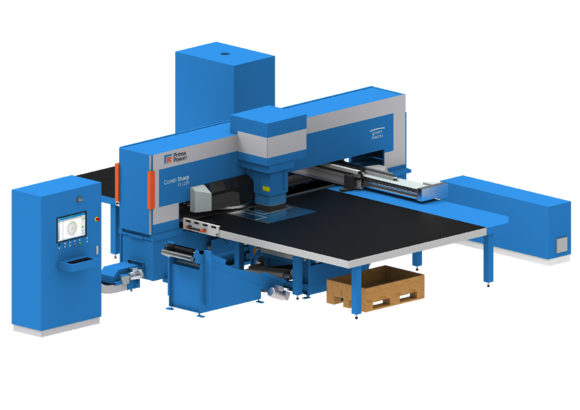

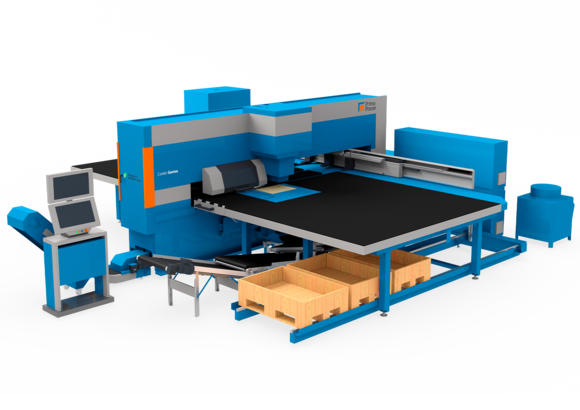

Combi Sharp

PUNCHING AND LASER CUTTING COMBINED MACHINES

Integrated punching and laser cutting at an affordable price

Combi Genius

PUNCHING AND LASER CUTTING COMBINED MACHINES

Punching + Laser cutting = Superior manufacturing economy

1+1>2

STORIES OF EVOLUTION

Find out how a Prima Power machine took part in an HVAC company's success

Brink Industrial | Vision: that all-human drive towards evolution

Discover Brink and Prima Power partnership, a success story made of human connections.

Facing Adversity and Winning with Prima Power Equipment

How many job shops could lose a customer that accounted for 98% of their business and recover in just a few years? Elm Machining was faced with that scenario several years ago.

New investments create productivity at Halton’s Kausala factory

Halton Group is the world's leading provider of indoor air solutions. Indoor air solutions are divided into four segments: Marine, Health, Foodservice, and Buildings

Laser Genius: a smart buy for Midwest Job Shop

For the past five years, R & M Manufacturing has faced an interesting challenge. The company has experienced a strong growth cycle, and projections are even stronger for the future with such customer industries as electrical, power generation, solar, air purification, HVAC, home & building, etc.

Platino Fiber Laser & Tower clear the air for higher productivity at ventilation manufacturer

Soler & Palau (S&P) Ventilation Group is the world’s leading fan manufacturer. The company offers a wide range of ventilation products benefiting from over 60 years of experience within the industry.