Brink Industrial | Vision: that all-human drive towards evolution

Discover Brink and Prima Power partnership, a success story made of human connections.

Wido and Andre smile from their PC screens. Like informal meetings they used to take interviews over a hot coffee in the break room, but since the beginning of the pandemic, each meeting opens with the same online ritual: “Do you hear me?", "Loud and clear, Wido!". Availability and kindness are always the same. Lieven is expected with the warmth of one of the family, they are happy to meet again and to talk about partnership that Brink and Prima Power have established years ago. Despite the extraordinary situation such as that of the pandemic that has imposed a massive use of technology and virtual connections, their relationship has become even closer.

How did you join the Brink group?

WvdB: Our company was established in 1903 and was specialized in deep drawing and metal spinning. Around 2000 it was acquired by the Brink Group as industrial supplier of ducts and pipes, which were the main activity of this factory in the past. I joined Brink in 2013, I bought almost half of the shares - the other half was owned by Mr Brink - and assumed the management of the company.

The two companies have always adopted an innovative approach to business and both for Brink and Prima Power, vision has always been clear: build a sustainable future through smart technologies and human connections.

How did the idea of focus the business on waste bins come about?

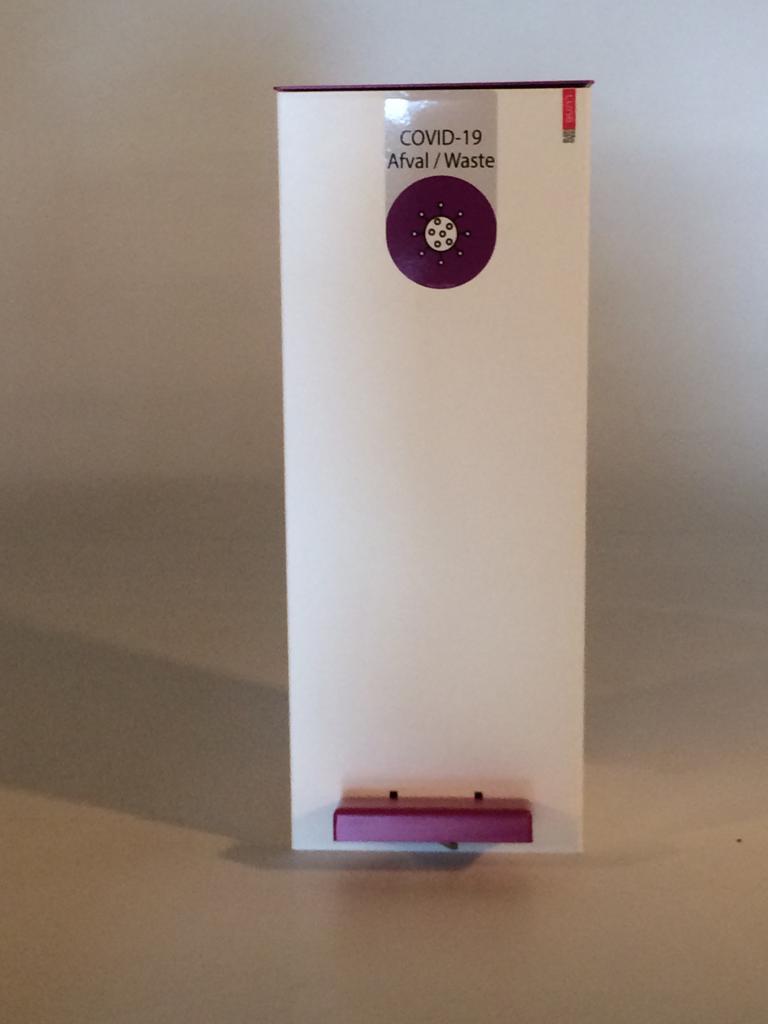

WvdB: We started to focus more and more on the waste bins because of the circularity aspect. I’m very much into sustainability and I saw huge market for separating wastes. We also manufacture litter bins with our own brand, Lune, and now we are market leader in that field of business in Holland and we are expanding in Europe. Some other projects are the server basis for Asperitas, a Dutch cleantech company leader in immersion cooling technology and the medical trays we supply to the company named Van Straaten Medical, a Dutch manufacturer of surgical instruments and disposables.

Distances imposed by the pandemic and the challenges due to Covid19 revealed the quality of human relationships and the importance of smart technologies.

What strengths convinced Brink to choose Prima Power as supplier?

AK: When I joined Brink 2 years ago, together with Wido we started to consider what we should do for the future and we understood that we needed to invest in new, smart machines that could allow us to increase productivity, smart industry is very important for us, together with sustainability. We looked around and investigated the possible options for the new machine and we understood that what we needed was a Prima Power line. In this machine we found something unique for the smart industry which allows us to enter new markets and gain new customers.

WvdB: In the choice of a supplier the technical and commercial side is very important, but we are a family old company and for us the relationship aspect is fundamental. This is also something we looked at during the purchasing process, the interaction between our points of contacts, and also compared with the competition, Prima was excellent. We had some challenges because of Covid19, since our machine was being delivered when the crisis started. The discussion with Prima on this aspect has been perfect. We were both realistic and we came to a deal very quickly and it is very good to see how things are excellently managed also during a crisis.

LL: It is a partnership. We had challenges due to the Covid-19. The Finnish team flew in to install the machine and few days later they had to fly back home because of the government request. They had to find solutions, on installation, on payment terms trying to do our best. Now the line is installed and operative.

What aspects guided you in choosing the LPBB new line?

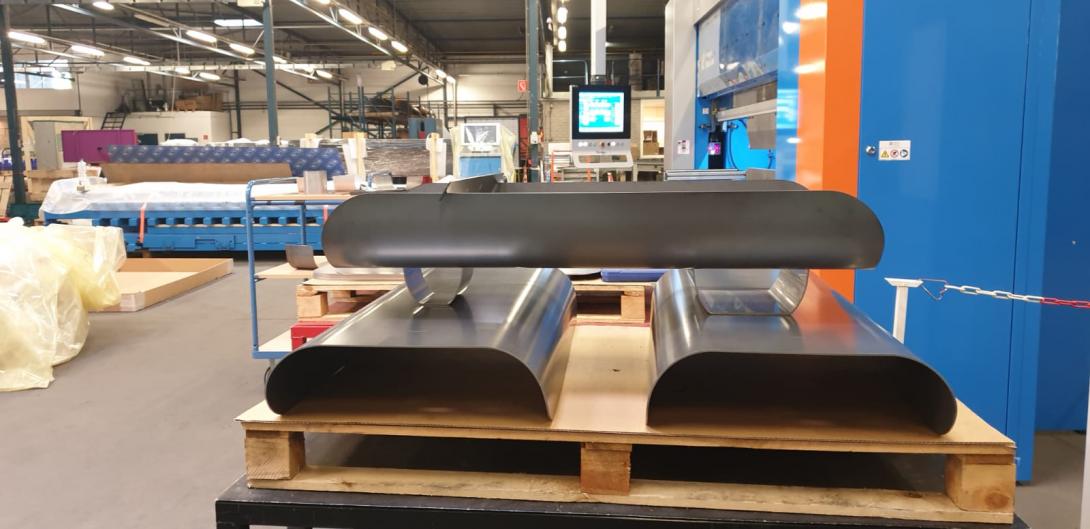

WvdB: There were several reasons why we decided to invest in new line by Prima Power: first, it’s an Industry 4.0 automated line that allows us to reach the quality and repeatability required by our customers. Secondly, the line is highly flexible so we can manufacture different parts on the same sheet and diverse products at the same time. Not least sustainability thanks to LPBB very little energy consumption that reduced CO2 footprint, also very efficient in the use of material and creates less scraps. This investment will help us manufacturing products following the concept of circularity and modularity is essential for circularity: we need to be able to separate the parts composing the product again and the line allows to create all types of connections between the parts.

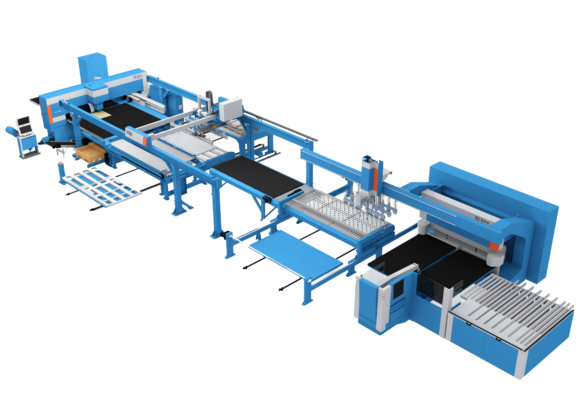

Connections, once again, was the added value that bring Prima Power on Brink's top of the list of suppliers with the LPBB new line. LPBB stands for “Laser cutting + Punching + Buffering + Bending” and integrates servo-electric punching plus fiber laser cutting (Combi Genius), servo-electric bending (EBe), automatic and versatile material flow and smart software. This combination allows for the very fast reaction times requested by modern production.

What is the aspect that you appreciated most of all?

WvdB: When we visited Prima in Finland we saw a truly integrated system. The competitors have the same elements, but they are not connected in the same way. With the LPBB we have all elements integrated in one line and they perfectly talk to each other. It is high-tech, but it’s not a close box, and if in the future we want to interchange one of the items within the line, for example a bigger laser, it will be possible. We cannot optimize the line only for one or two products, we need to be flexible and be capable of manufacturing different kinds of products for different kinds of sectors. Diversification is important, also in this crisis some sectors thrive and others are dead, so you need to be able to switch between those sectors. As all sheet metal companies we have seen a decline in the order intake due to the pandemic but with the new production line will bring us new opportunities. We are working with a new customer in Germany who came to us thank to the machine. We strongly believe that this system gives us an important competitive advantage, because it makes us super-flexible, super-fast and price-competitive. What we see now is that many companies which had offshored some productions are reshoring them because the Covid19 situation caused huge problems in their supply chain. With the new line we are ready to satisfy their needs.

The line is highly flexible so we can manufacture different parts on the same sheet and diverse products at the same time. Not least sustainability thanks to LPBB very little energy consumption that reduced CO2 footprint, also very efficient in the use of material and creates less scraps