Punching and Combined Technologies

Product families

Punching, Shearing & Combi: versatile solutions for your needs

Discover how Prima Power’s punching, shearing and laser cutting combined technology can optimize your production

Prima Power punching machines offer state-of-the art in servo-electric punching technology, but if you want to increase the versatility and productivity of your production, you can choose either a punch-shear or a punch-laser combination machine.

Choose the perfect Punching machine for you

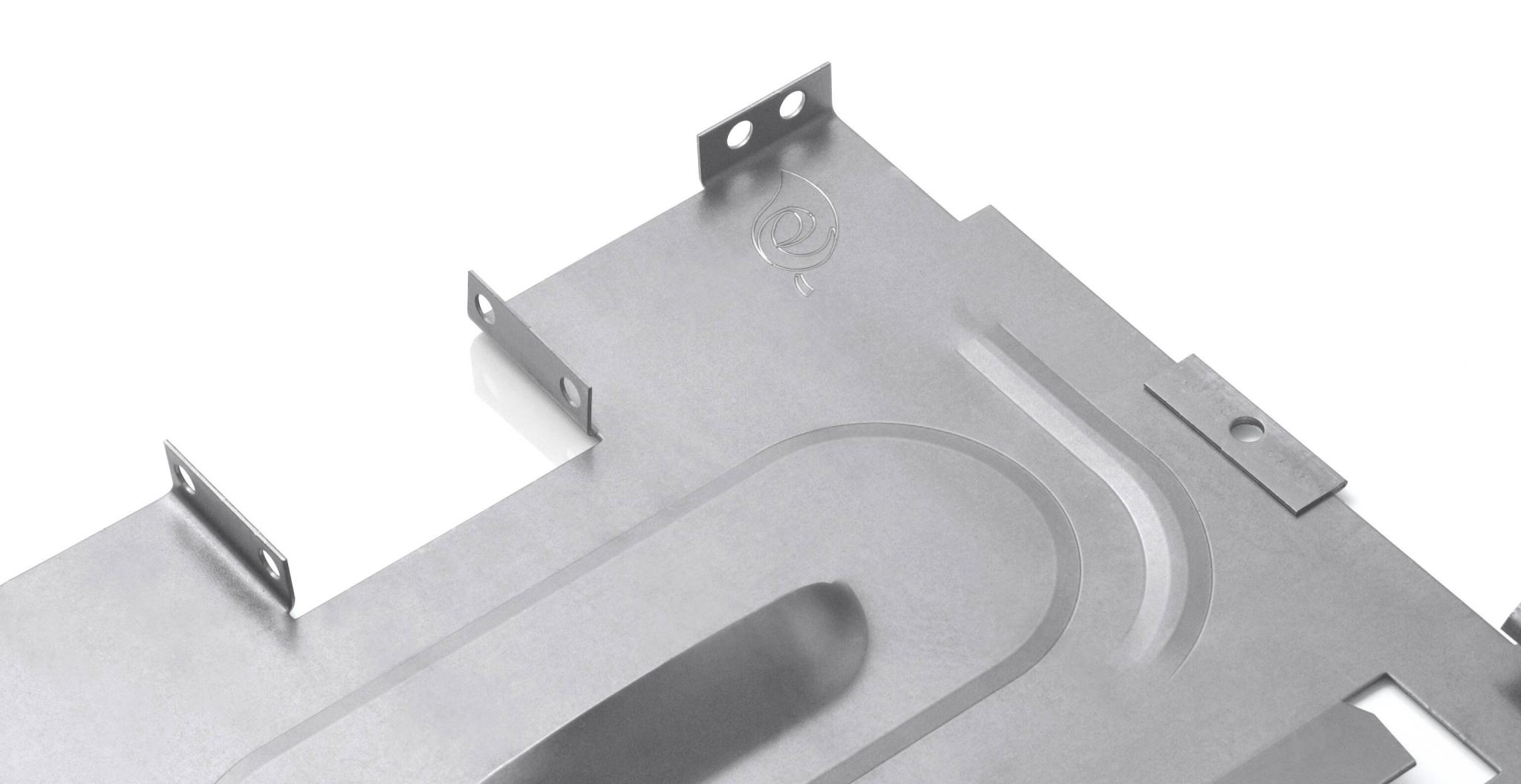

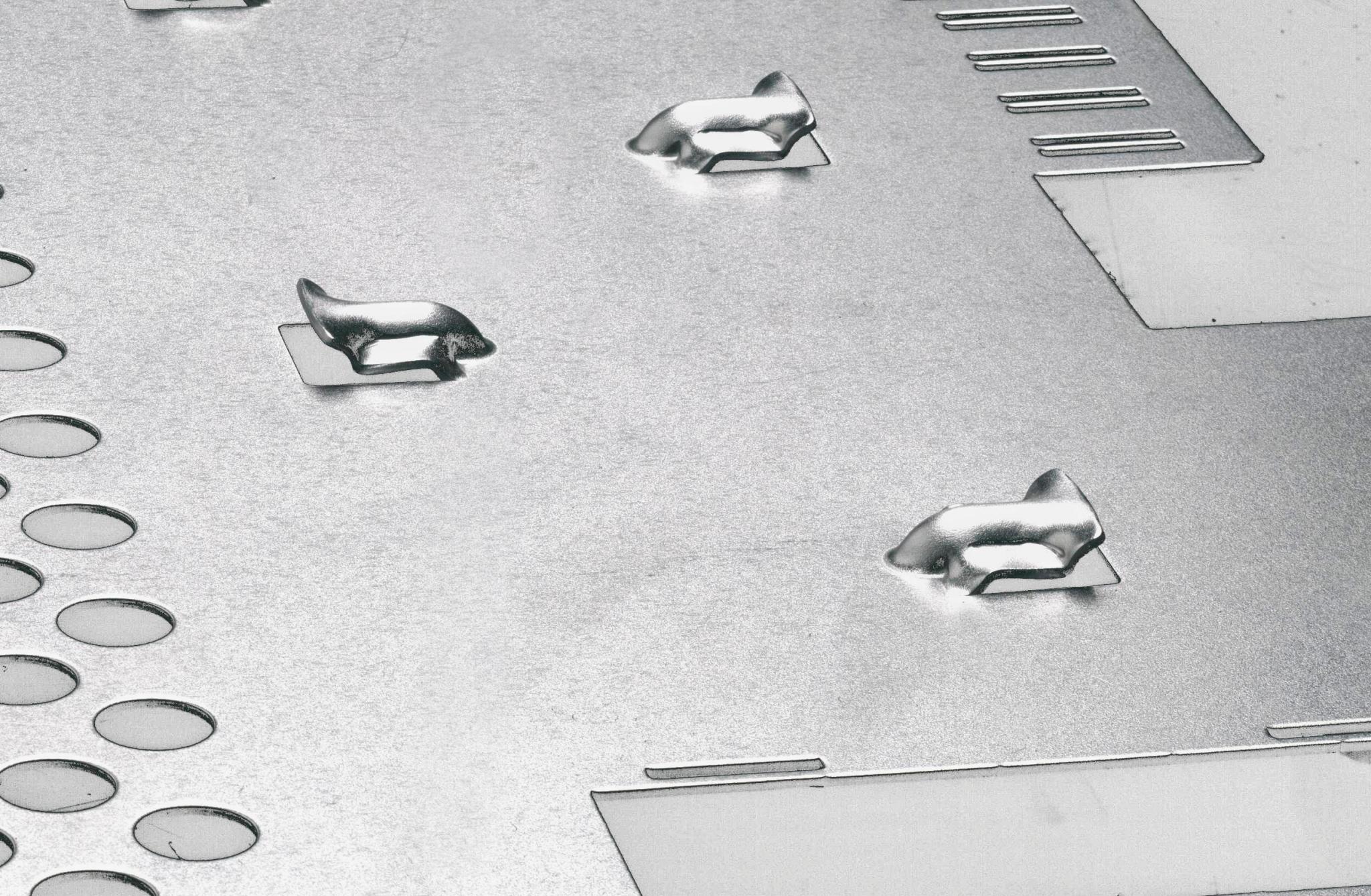

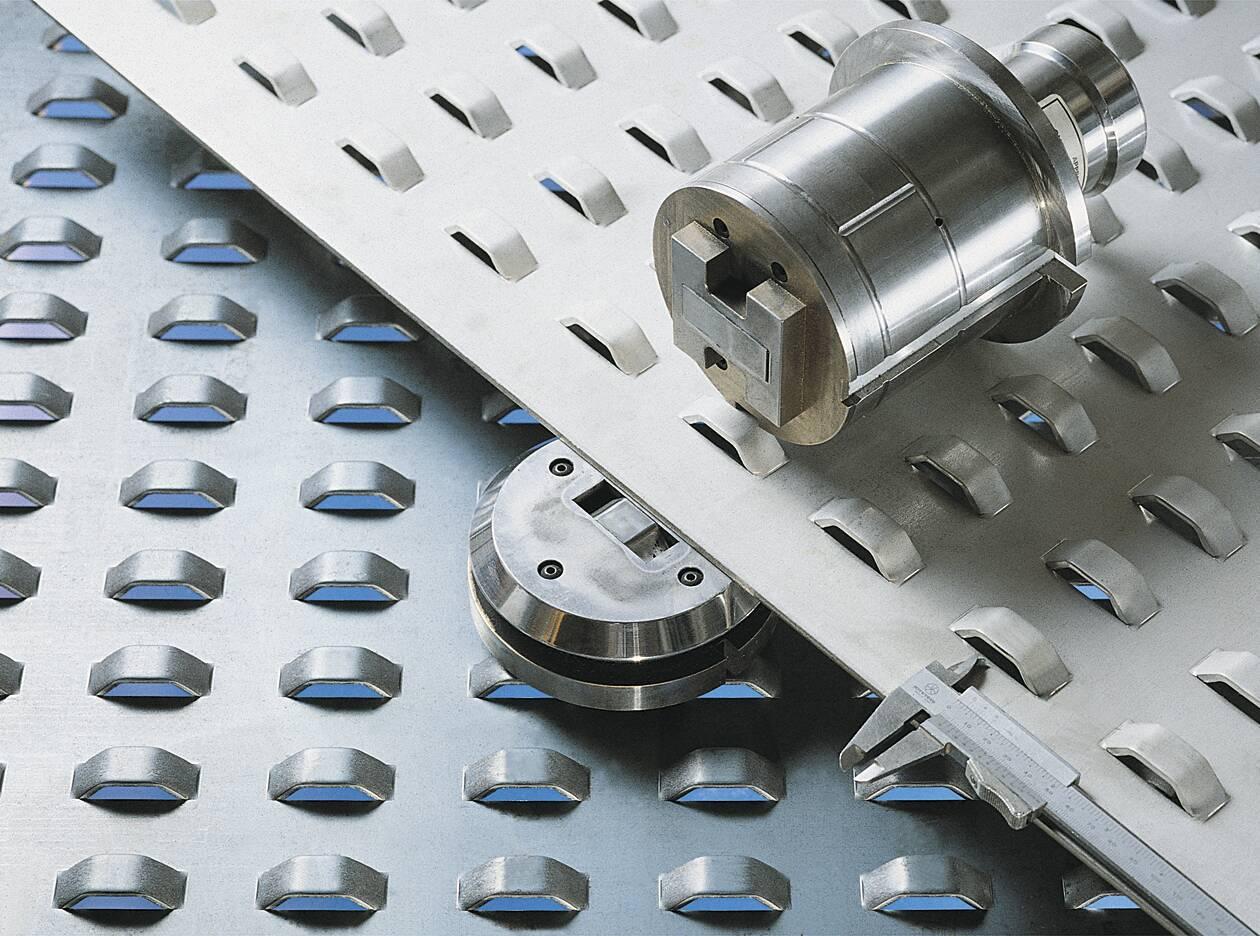

Prima Power Punching machines offer state-of-the-art servo-electric punching technology, based on pioneering experience, in an eminently flexible package. The genius of servo-electric punching is how it combines energy-saving and ergonomics with superb accuracy and productivity. And by using special tools, also forming, marking and tapping is possible.

Choose the perfect punching and shearing combined machine for your production

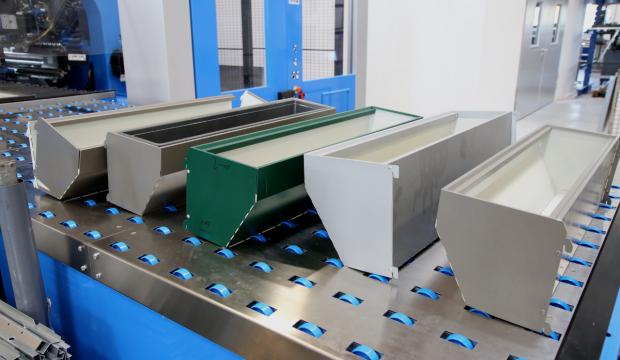

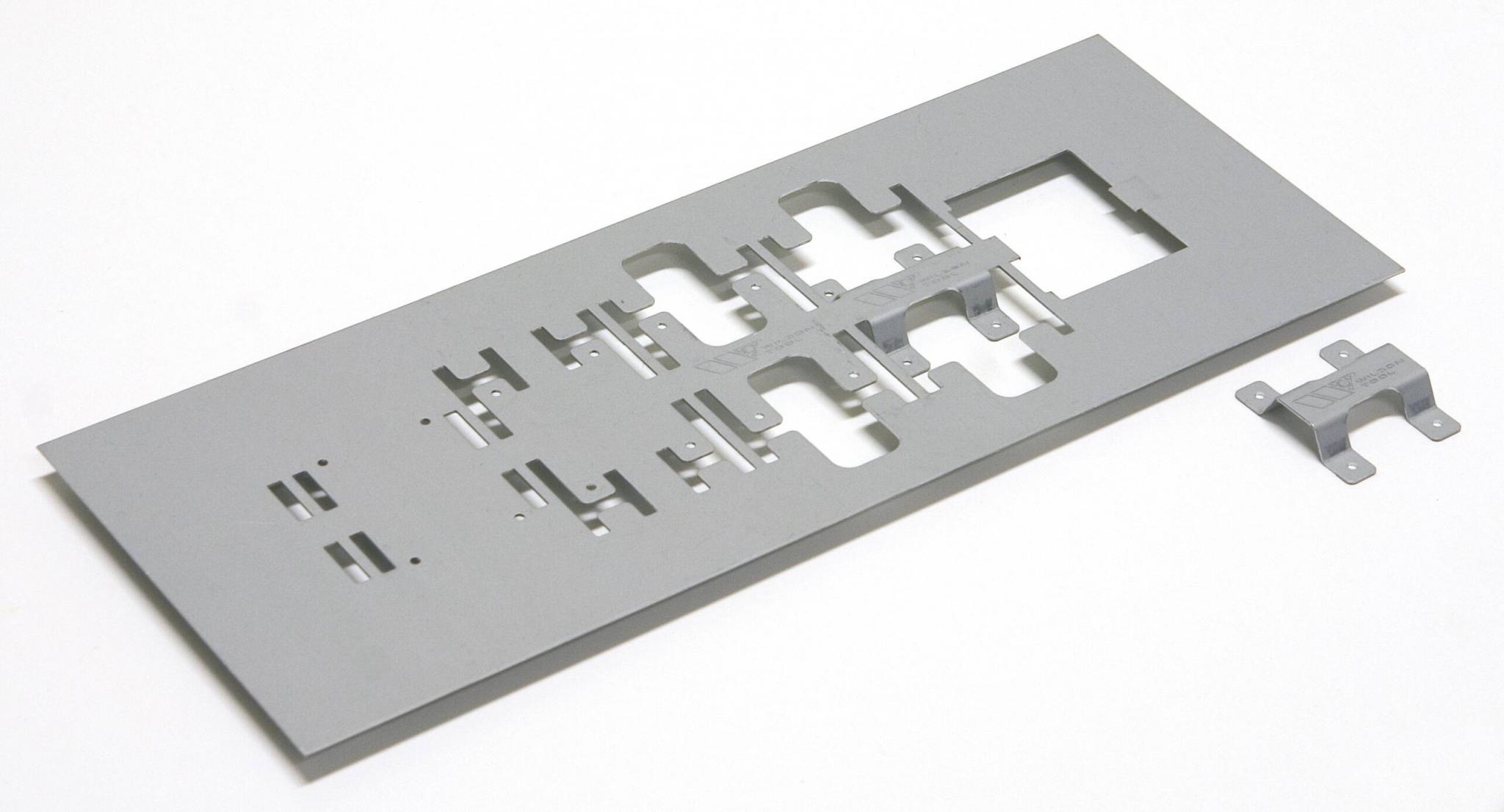

The vast majority of sheet metal components manufactured are rectangular, so a highly economical method of producing them is to first punch and then shear the components in the same automated process with an integrated right-angle shear. Furthermore, parts with two or three straight edges are perfect for fabrication with a right-angle shear. The punching and shearing concept saves material, decreases necessary floor space and investment in separate machine tools, tooling and energy.

Choose the perfect punching and laser cutting combined machine for your production

Punching + Laser cutting = Superior manufacturing economy

Prima Power Combi machines have a small footprint but offer productivity, convenient operation and compatibility with various automation solutions. With Prima Power combi-lasers, you can achieve high quality and produce even the most complex parts by utilizing both fibre laser cutting and punching technology where they suit the best.

Discover our Punching and Laser Cutting Combined product range

Choose the perfect Punching, Shearing & Combi machine for you

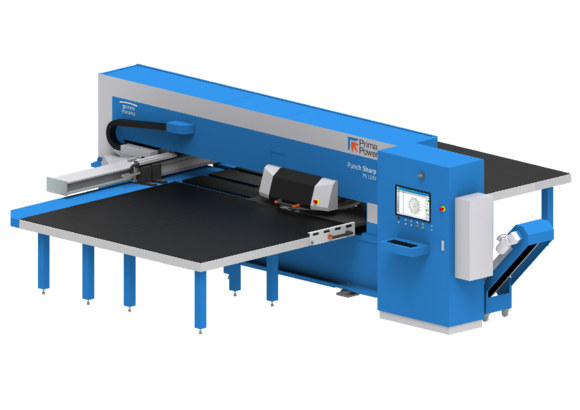

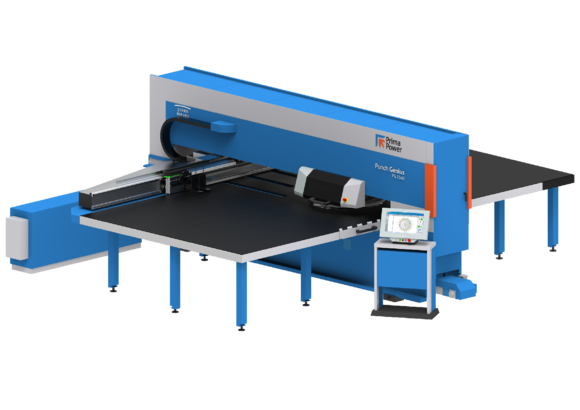

Punch Genius

PUNCHING MACHINES

Outstanding energy efficiency, low maintenance requirement and a high speed of operation.

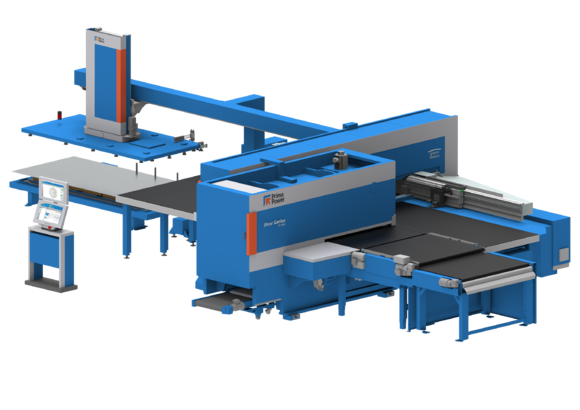

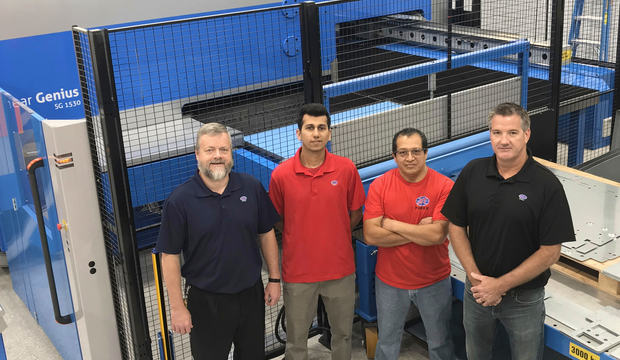

Shear Genius

PUNCHING AND SHEARING COMBINED MACHINES

Highest productivity with integrated punching and shearing

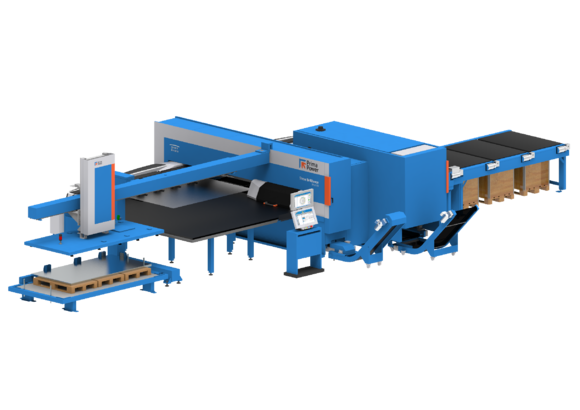

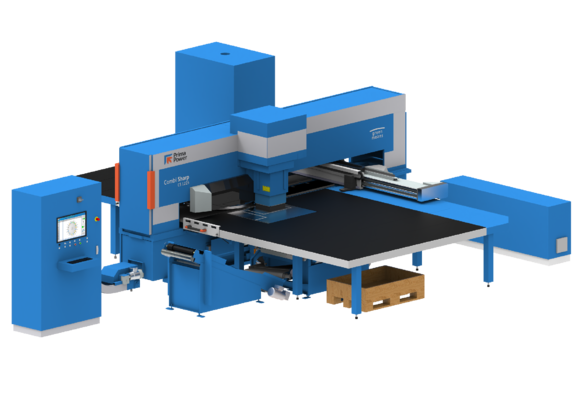

Combi Sharp

PUNCHING AND LASER CUTTING COMBINED MACHINES

Integrated punching and laser cutting at an affordable price

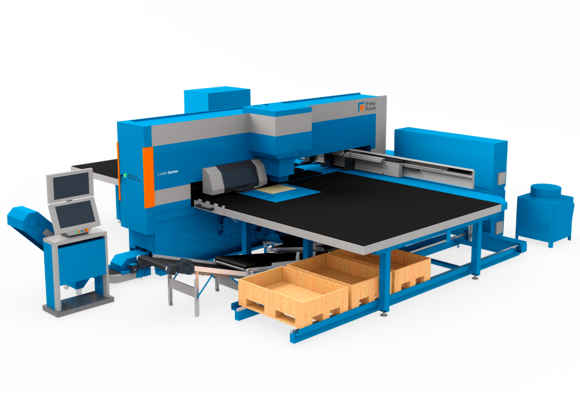

Combi Genius

PUNCHING AND LASER CUTTING COMBINED MACHINES

Punching + Laser cutting = Superior manufacturing economy

1+1>2

STORIES OF EVOLUTION

Find out how Prima Power punching, shearing and laser cutting combined technology took part in a company’s success

JST Power Equipment, having the right facilities to say ‘yes’ to clients is priceless.

Switchgear lineups are engineered-to-order products with a lot of variation among jobs, including fabricated sheet metal parts. Enabling the new JST Power Equipment switchgear-manufacturing plant to excel at taking on low-volume production: an automated punch-shear combination machine.

Alvi | A perfect combination for the medical sector

Aluminum and stainless steel are the materials used by Alvi to produce trolleys for the hospital, laundry, retirement home, hotel, industrial and textile sectors.

Biohort | Deluxe sheet metal processing

The construction phase of the new Biohort manufacturing site in Herzogsdorf (Upper Austria) lasted just over a year. With cutting-edge industry standards and optimised process cycles, the specialist for storage space solutions created new resources for further growth with new Plant 2, an addition to its Neufelden headquarters.

New investments create productivity at Halton’s Kausala factory

Halton Group is the world's leading provider of indoor air solutions. Indoor air solutions are divided into four segments: Marine, Health, Foodservice, and Buildings

Punch-Shear Combo – A Labor Saver

Shear and punch fabrication of sheetmetal parts at custom door manufacturer LaForce, Inc. more than triples thanks to implementation of a new servo-electric punch-shear combination machine.

A look at the technology behind turnkey organic poultry plants

SKA srl manufactures poultry systems for organic free-range farming with high levels of product customisation by taking advantage of innovative Prima Power technology.

A&J precision sheetmetal | Silicon Valley Job Shop Achieves Success with Prima Power Machines

Since A & J Precision Sheetmetal Inc., San Jose, CA, first opened its doors in 1995, the company has earned a stellar reputation as a leading job shop producing high-quality precision parts in the demanding Silicon Valley.

Future fit with the punch laser machine

Eisenwerk Wittigsthal GmbH invests in a punch-laser system so as to be ready for the digital future.

Riding the Night Train to Higher Productivity

The Minerva Group in Bologna, Italy is a company that truly embodies skills, technology, and entrepreneurial spirit.