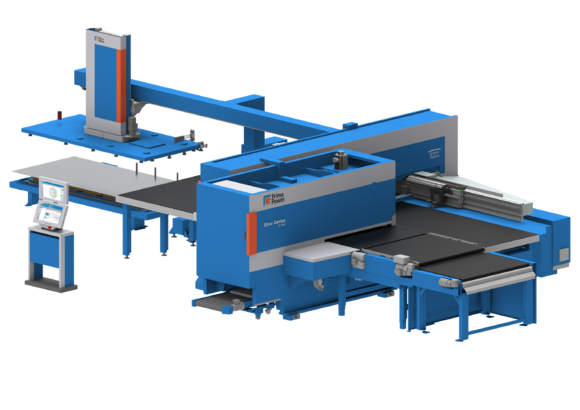

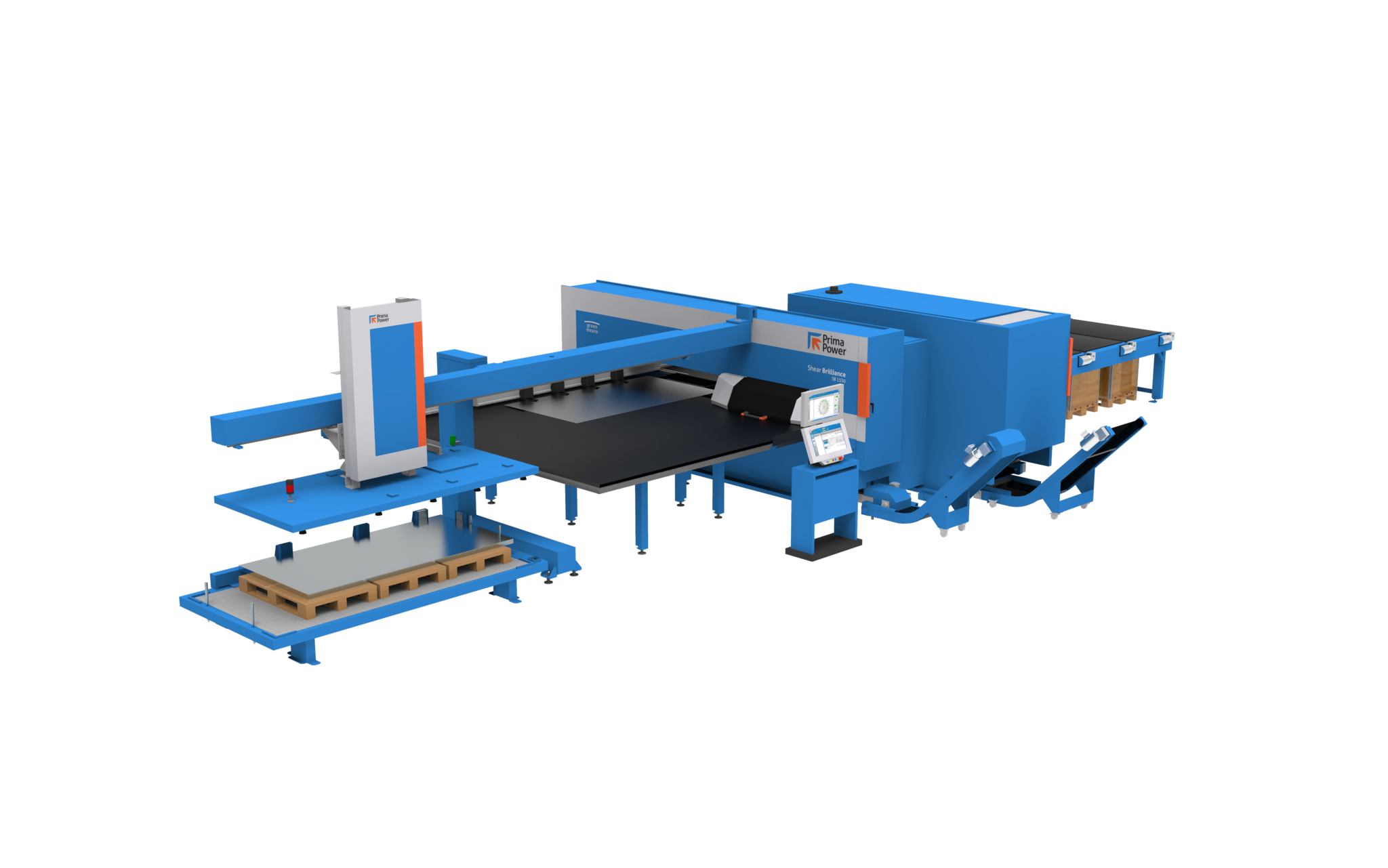

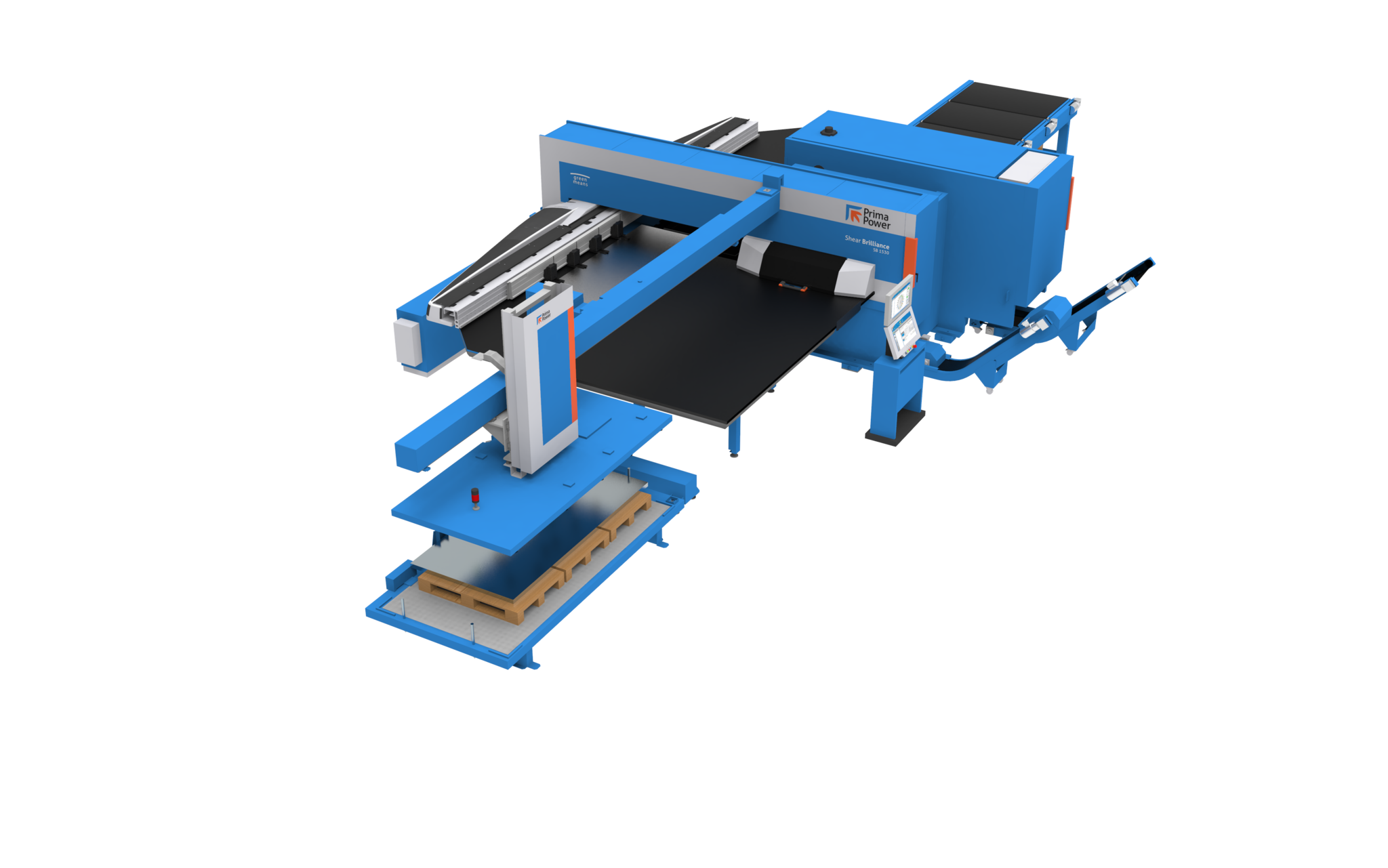

Shear Brilliance

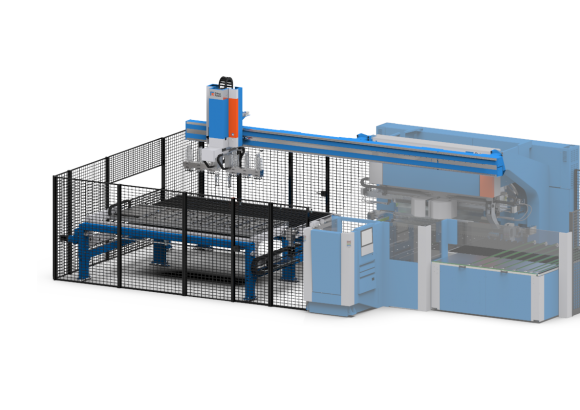

PUNCHING AND SHEARING COMBINED MACHINES

Outstanding productivity

FAST

Hit speeds up to 1,300 hpm. Fastest hit rate available for fabricating full format sheets.

ACCURATE

Supreme positioning speed, accuracy and precision. Time savings and improved quality during processing.

EASY

Automated flexible fabrication. Less manual labour, higher throughput.

SMART

Savings in raw material: no skeletons, less punching scrap.

Prima Power Shear Brilliance is ideal solution for manufacturing big square parts and panels. It is based on the very latest in composite materials, servo-electric technology, and linear drives to achieve truly impressive performance values which translate into a new level of productivity in versatile, flexible fabrication.

The vast majority of all sheet metal components fabricated are rectangular, so a highly economical method to produce them is to perform first punching and then shear the components loose in the same automatic process with an integrated right angle shear. Also, parts with three or two straight edges are perfect for fabrication with a right angle shear.

The Prima Power right angle shear is extremely fast in operation. Programmable blade height and automatic stroke depth adjustment optimize shearing. The blade speed is automatically selected for the maximum speed. Together with automatic shearing modes, this optimizes operation speed.

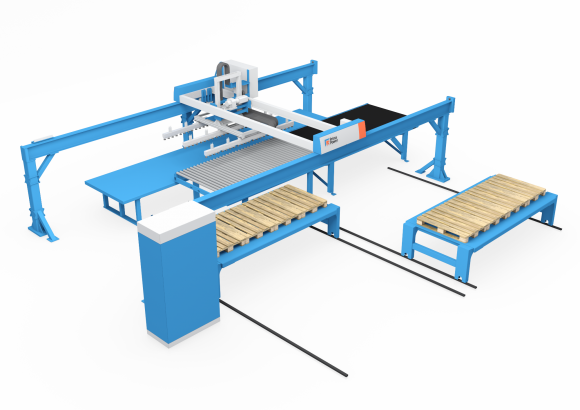

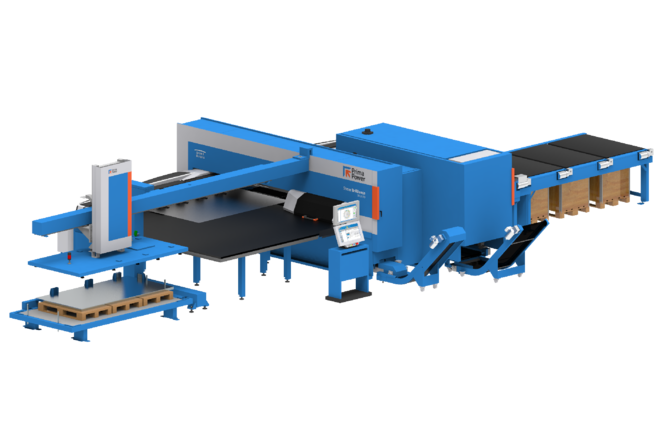

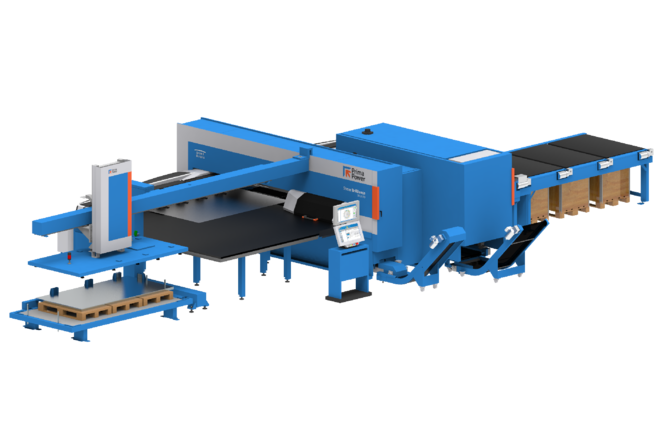

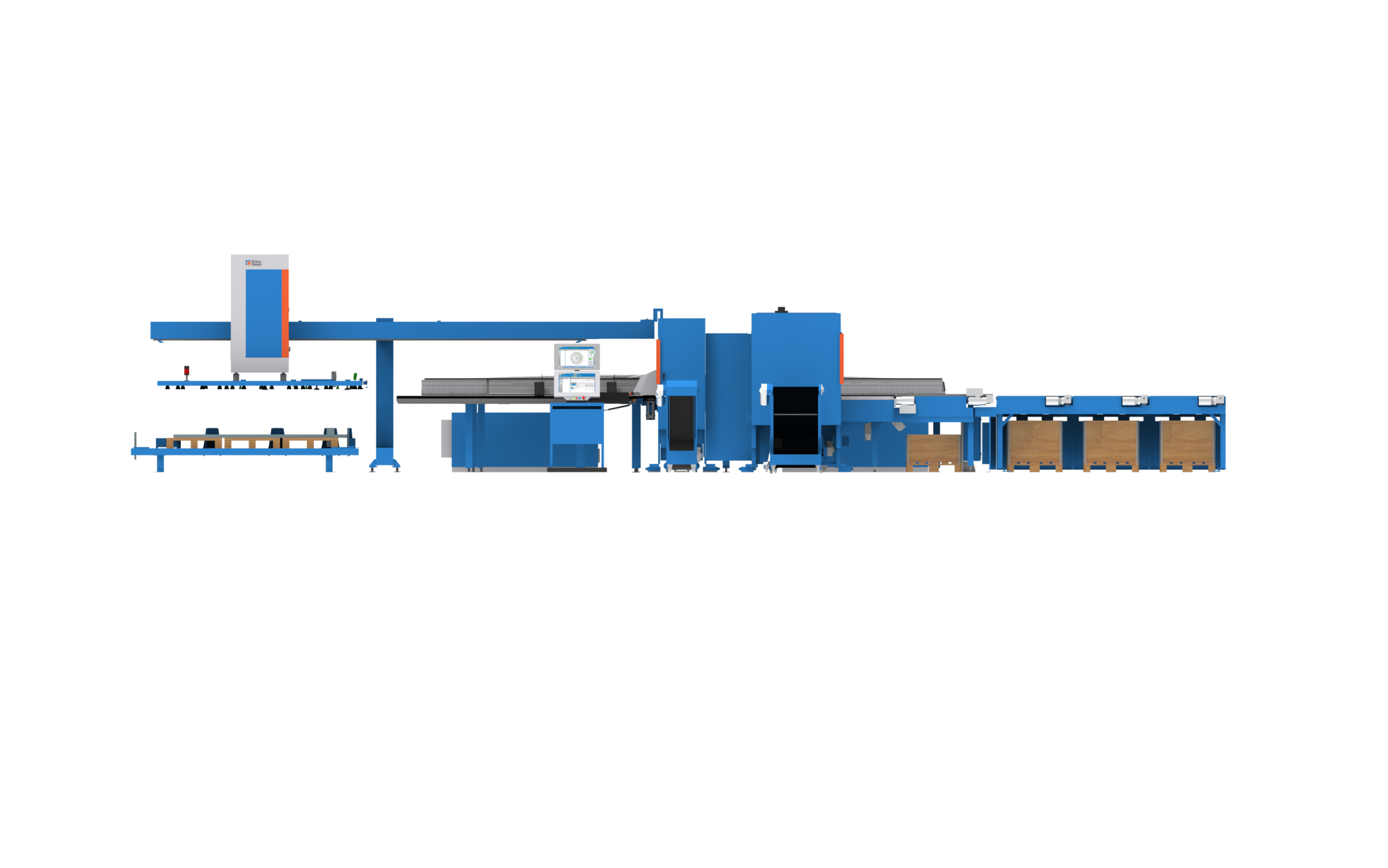

Shear Brilliance can be easily connected to automation systems in order to automatize the material and part flow and further increase the output.

Prima Power's ECOPUNCH® concept is an astonishing money saver in terms of energy consumption. Compared to the traditional method Prima Power can produce more parts at the same energy.

HIGHLIGHTS

Loading in hidden time

more production time available

Hit speeds up to 1,300 hpm

fastest hit rate available for fabricating full format sheets

3,100 mm common working area

punching and shearing without repositioning

More force (300kN / 33 US tons)

Complicated contours with one hit

High tooling capacity

huge savings in set-up times, flexibility in production

Supreme positioning speed, accuracy, and precision

Time savings and improved quality during processing

Prima Power Shear Brilliance is an ideal solution for manufacturing big square parts and panels.

AUTOMATED FLEXIBLE FABRICATION

Less manual labour, higher throughput

SAVINGS IN RAW MATERIAL

No skeletons, less punching scrap

HIGHER NESTING UTILIZATION

More parts in one sheet

HIGH QUALITY

No nibble marks in part edges

FAST, ACCURATE AND RELIABLE SHEARING AND PART EXIT

Less labour, better part quality

LARGE TOOLING CAPACITY

The large number of tools with Prima Power punching machines results from a set of technical features which is not available from any other manufacturer:

- Two turret construction alternatives: 24 and 30 stations

- Multi-Tools®

- A vast variety of special tools

- Rotating Auto-Index system

- Intelligent ram

Max sheet size

SB1530 3,100 mm x 1,565 mm

SB1540 4,300 mm x 1,565 mm

Total work area X x Y without repositioning (loading-punching-shearing) (SB1540)

X movement 5040 mm

Positioning speed up to 210 m/min

Ram force 300kN (33 US tons)

Max. tools in turret / Max. index tools 600 / 576

Hit speeds

1 mm 1,300 hpm

25 mm 580 hpm

250 mm 235 hpm

marking 3,000 hpm

Optimize your Prima Power machine

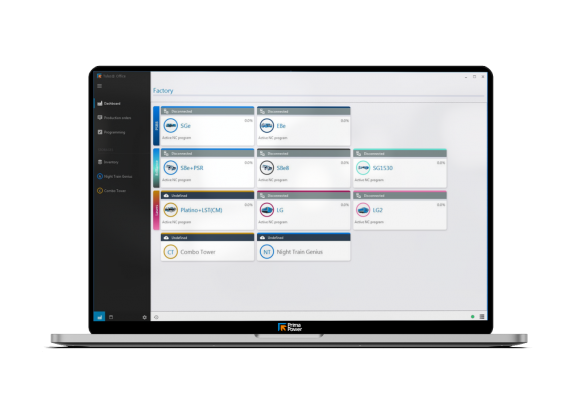

Tulus Cell

H.M.I.

Integrated and scalable software family for centralized management of fabrication.

Tulus Office

PRODUCTION PLANNING

Work planning and controlling all machines in the factory.

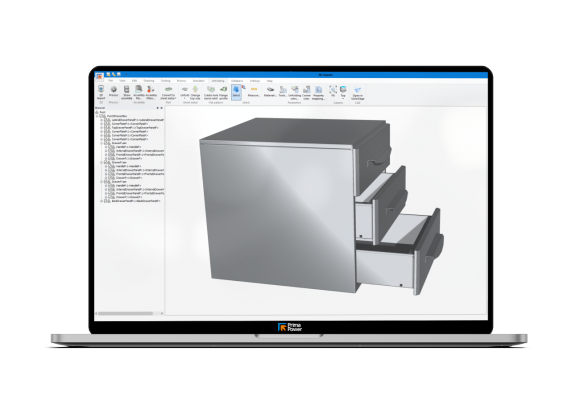

NC Express

MACHINE PROGRAMMING

Scalable CAD/CAM application that can be used for single part processing or as fully automatic batch processing software.

Tulus Analytics

PRODUCTION REPORTING AND MONITORING

Parts production and machine performance reporting

Related technologies

RELATED AUTOMATIONS

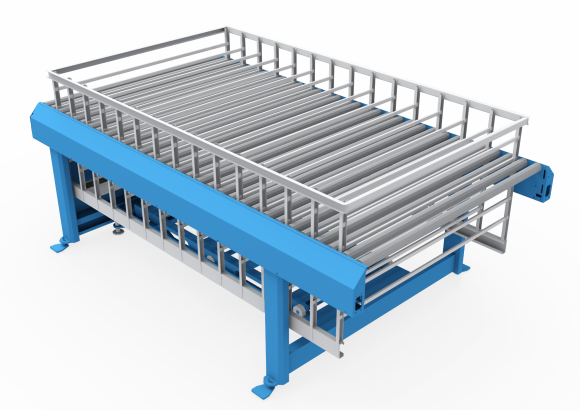

Sheared part sorting conveyor (C1500)

MATERIAL HANDLING

Automatic sorting of small sheared parts

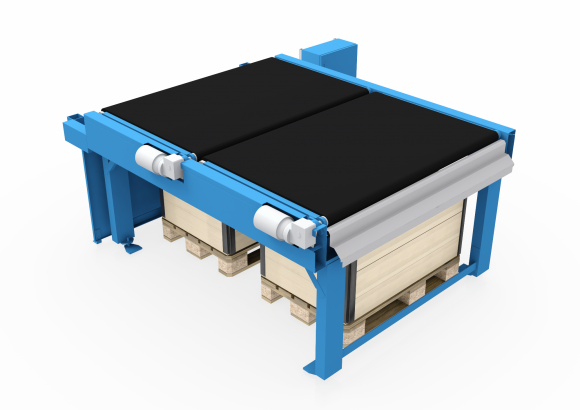

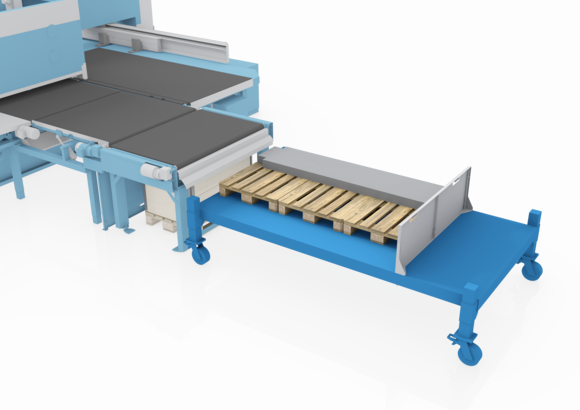

Sheared part buffering (SPB)

MATERIAL HANDLING

Sheared part buffering (SPB)

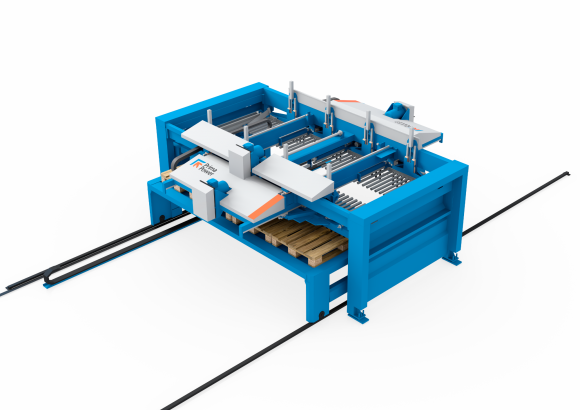

Picking and stacking robot (PSR)

MATERIAL HANDLING

The clever and flexible picking and stacking robot

Sheared part stacking system (STS)

MATERIAL HANDLING

A high capacity stacking solution for sheared parts

Easy sorting table

MATERIAL HANDLING

An entry-level sorting solution for punch-shear combined machines

Connection to automatic bending

MATERIAL HANDLING

Direct connection to Express Bender for part bending

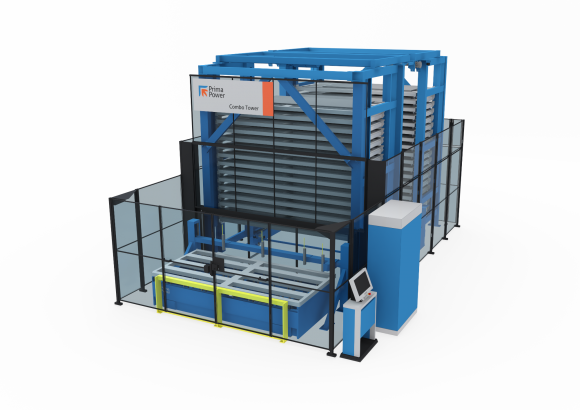

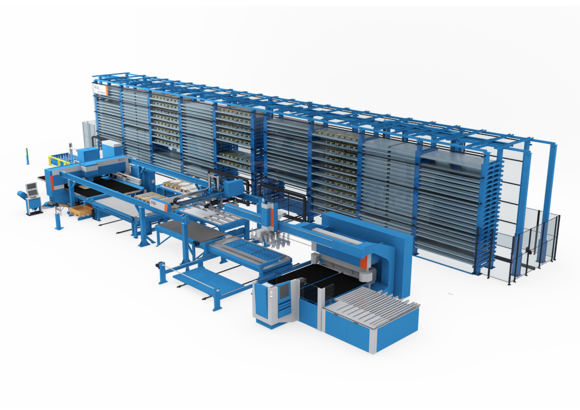

Night Train FMS®

FLEXIBLE MANUFACTURING SYSTEMS

Leading technology storage solution in automated flexible manufacturing systems

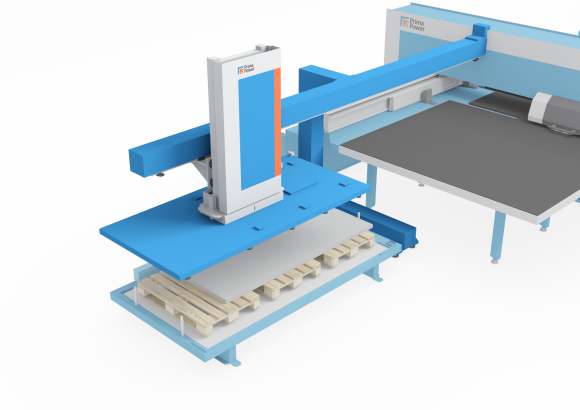

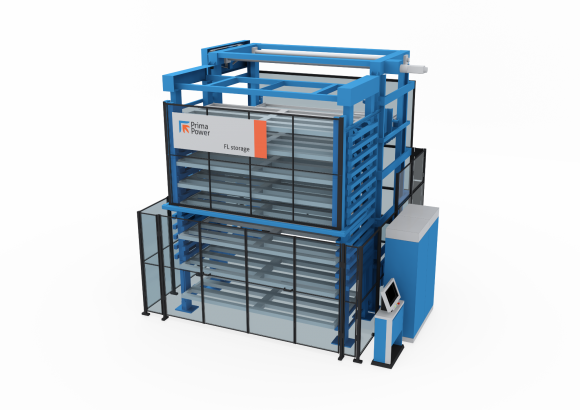

Fast Loading storage

STORAGE SOLUTIONS

A fast and economical solution for material flow

Take a look at the other products and choose the best solution

Shear Genius

PUNCHING AND SHEARING COMBINED MACHINES