NC Express

MACHINE PROGRAMMING

Scalable CAD/CAM application that can be used for single part processing or as fully automatic batch processing software.

Reliability, efficiency and speed in production

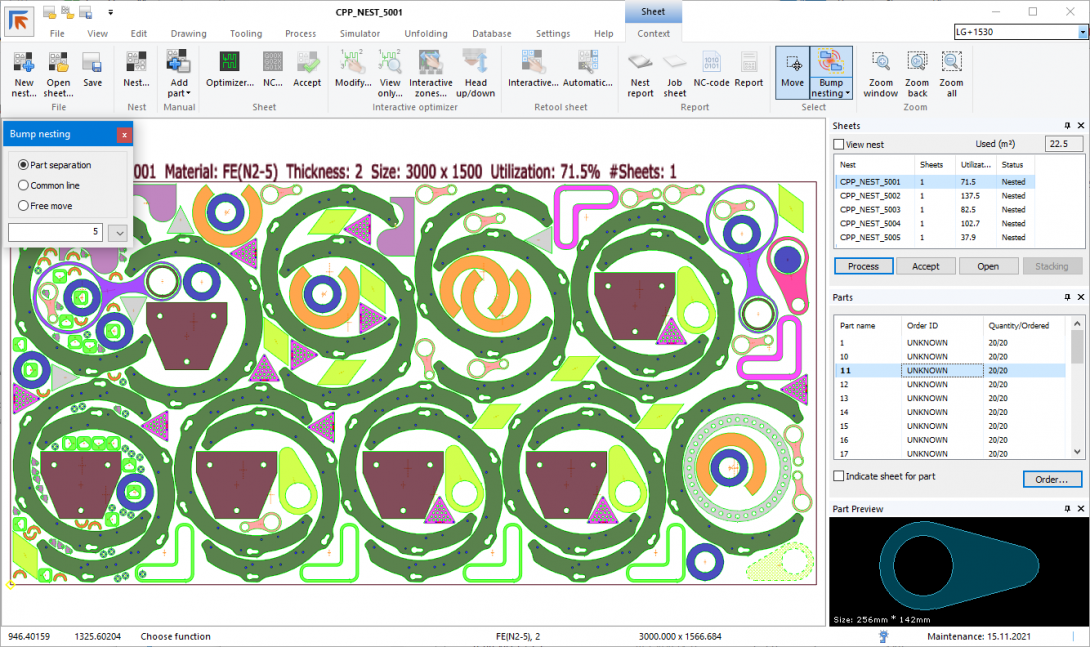

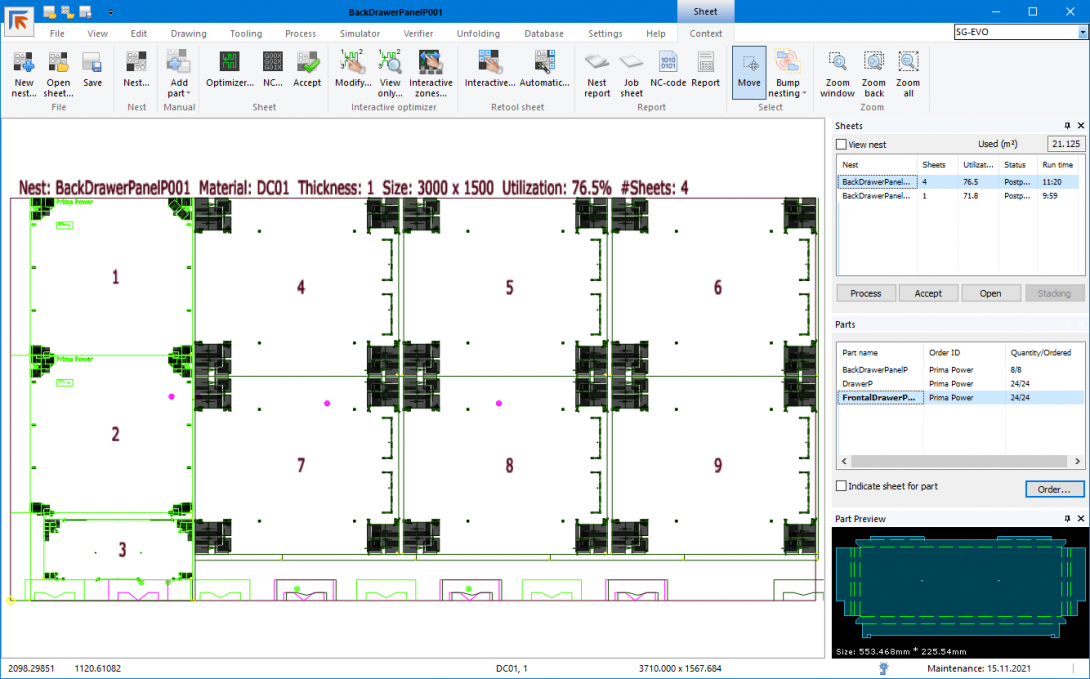

Automatic nesting for punching, shearing and laser cutting

Parametric Programming

Support for standalone machines and big automated systems

Flexibility - from manual part preparation and manual nesting to fully

Automatic processing

Erp Connection

NC Express is Prima Power's CAD/CAM programming ecosystem for programming 2D Laser, Combi, Shear, Punch, Panel Bender (BCe and EBe) machines, Systems and automation.

The programming system is a user friendly, integrated and automated tool for managing Prima Power equipment in the most efficient manner. It is a scalable application - the system may be used as a single part drafting and tooling program or as a fully automatic machine tool programming system. Either way the results are the same optimized automatic NC-code creation.

NC Express is part of Prima Power software family designed to work seamlessly together with Prima Power machines and Tulus® Office software.

- Full CAD package, 2D import, 3D import (option)

- Unfolding

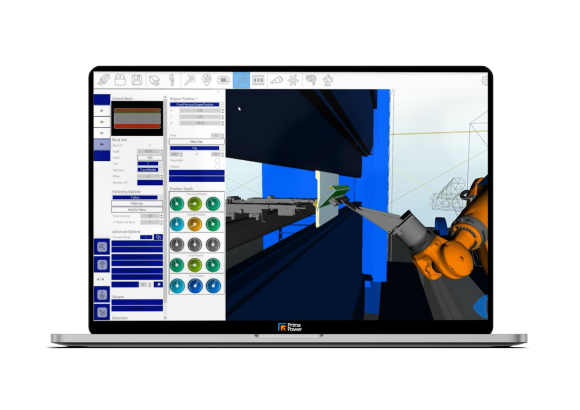

- BCe and EBe manual functions for manual programming

- Bending easy interactive and visual program editing

- Bending validation of the program with collision check

- Tree-view structure of the Bending Process

- BCe and EBe manual functions for manual programming

- Bending easy interactive and visual program editing

- Bending validation of the program with collision check

- Tree-view structure of the Bending Process

- Parametric programming

- Orders Management System (MRP/ERP connectivity)

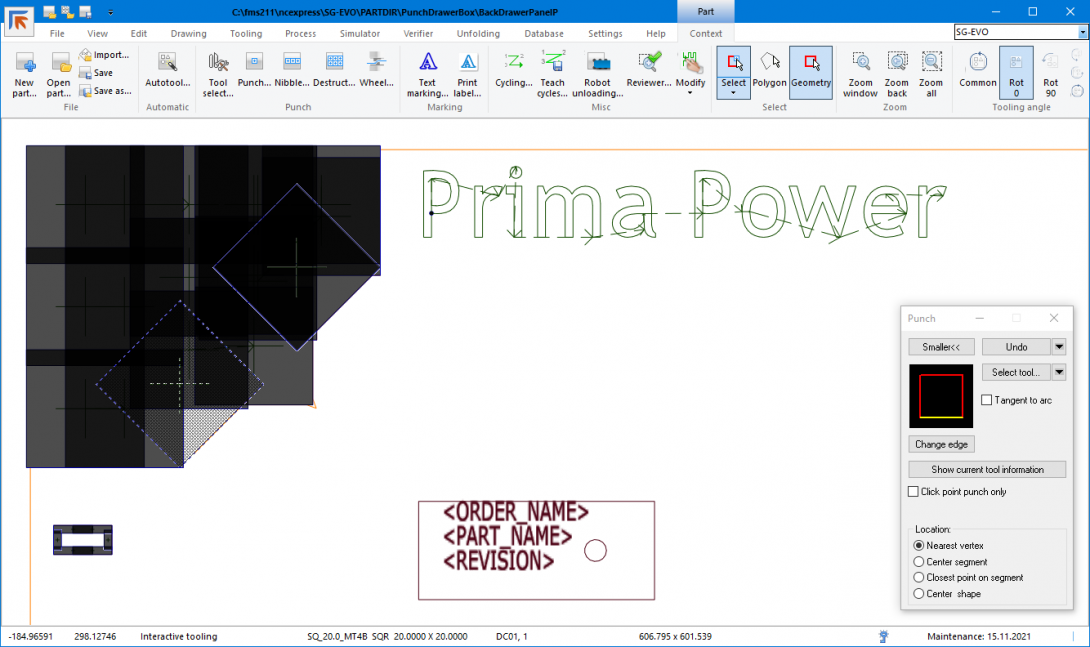

- Ability to teach tooling to geometric entity (e.g. Knockout, punch & form, etc.)

- Automated programming

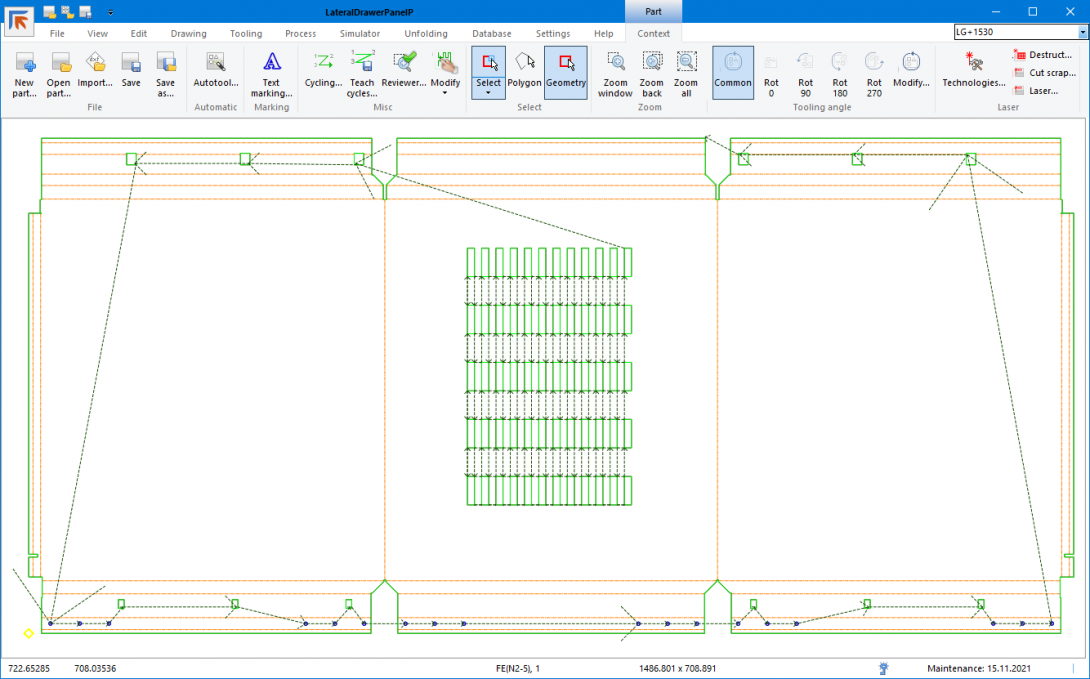

- Automatic tooling for punch, shear & laser

- Automatic nesting for punch, shear & laser

- Automatic true shape random part nester

- Common line cutting

- Fully automatic machine optimization

- Automatic clamp setting to minimize “dead zones”

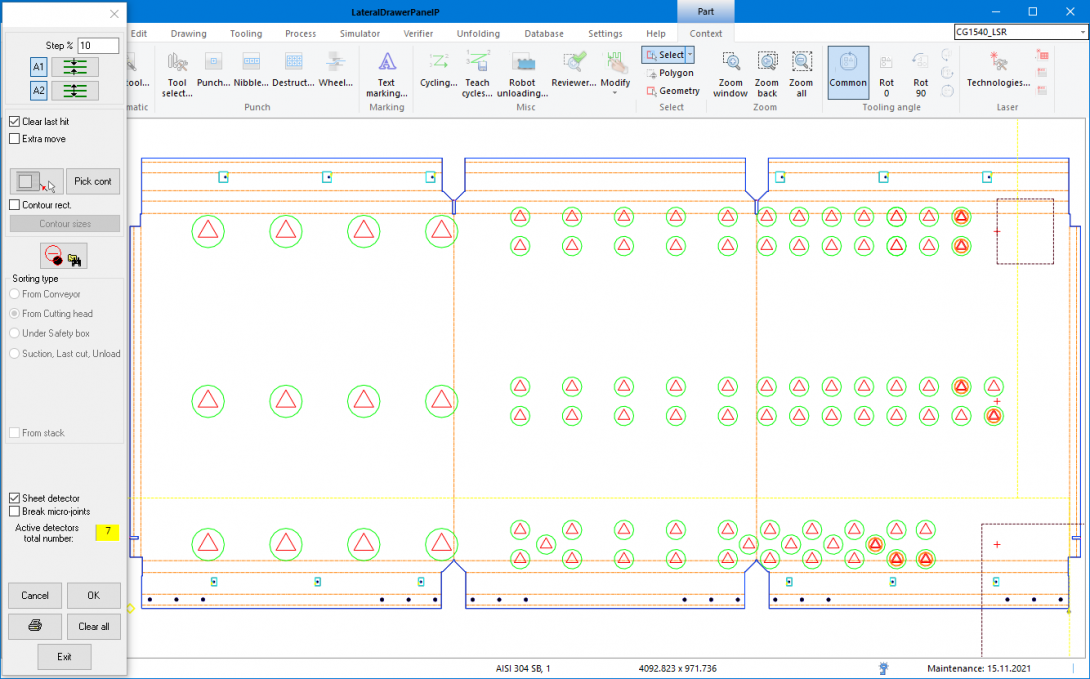

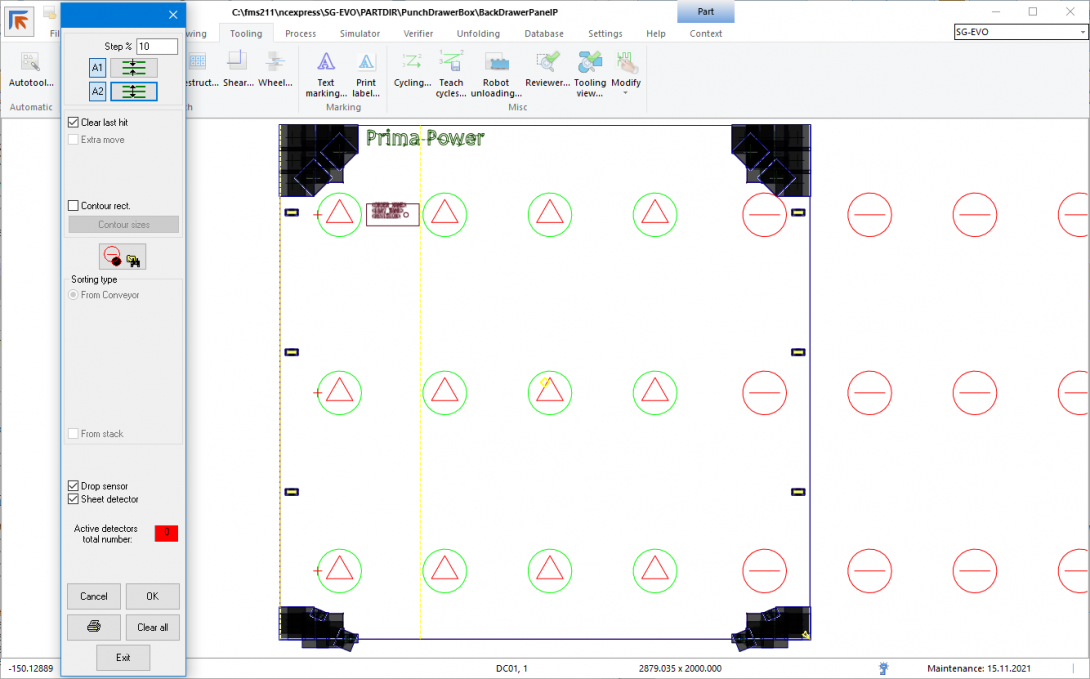

- Automatic part sorting and stacking for automated systems

- Index & Multi-tool optimizations

- Laser high speed grid cutting (DPM+)

- Full setup and production reporting for operators and management

- Cost reporting

- Time estimations

- Bevel cutting

- PDM Integration

- Edit model in 3D-CAD

- Import extensive range of 3D- and 2D-drawing files: DXF, DWG, STEP, IGES, ACIS, Parasolid, Catia V4/V5/V6, Creo, NX, Inventor, Solid Edge, SolidWorks and proprietary formats

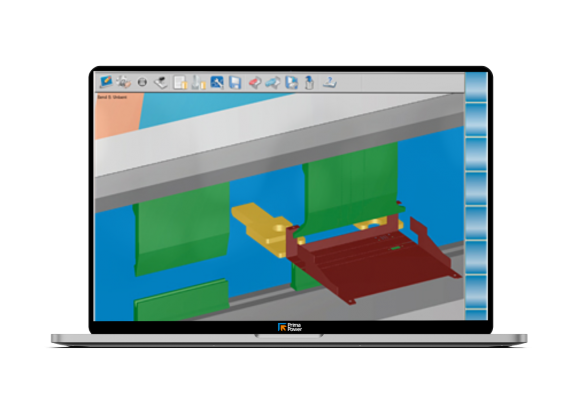

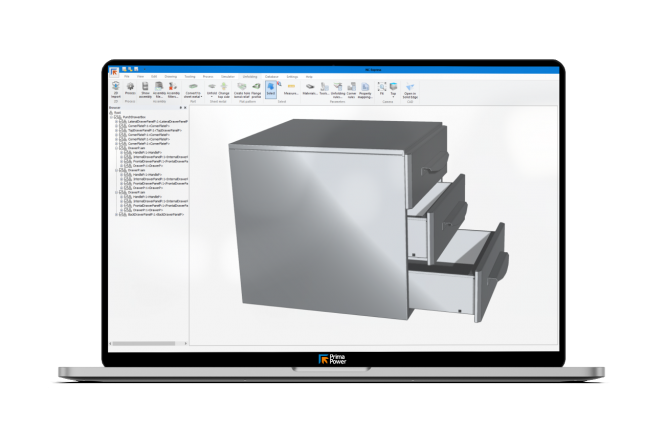

- Precise unfolding of 3D assemblies and single part models, creation of unfolded flat patterns either from an assembly or single part model

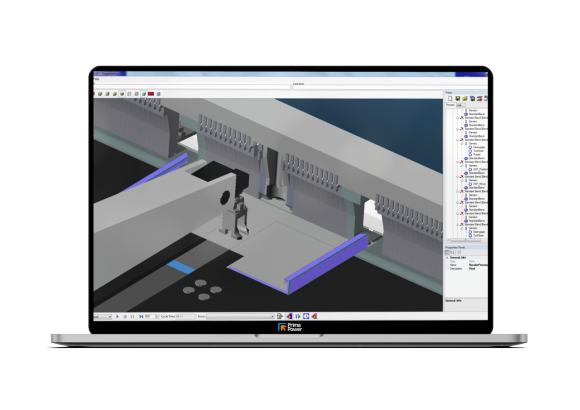

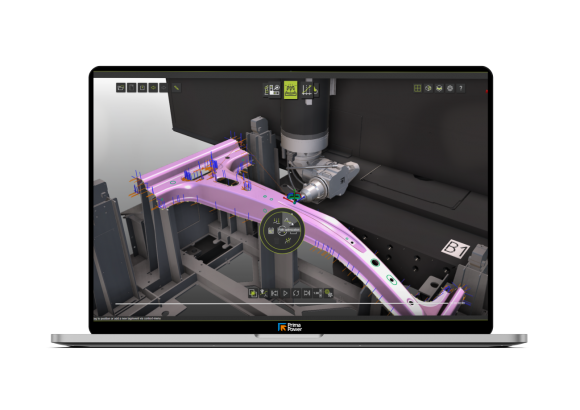

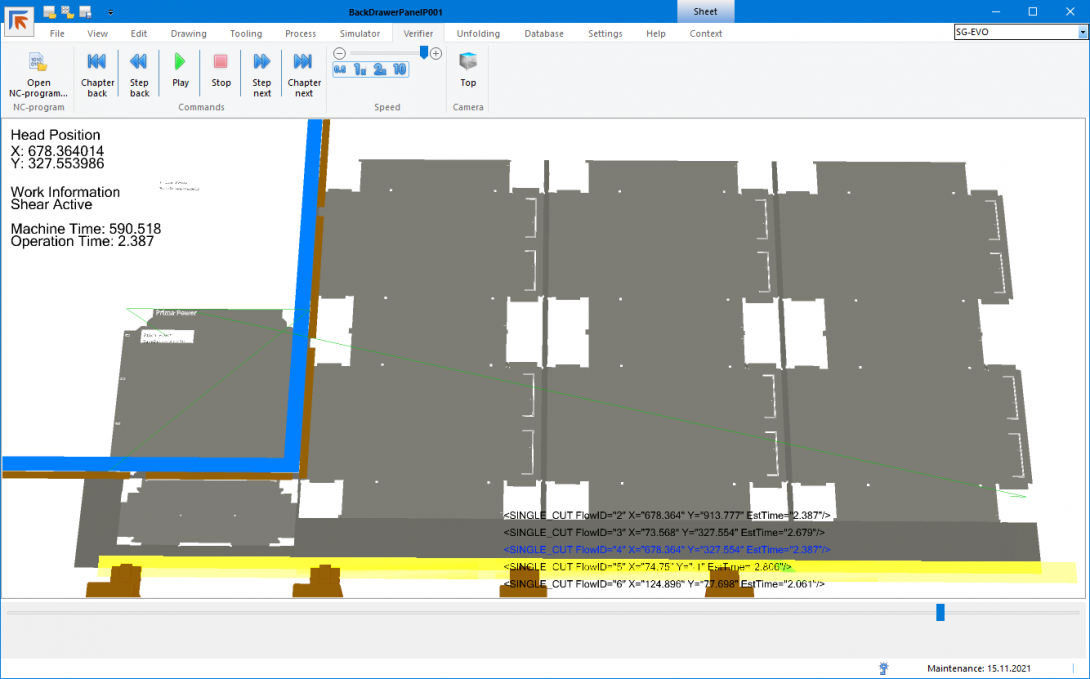

- Simulator: visual simulation helps to verify that cutting and punching sequence is optimal, the same simulation run at the machine’s to guarantee the reliability and full compatibility of the NC program

Unfolding

An extensive range of native 3D-file importers makes easy to read 3D-models from various CAD programs. Precise unfolded flat patterns are created either from an assembly or a single part model. Flat pattern holds all necessary information for further processing either on a punch, a laser or a shearing machine.

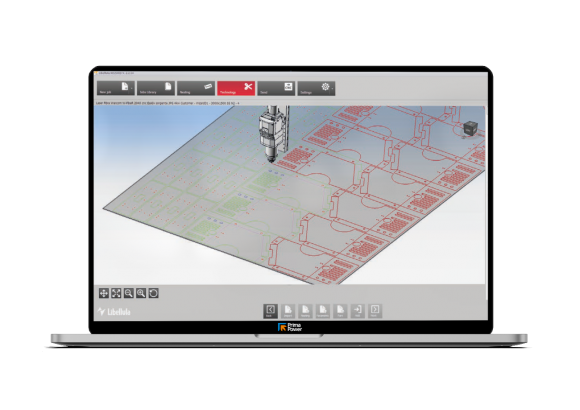

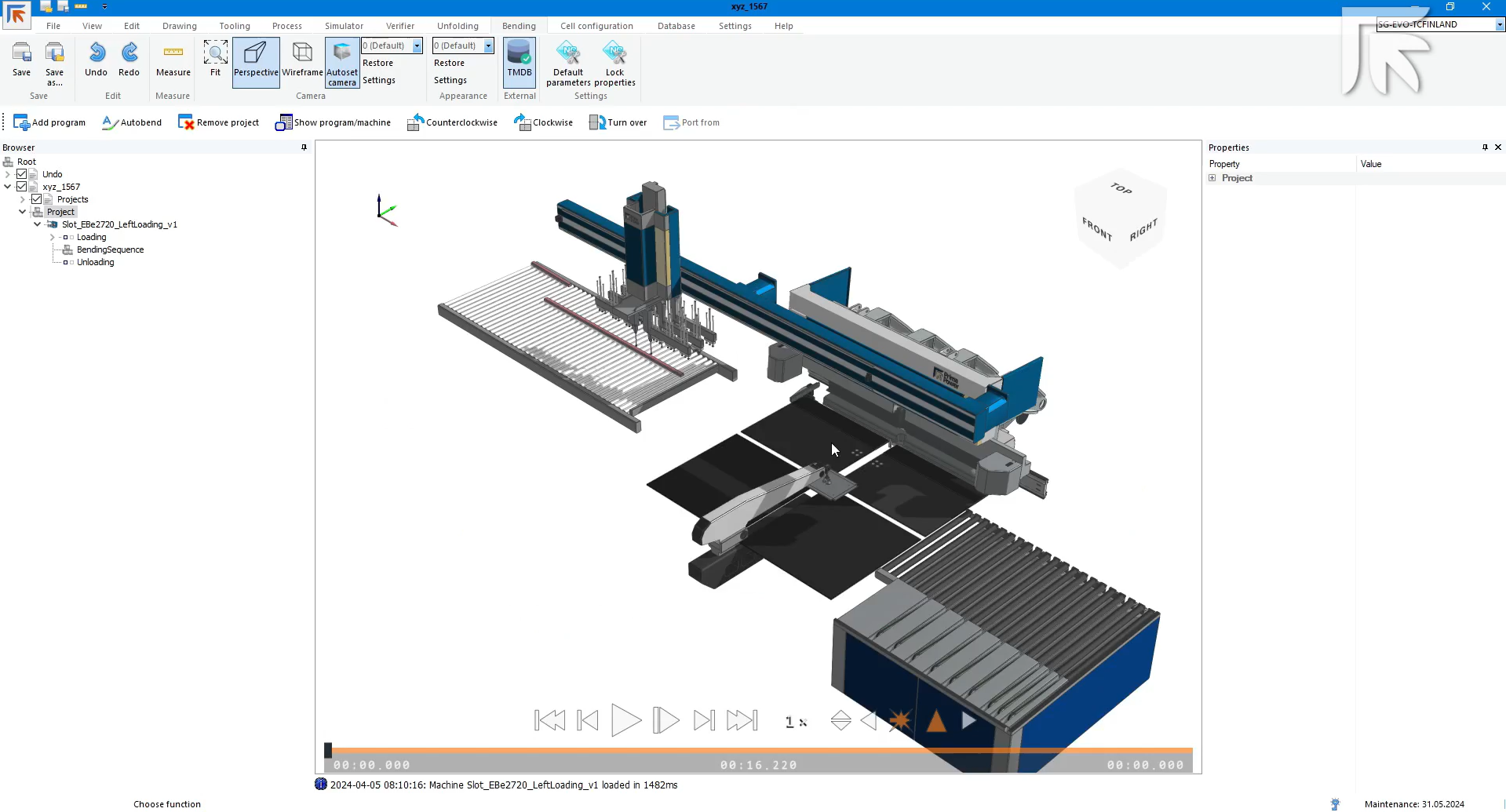

Automated programming

NC Express supports automatic programming from CAD model and ERP order data to NC-programs. It can automatically add laser cuts and punch hits to geometry files or use scripts for parametric parts. Through the order database you can import order data, nest them to sheets, optimize and postprocess to NC-programs.

Automatic nesting for punching, shearing and laser cutting

NC Express comes with a powerful nesting module for free-form and sheared parts.

Automatic nesting saves your work time and brings material consumption down.

Automatic part sorting for automated system

Integrated automatic tooling process adds a robot gripper placement based on part geometry, punching and forming hits and part weight.

Reliability, efficiency and speed in production

NC Express is designed ground up to get the best performance from Prima Power machines. New features on machines are first implemented using NC Express, which assures fluent and efficient operation. Prima Power expertise over the years is used to fine-tune all aspects for reliable every day production.

Automatic machine sequence optimization

Motion sequence overall has a considerable impact on machine performance in terms of reliability and speed. NC Express is designed to get the best performance from Prima Power machines.

Take a look at the other products and choose the best solution

Master BendCam

MACHINE PROGRAMMING

Efficient managing of Prima Power bending machines through interactive graphical techniques

AutoPol BendSim

MACHINE PROGRAMMING

Easy-to-use and effective tool for off-line programming of all Prima Power P series brakes.

Wizard

MACHINE PROGRAMMING

Revolutionary CAM application, Nesting, technology, and machine code in 4 steps to combine ease of use and quick machine preparation.

Prima Power 3D CAM

MACHINE PROGRAMMING