Application Group

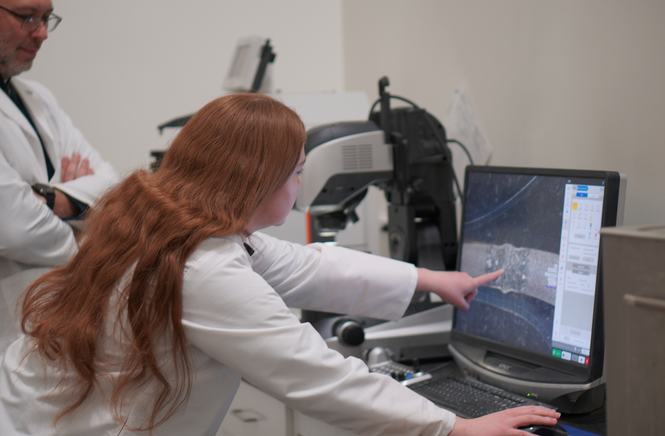

At LASERDYNE, we prioritize our customers' success throughout the entire lifecycle of our machines. From purchase to the end, we are dedicated to supporting them through challenges such as workforce reductions and ensuring machine availability and future preparedness. We invest additional resources in enhancing the LASERDYNE Application Group™ to facilitate seamless progress in customer-specific projects and resolve production challenges, promoting continuous improvements.

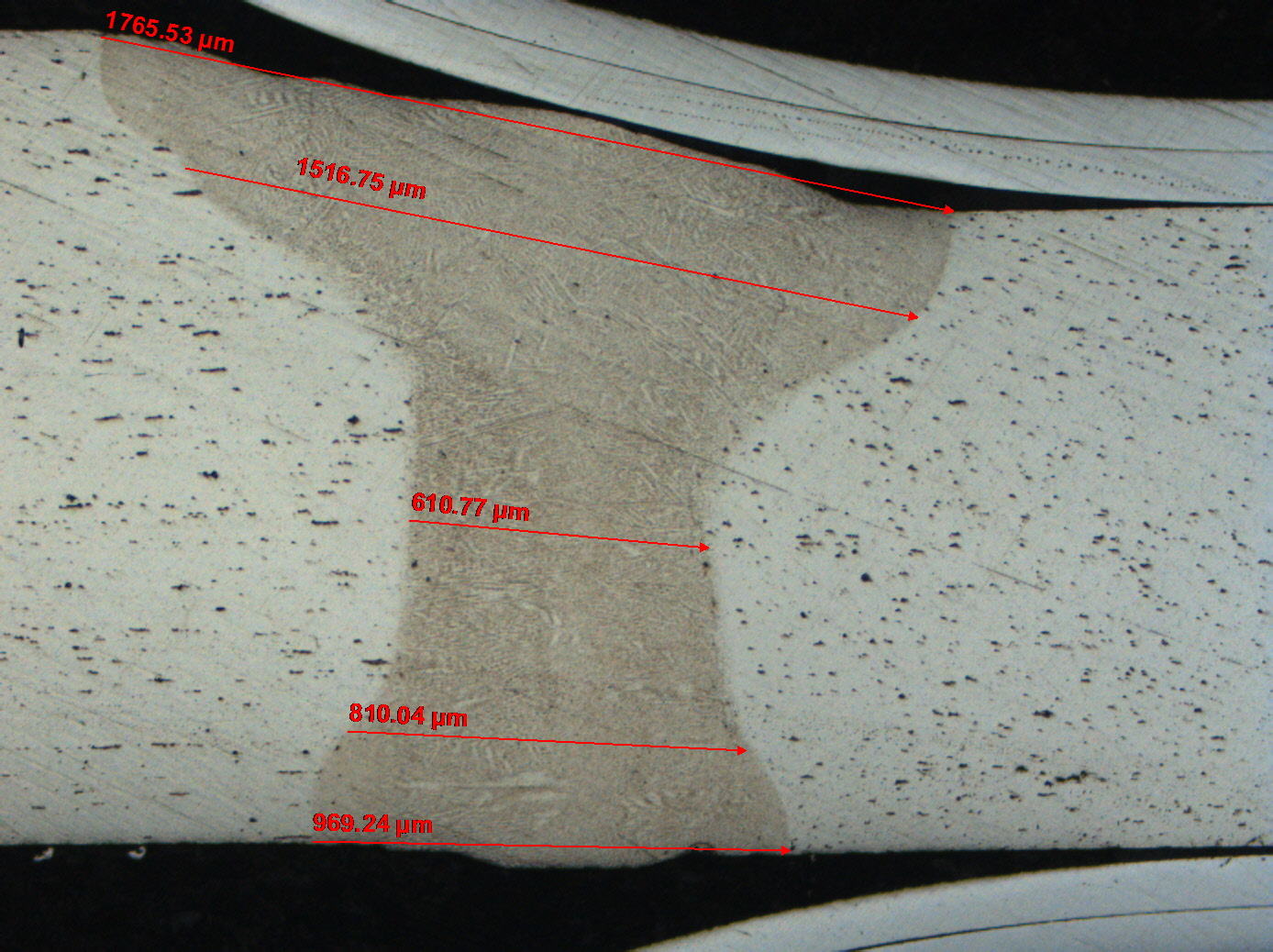

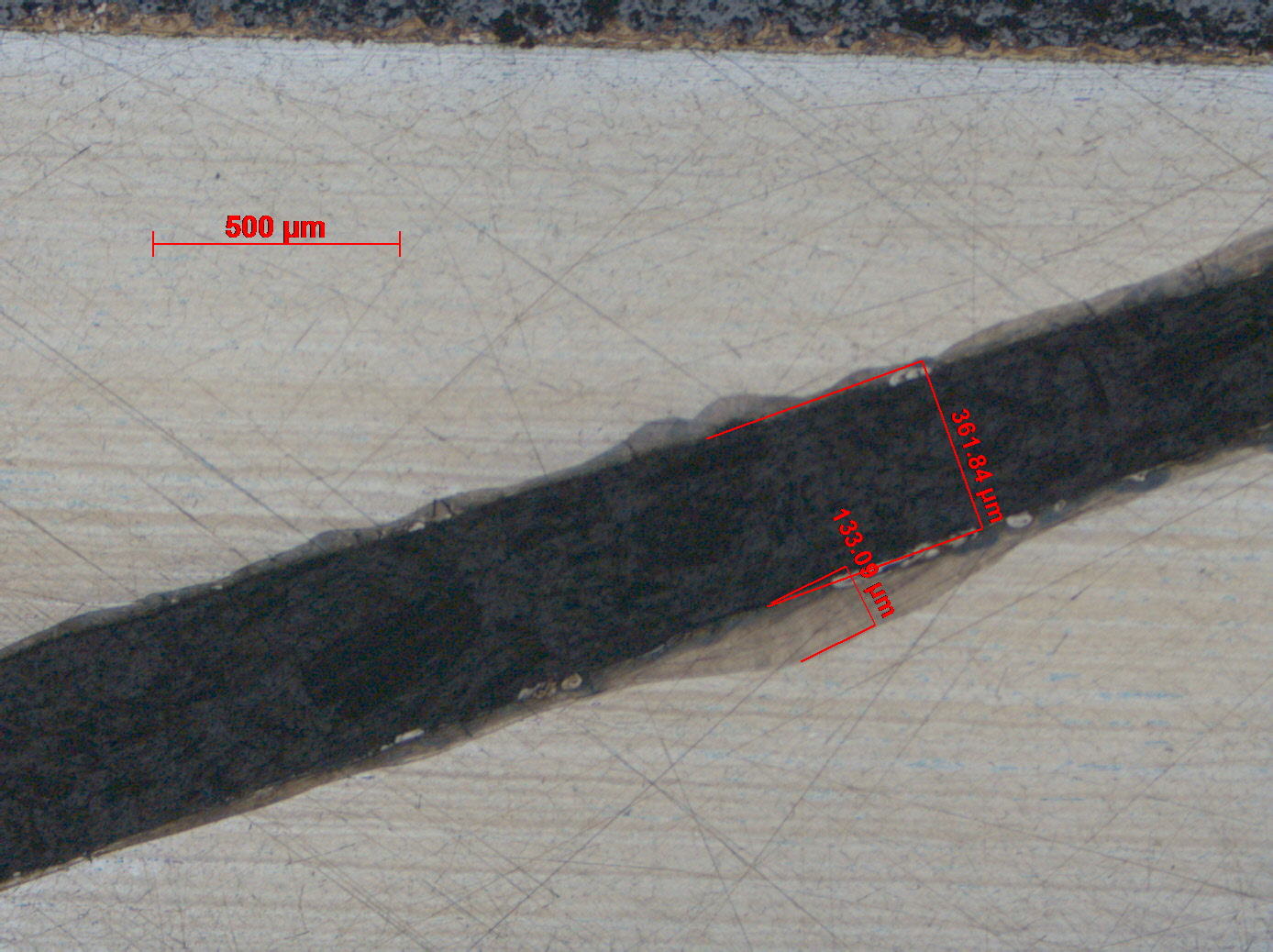

The LASERDYNE Application Group meticulously examines the metallurgical outcomes of laser welding, drilling, and cutting processes. Through thorough inspection of micrographs of the workpiece, our team ensures that the results not only meet but surpass specified requirements.

In line with our commitment to technology and innovation, Prima Power LASERDYNE is actively working to streamline Laser Application Development, minimizing the time and energy required. Our comprehensive services include:

• Develop laser processes for welding, drilling, and cutting

• Create part programs for LASERDYNE systems

• Test laser processing coupons and inspect micrographs

• Design efficient workpiece fixturing with quality checks

• Review and optimize existing programs

• Conduct Design of Experiments for materials and processes precision

• Explore laser applications on non-traditional materials

• Analyze and implement improvements for optimized performance in existing processes

LASERDYNE®

LASERDYNE®

STORIES OF EVOLUTION

Lasercraft USA Knows 5-Axis Laser Cutting Backed By 30 Years Experience And The Latest Technology -- Success Grows Using A Newly Acquired LASERDYNE® 430 With BeamDirector®

Expertise in integration

Customer-focused approach

High-speed flexible solutions

An integrated and pragmatic committment.

We operate all over the world: find the Prima Power office closest to you and contact us.

© PRIMA INDUSTRIE S.p.A., single-member company | Via Torino-Pianezza, 36 - 10093 COLLEGNO (TO) ITALIA | Share Capital €26.208.185 | VAT 03736080015 - C.C.I.A.A. Torino 582421 | Reg. Impr. Torino n. 03736080015