Prima Power in the domestic appliances sector

Find out what we do in the domestic appliances sector

Given the variety of product models available that can be made in every shape, size, and design, there is a growing need to tailor products specifically to the needs of the customer. In addition, the growing trend of simplifying the daily user’s life with smartphone level technology being applied also to white goods, translates to a greater variety of functions and customizations. Undoubtedly, there is a need for extremely flexible and dynamic systems that can meet even the most stringent aesthetic standards. Traditionally, stainless steel is used because it combines durable quality with low maintenance. The combined need for maximum quality and short deadlines therefore requires ultramodern production tools.

Our products are typically used to manufacture refrigerator doors and panels, ovens and cookers, sinks, kitchen hoods, cabinets, commercial kitchens, buffet systems, self-service systems for hotels and canteens, and stoves.

Our machines are designed to perfectly respond to the characteristics of the domestic and commercial appliances sector: large volume batches, high productivity and a growing demand for automation. Another distinctive feature is the variety of production of products with various shapes, designs, and customizations.

Part thickness and dimensions can vary from medium to small and the processed components have high aesthetic standards, which require the use of stainless steels which are pre-painted, super mirrored etc.

EXPERIENCE

We meet the needs of the white goods and commercial industry.

LISTENING

We customize our machines to your actual needs.

FLEXIBILITY

You can create designer components without compromising productivity

Solutions

Find your ideal solution

Our systems offer great flexibility in every process. This allows easy customisation of finished products and greater freedom in creating designer products without compromising productivity:

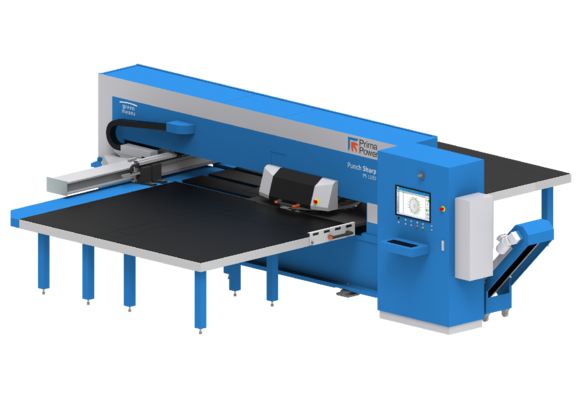

- punching machines with high-capacity tool turrets reduce setup time

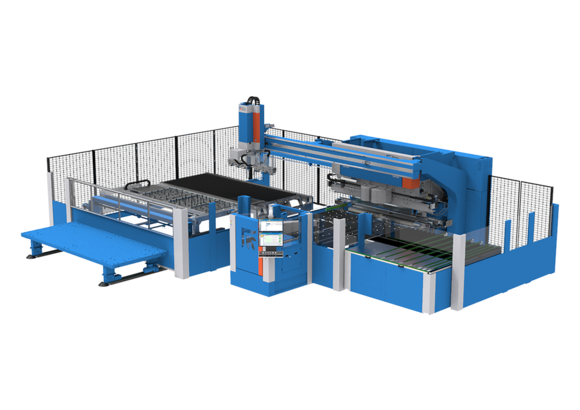

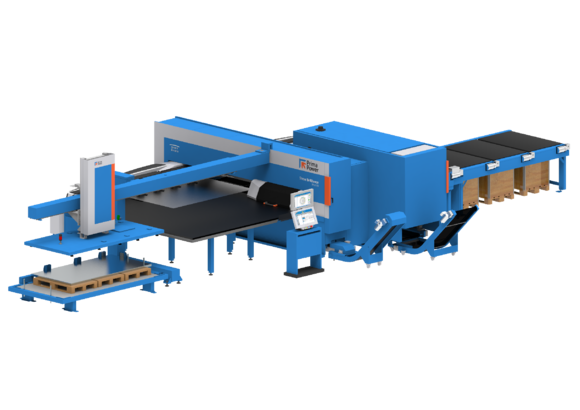

- combined punching/shearing or punching/laser systems give the best of both processes in a single machine

- 2D and 3D laser machines with extreme versatility of the laser in terms of shapes, profiles and material thicknesses

- panel benders and press brakes complete the finished components thanks to their ability to perform complex bending profiles.

Our systems guarantee high precision and repeatability in punching, shearing, bending and laser cutting, as well as an excellent surface quality of the finished component.

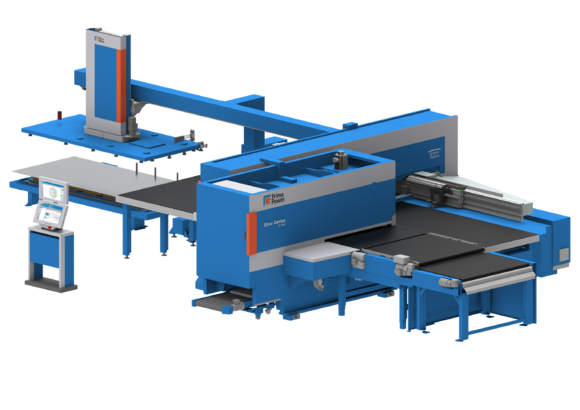

Our combined punching right-angle shearing systems are particularly efficient for producing square or rectangular shaped components.

Our wide range of manual, semi-automatic and automatic bending machines cover all your bending needs in terms of flexibility, productivity, profile complexity and material thickness.

We understand the geometries of domestic appliances are becoming more and more complex. This means the laser, with its unrivalled versatility, is the most suitable tool to meet these new design requirements. Our range of flat bed laser machines and combined punching-laser systems is one of the most vast on the market.

We can provide you with various levels of automation, including the most sophisticated and factory-wide flexible manufacturing systems to ensure maximum productivity and efficiency. Our automation modules can be integrated gradually, according to your current and future needs.

Our professional services complement our advanced technology and are the key to improved productivity and higher profit.

All our systems are designed and developed based on the "Green Means concept": they are productive and eco-sustainable at the same time.

Application examples

Behind every component this is a Prima Power machine

- doors and panels for refrigerators, ovens, washing machines, dishwashers

- kitchen hobs

- kitchen hoods

Related technologies

Browse our technologies to choose your machine

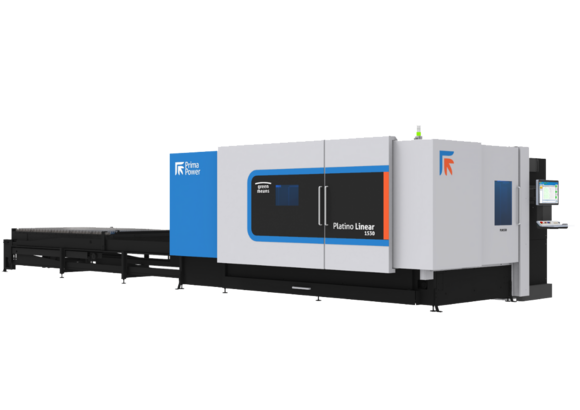

Platino Linear

2D LASER CUTTING MACHINE

The reliable and productive solution for cost-effective 2D laser processing

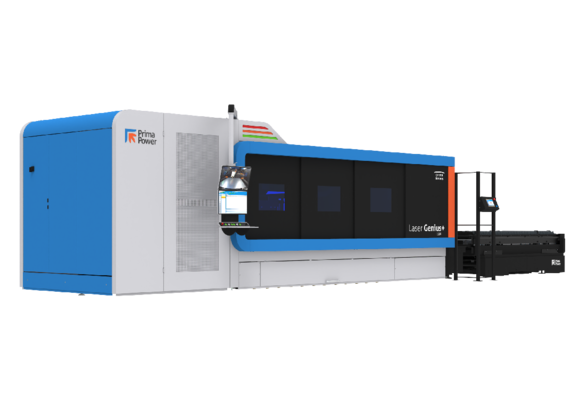

Laser Genius+

2D LASER CUTTING MACHINES

Prima Power laser machine faster, more precise, cheaper, for larger and heavier pieces.

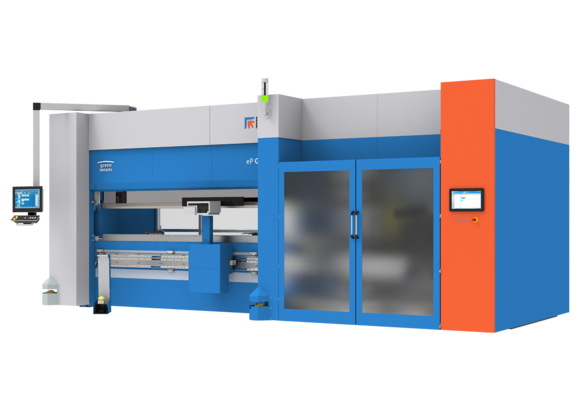

eP Genius

PRESS BRAKES

Efficient servo-electric bending solution with a fast and automatic tools change storage

FBe Fast Bend

PANEL BENDERS

The answer to multiple applications. Semi-automatic bending solution for simple, flexible and accessible production

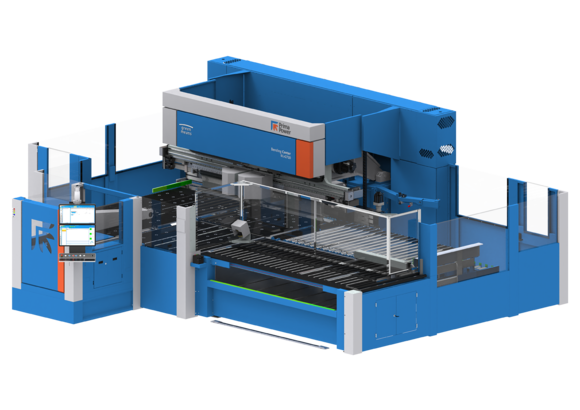

BCe Bending Centre

PANEL BENDERS

Flexibility at your service semi automatic panel bender combining flexibility and productivity

Punch Genius

PUNCHING MACHINES

Outstanding energy efficiency, low maintenance requirement and a high speed of operation.

Shear Genius

PUNCHING AND SHEARING COMBINED MACHINES

Highest productivity with integrated punching and shearing

STORIES OF EVOLUTION

Find out how Prima Power technology has contributed to the success of a company in the Domestic appliances sector.

Astra | Order and efficiency drive productivity, from first cut to finished product

Astra was founded just short of thirty years ago as the result of an innovative instinct which proved successful in just a few years: that stainless steel would become the technological material of the future.

Future fit with the punch laser machine

Eisenwerk Wittigsthal GmbH invests in a punch-laser system so as to be ready for the digital future.