eP Genius

PRESS BRAKES

Efficient servo-electric bending solution with a fast and automatic tools change storage

READY TO PRODUCE

Thanks to the automatic tools change, the machine is always ready to produce.

ACCURATE

Reduced possibility of human mistakes caused by manual tool change and set-up.

FLEXIBLE

Programming and production of kit, as well as of small production batches.

USER FRIENDLY

Easy to install, use and maintain.

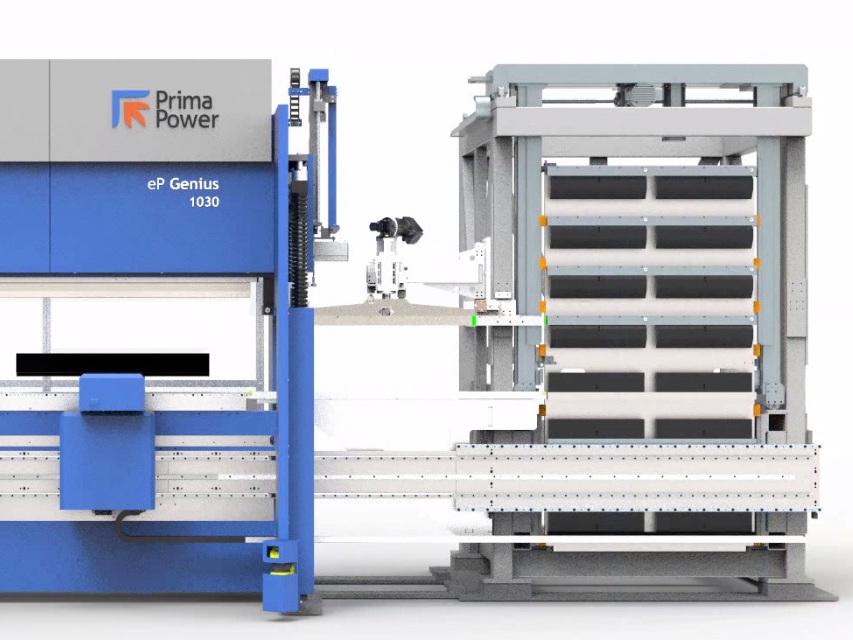

eP Genius 1030

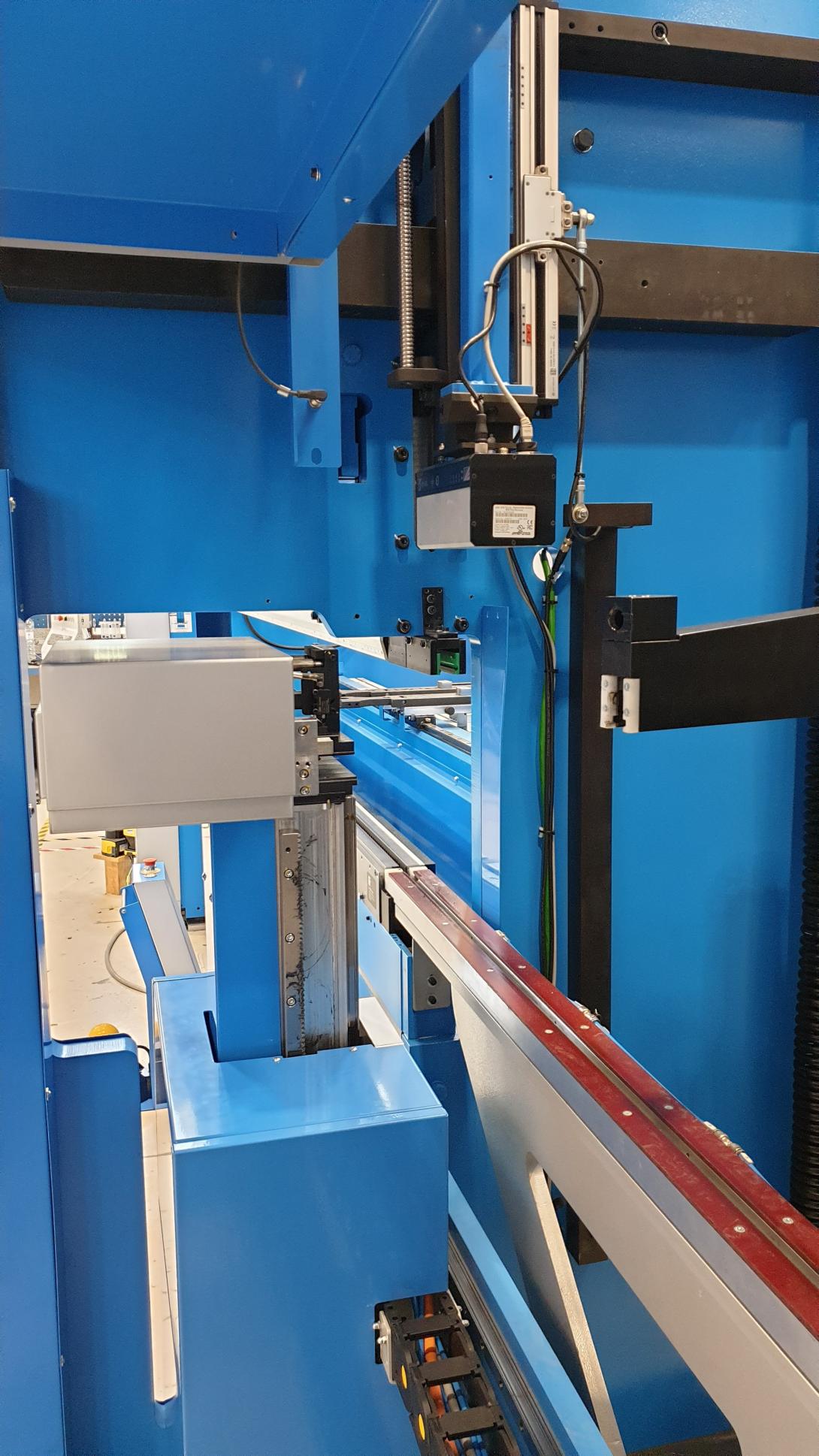

Prima Power eP Genius 1030 consists in the integration of the servo-electric eP-1030 with one automatic tool change storage.

This concept offers a more versatile, faster and reliable bending solution, which eliminates the manual set-up of the machine, and allows the operator to commit his time and skills to the preparation of bending batches.

eP Genius is the ideal solution for minimum batches where it is possible to estimate the machine set-up, and short cycle times help you gaining higher market competitiveness.

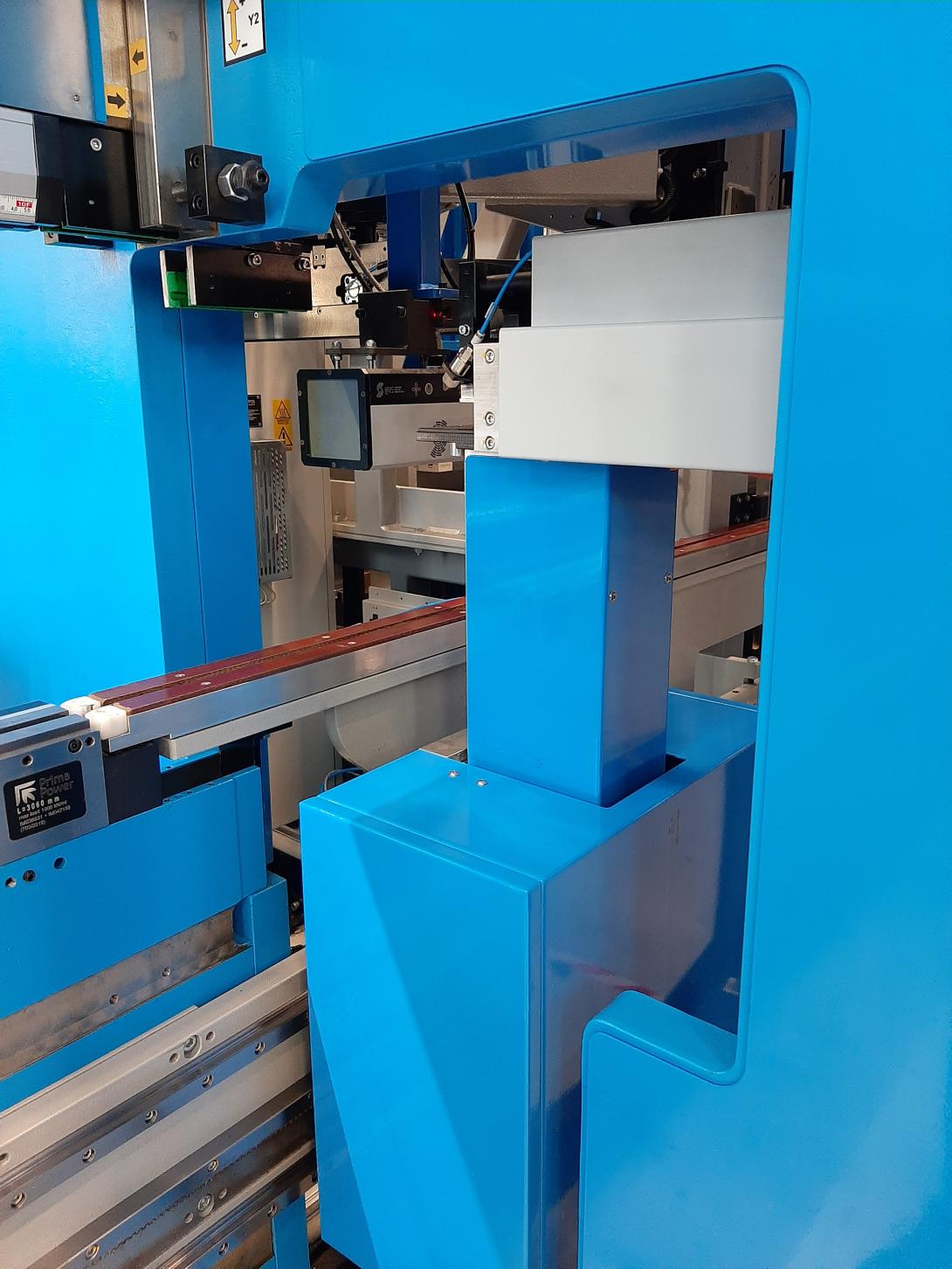

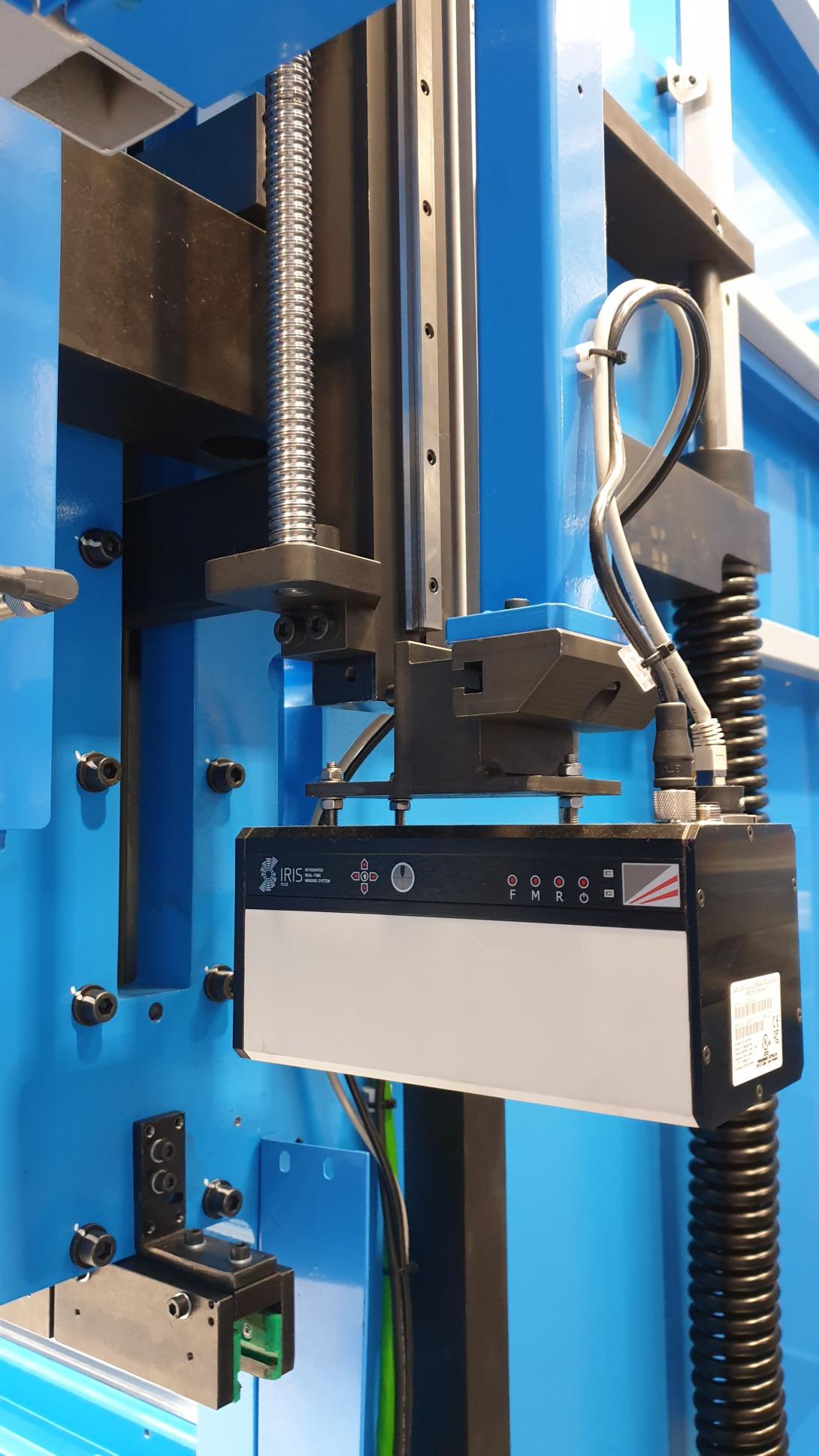

During the tool change, a safety laser scanner detects the working area and protects the operator without need for human intervention when it's time to reset the machine functionalities.

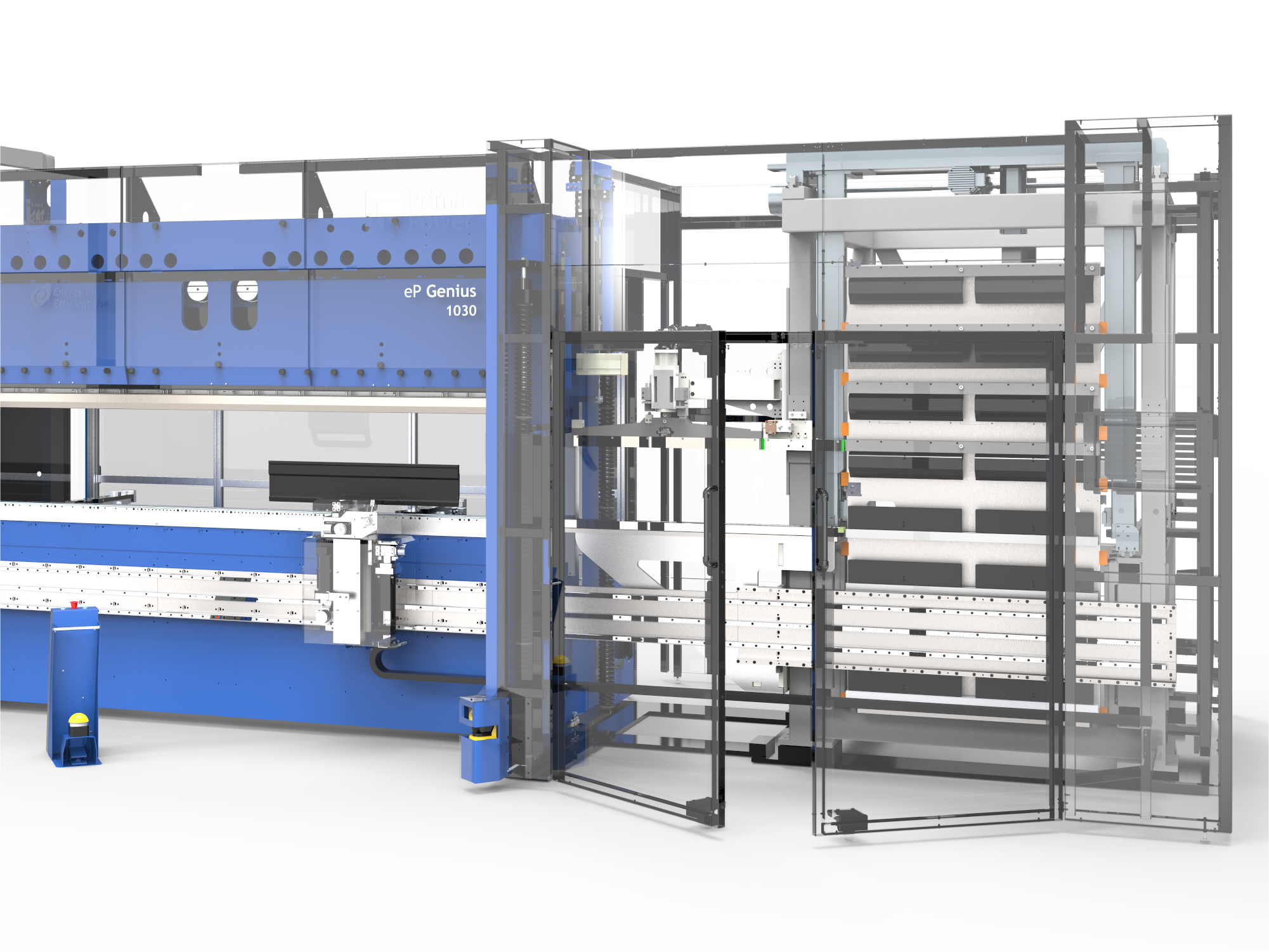

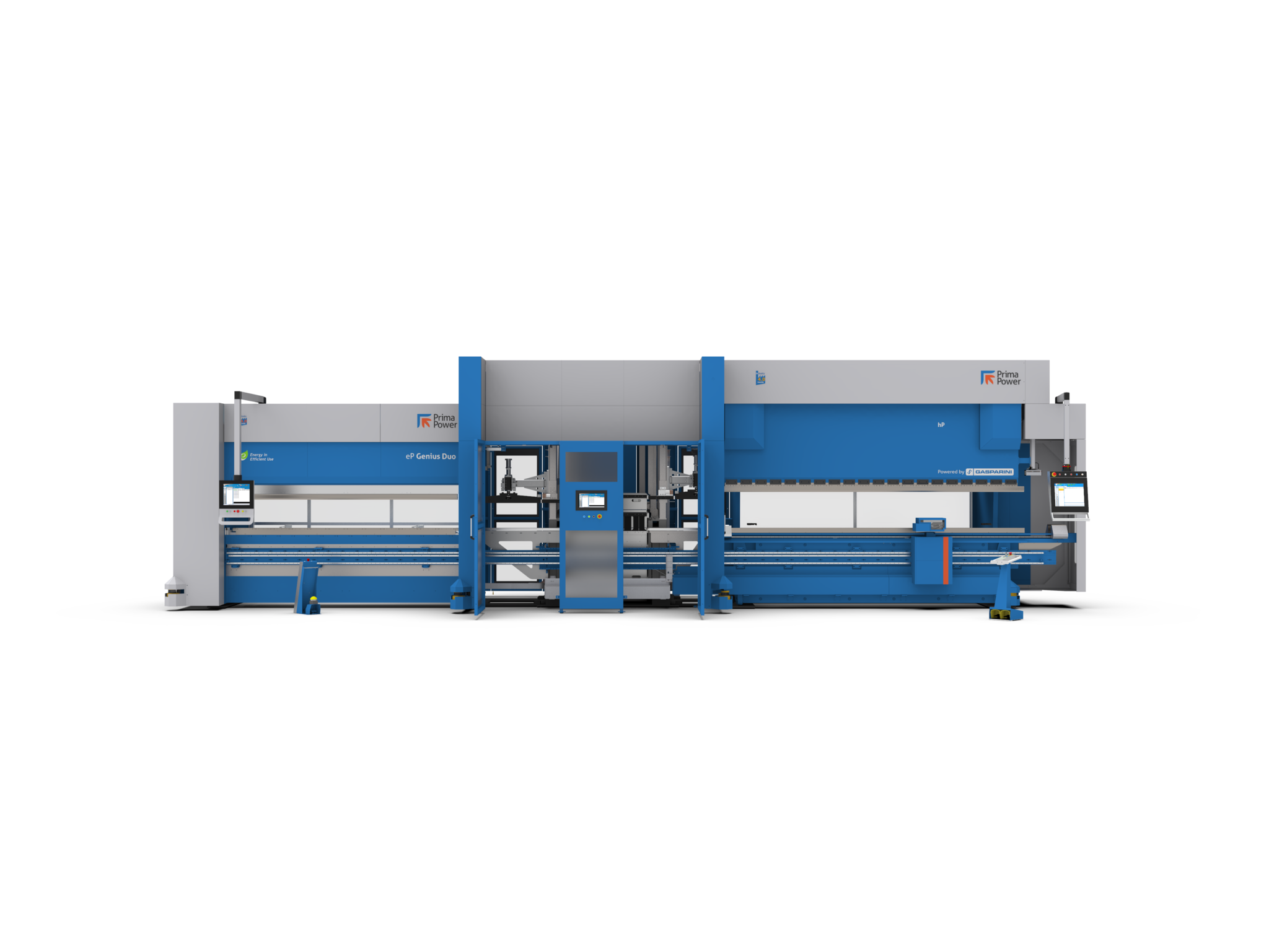

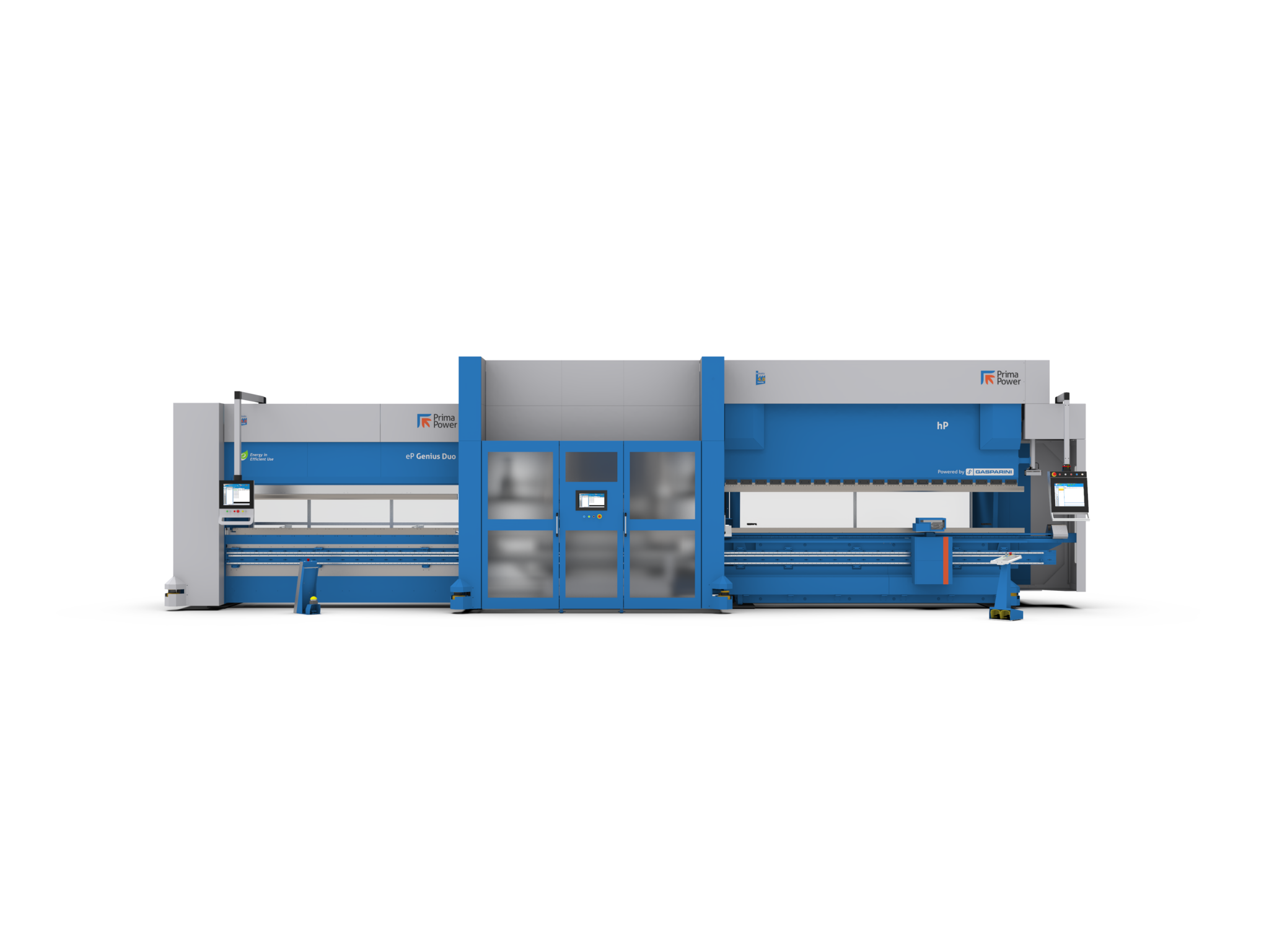

eP Genius Duo

The unicity of this bending solution is the combination of the two press brakes and one automatic tools storage that can manage the two machines at the time.

The real innovation of this configuration compared with the standard eP Genius 1030, it's the possibility to choose a different press brake for the left side, and to add a second press brake on the right side. The second machine on the right can be a servo-electric eP-1336, or an hydraulic hP machine (to be selected among specific sizes).

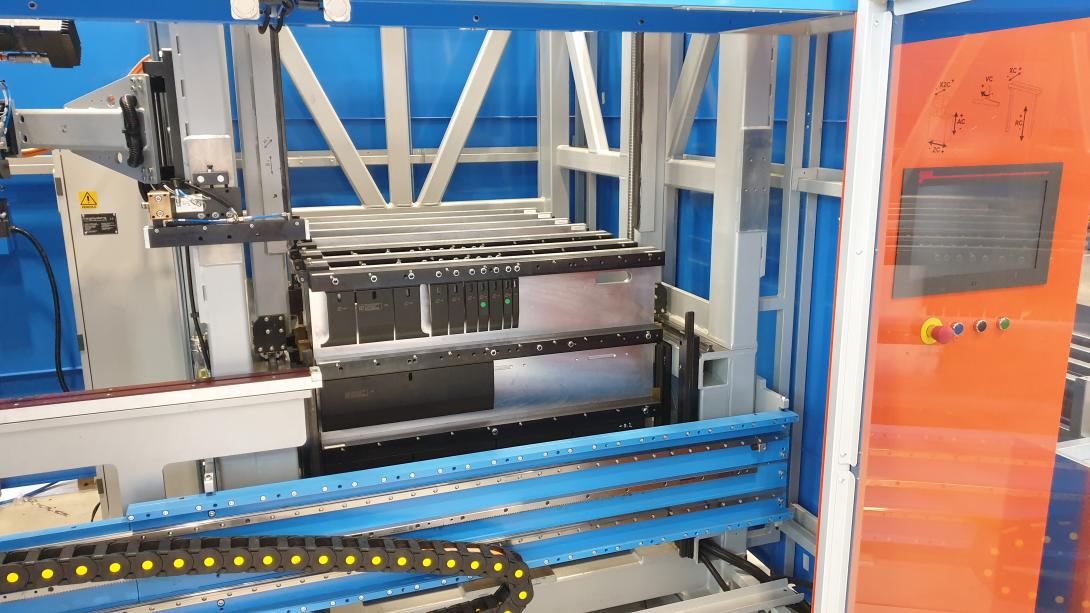

The Duo configuration can count on a 32 up to a 60-meters of tools capacity, and a fast tools-holder shuttle that feeds both the machines, running from one side to the other.

The customer can get greater productivity with a rapid payback by bending materials of thin thicknesses on the eP while using greater thicknesses on the hP.

This gives our customers a wide range of opportunities and combinations creating the ideal machine they need to satisfy their production needs.

The eP-1030 included in the solution is the most versatile machine in the eP servo-electric range.

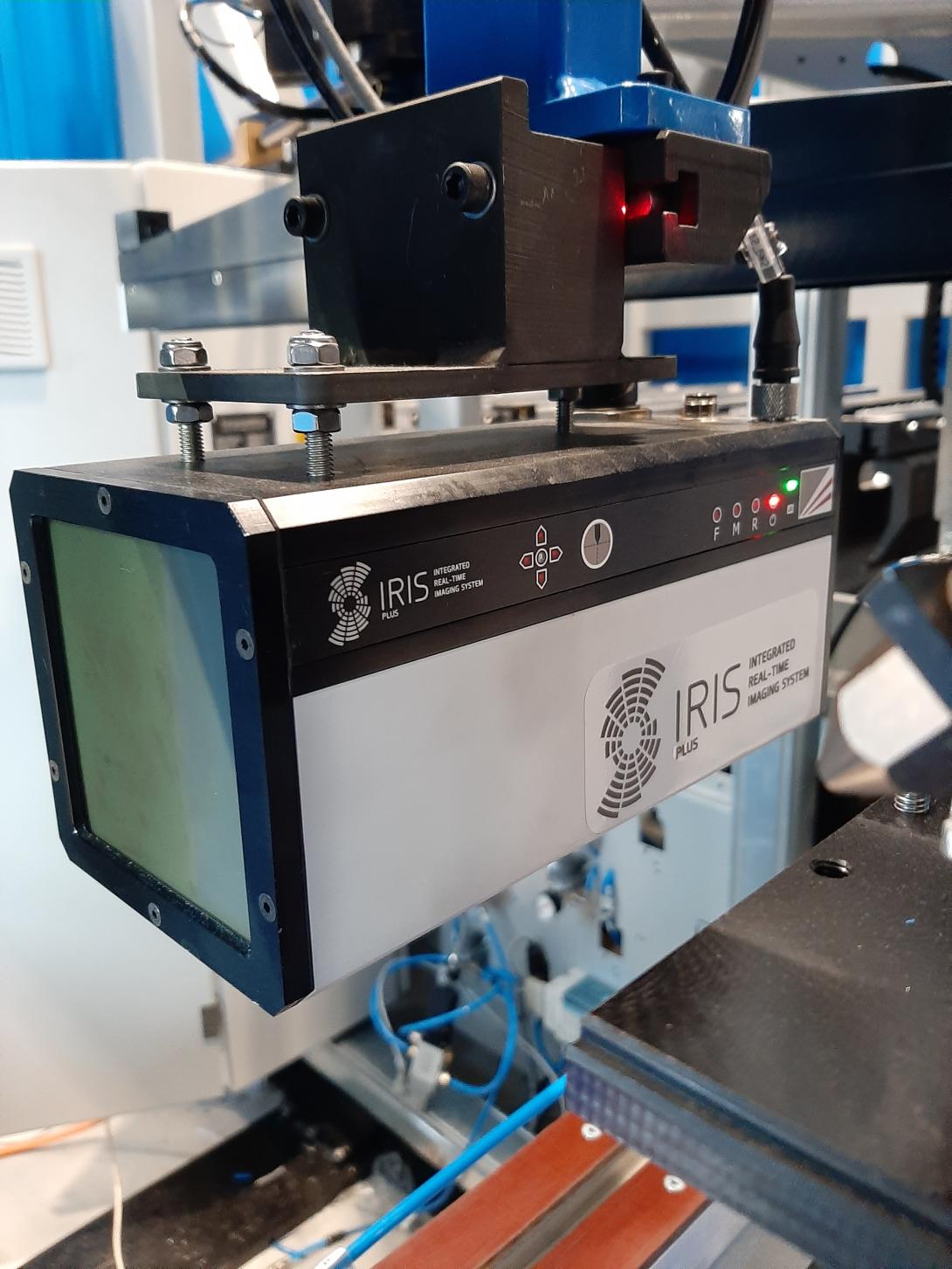

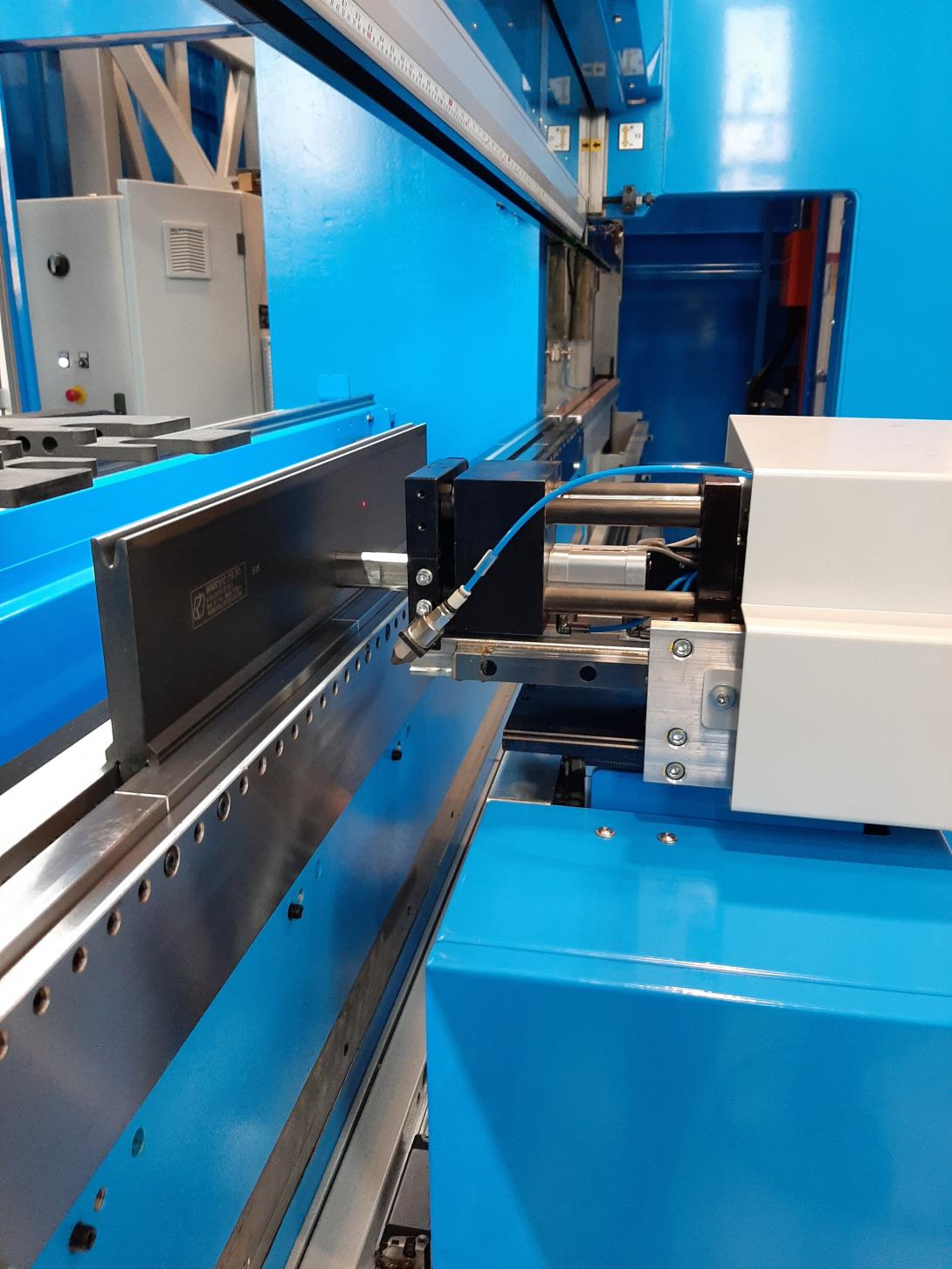

A perfect combination of tonnage (105 tons) and work capacity (3,060 mm of bending length), automatic CNC crowning, 5-axis back gauge and IRIS Plus angle control system on CNC-controlled motorized arms.

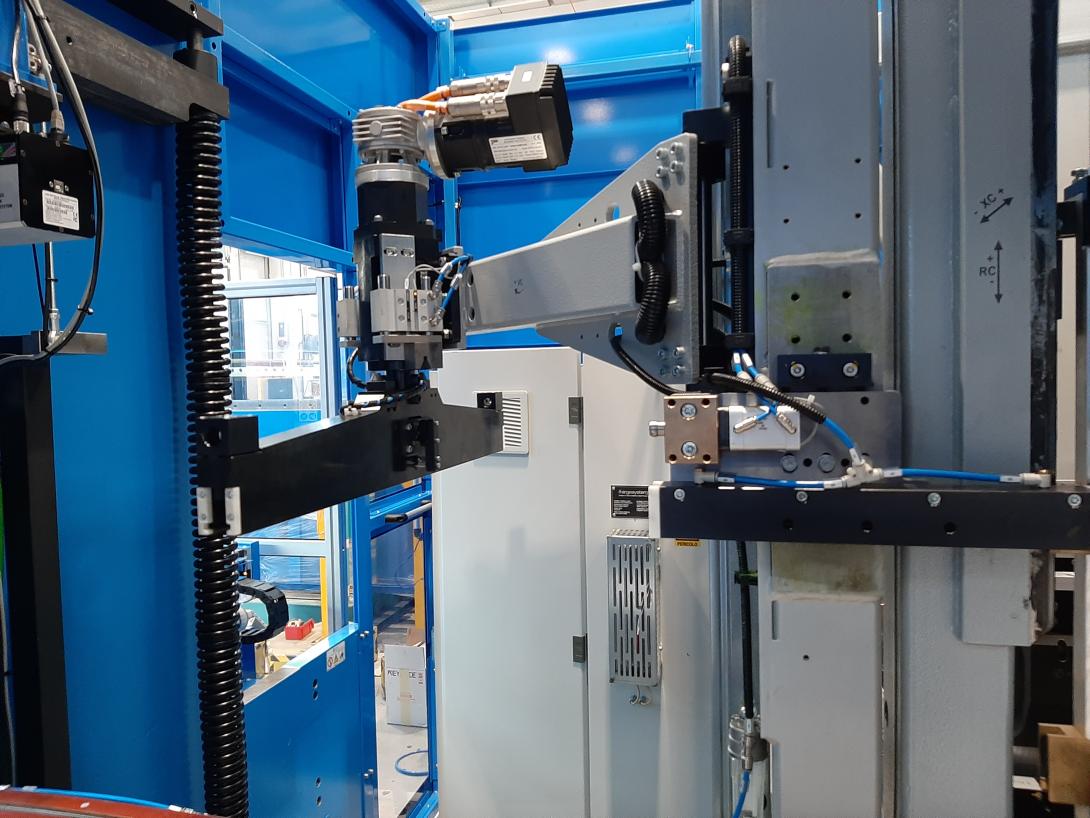

The tools storage, the main innovation of this product, can accommodate a total of 32 meters of tools to be placed on 8 tool-holder supports that move on 3 axes. It can handle Wila-style tools with a minimum length of 20 mm up to 515 mm. Furthermore, a rotating turret rotates the tools taken from the storage to grant multiple processing possibilities.

The latest-generation HMI allows the programming of the workpiece in a simple and intuitive way, both on the machine and off-line, as well as automatic management of the machine set-up.

eP Technical Data

Max. tonnage: 1050 kN

Distance between side frames: 3150 mm

Tools Storage Technical Data

Max. capacity of tools storage: 32 m / 60 m

Min. tools length: 20 mm

Max. tools length: 515mm

Tools Shuttle speed: 2,600 mm/sec

Speed for tools overturn at 180°: 0.4 sec