Software

Product families

Level up your productivity with our digital ecosystem

- One comprehensive ecosystem for the entire production flow.

- Improved profitability with optimized material management and data-driven process and maintenance.

- Empower your team with enhanced programming capabilities combined with intuitive interfaces.

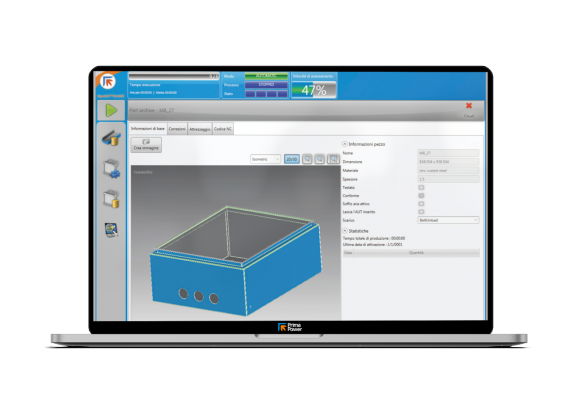

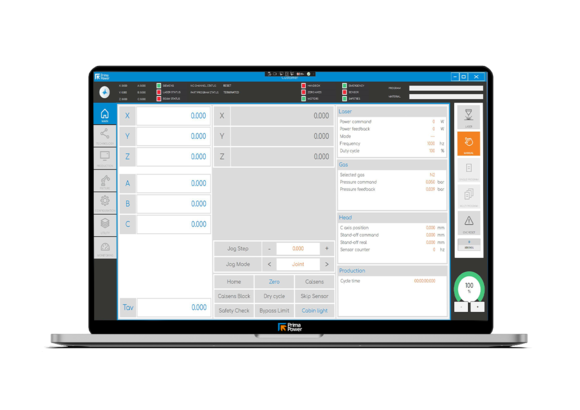

Always be in control of your system, regardless of the technology, with Prima Power’s complete suite of machine user interface software.

From controlling machine operations, tools, parameters, and production orders to the stacking of finished parts, all available directly on-board with an intuitive touch-screen interface.

ALL IN ONE

CONTINUOUS AND INTEGRATED PRODUCTION FLOW

| PLANPRODUCTION PLANNING Tulus® Office

Discover our Planning and Monitoring range!

|

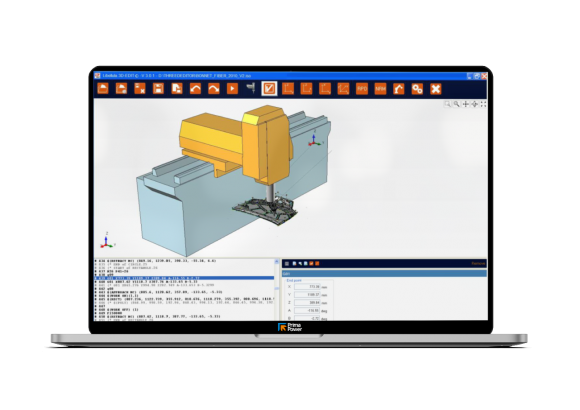

| PROGRAMCAD/CAM & SIMULATION NC Express

Discover our Machine programming range!

|

| RUNINTUITIVE INTERFACE Tulus®HMI

Discover our H.M.I. product range!

|

| CONTROLMONITORING & REPORTING Tulus® Office

Discover our Planning and Monitoring range!

|

| TRUSTSECURE DATA-DRIVEN SERVICE Tulus® Analytics

|

Choose the perfect Software for you

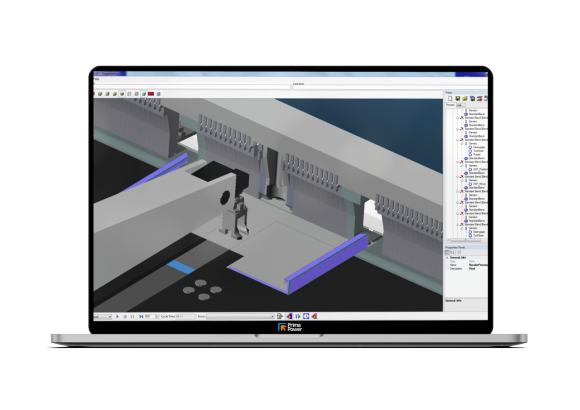

Tulus Cell

H.M.I.

Integrated and scalable software family for centralized management of fabrication.

Tulus Visual Monitoring

H.M.I.

Web-based application for machine operators that brings information transparency on the current manufacturing line status

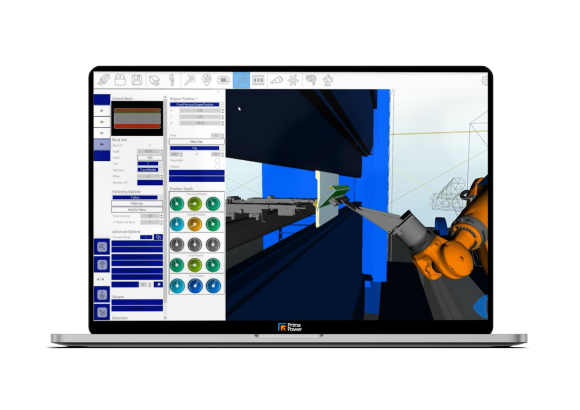

Tul-Robot

H.M.I.

The operator interface that allows managing the system and the part programs during the production phase.

2D Editor

H.M.I.

A precise and efficient cutting depends on a correct post-processor.

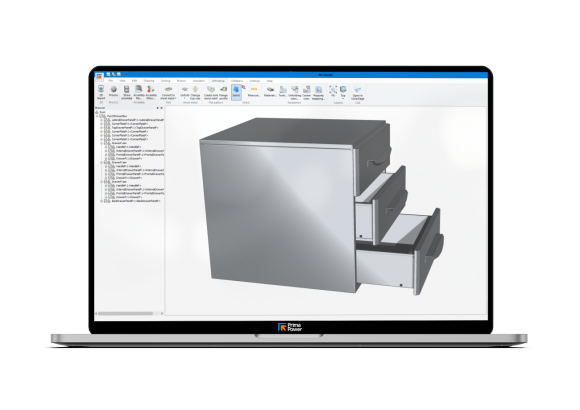

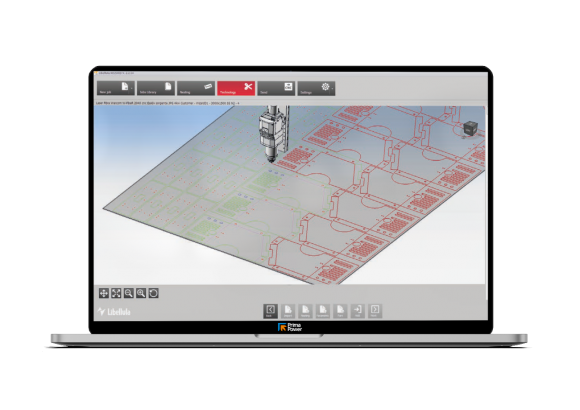

NC Express

MACHINE PROGRAMMING

Scalable CAD/CAM application that can be used for single part processing or as fully automatic batch processing software.

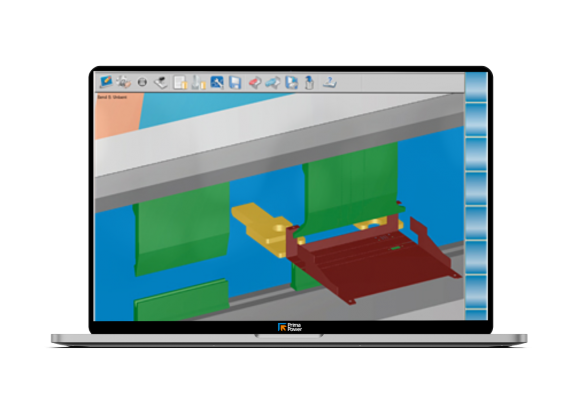

Master BendCam

MACHINE PROGRAMMING

Efficient managing of Prima Power bending machines through interactive graphical techniques

AutoPol BendSim

MACHINE PROGRAMMING

Easy-to-use and effective tool for off-line programming of all Prima Power P series brakes.

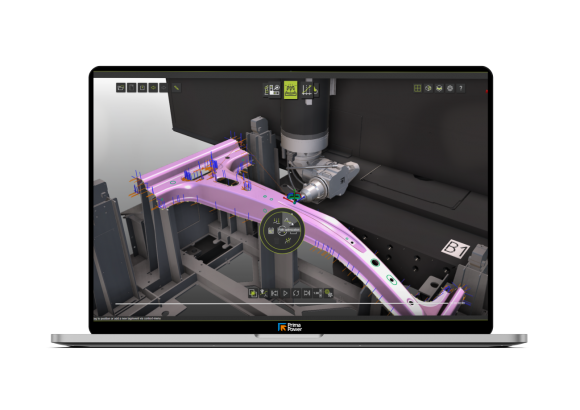

Prima Power 3D CAM

MACHINE PROGRAMMING

Cam application to program 3DLaser machine, provided by partner CENIT, in 3 license levels to support different use-cases

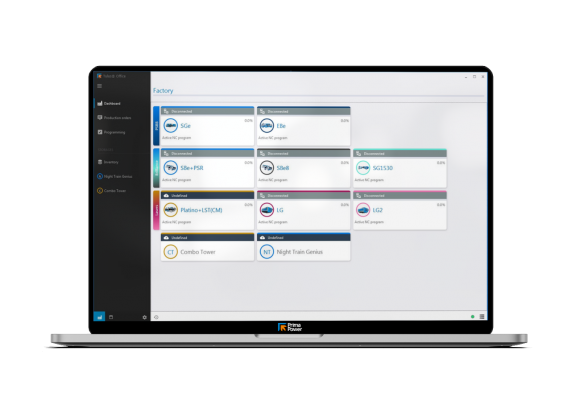

Tulus Office

PRODUCTION PLANNING

Work planning and controlling all machines in the factory.

Tulus Analytics

PRODUCTION REPORTING AND MONITORING

Parts production and machine performance reporting

Optia

OPTIA

OPTIA grants an extraordinary simplifying of sheet scraps recovery process.

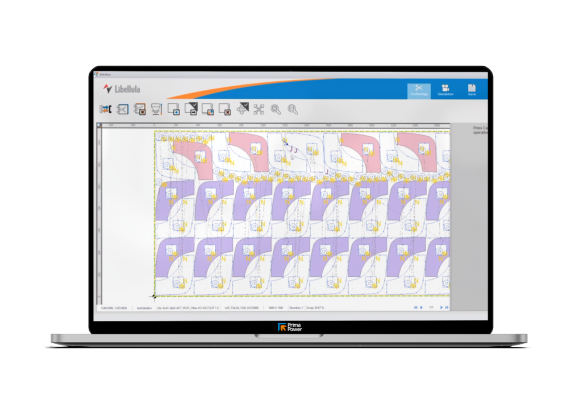

Wizard

MACHINE PROGRAMMING

Revolutionary CAM application, Nesting, technology, and machine code in 4 steps to combine ease of use and quick machine preparation.

Tulus Storage

H.M.I.

Software for Combo Tower Laser and Night Train is a touch-operated user interface with visual and modern look and feel.

Libellula.CUT Prima Edition

MACHINE PROGRAMMING