Prima Power machines are used in the industrial machinery sector because of their ability to process components with a larger gauge and size, while also responding to product customization needs, and can help the rapid recovery of economic activity after an equally sudden fall.

Prima Power in the Mechanics and machinery sector

Find out what we do in the Mechanics and machinery sector

The fundamental needs of the industrial machinery sector include the ability to process large components with a high thickness, to vary batches, to customize products, and to have the flexibility to make prototypes. These are all met by our machines.

In addition, there is increasing demand for the ability to operate systems in unmanned mode to increase their productivity.

EXPERIENCE

We’ve been aware of all the complexities of this sector for years.

LISTENING

We customise our machines to your actual needs.

EFFICIENCY

Our systems allow you to process different parts with a single machine.

Solutions

Find your ideal solution

Our products have been designed to offer flexibility: our punching machines can use a large range of tools, our integrated punching and shearing systems can machine even the most diverse parts with a single machine, and our laser machines allow you to cut very complex profiles.

Our products are suitable for both high volumes and small series productions, depending on your needs: avoid overproduction, reduce finished parts stock and obtain lean and "just in time" production.

Our efficient and versatile nesting programs enable maximum sheet metal utilisation, fast component separation and shorter cycle times.

The high quality of the parts produced with our machines eliminates the need for secondary machining, such as deburring or painting, and reduces assembly time.

All of our systems feature minimal set-up times and enable unattended “lights-out” production.

Our EBe6 panel bender can bend parts with a maximum length of 3,350 mm and a material gauge of 3 mm.

Our Laser Next 2141 3D laser machine can efficiently process large parts thanks to its very large working envelope.

The 2D laser machine Laser Genius+, available with laser power up to 15kW and size up to 2060, is the ideal solution for 2D laser processing in the field thanks to one of the best working range and maximum workpiece weight available on the market.

Our combined punching and laser solutions allow you to use multiple technologies with a single system, ensuring the highest quality and repeatability of the components produced.

Our wide range of automation modules enable highly efficient and flexible material flow and unattended production. These modules can also be added later, as budgets and production needs increase.

Our products allow us to produce responsibly: higher production of parts at a lower cost, whilst respecting the environment with the "Green Means" eco-sustainability approach.

Our services form an integral part of the product offering, and ensure maximum availability and utilization of the plant's production capacity, as well as enabling its future development.

Application examples

Behind each component there is a Prima Power machine

- All machine covers

Related technologies

Browse our technologies to choose your machine

FBe Fast Bend

PANEL BENDERS

The answer to multiple applications. Semi-automatic bending solution for simple, flexible and accessible production

BCe Bending Centre

PANEL BENDERS

Flexibility at your service semi automatic panel bender combining flexibility and productivity

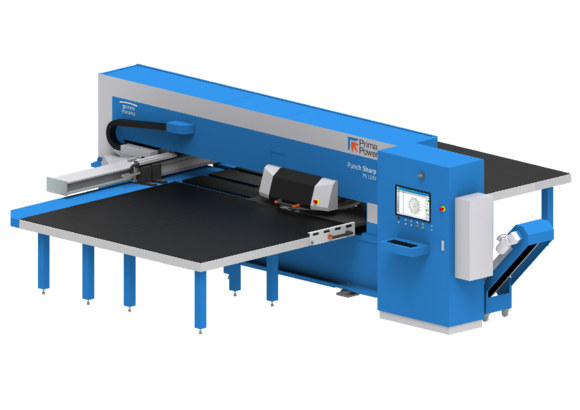

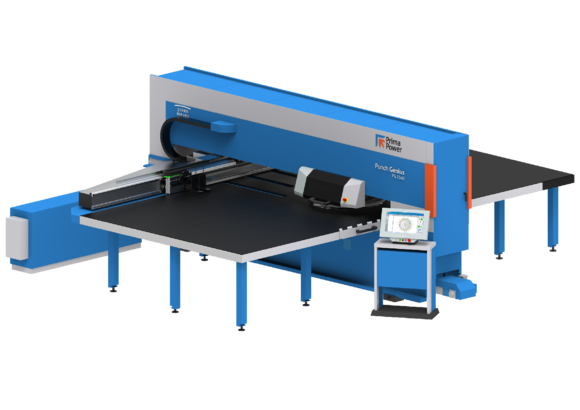

Punch Genius

PUNCHING MACHINES

Outstanding energy efficiency, low maintenance requirement and a high speed of operation.

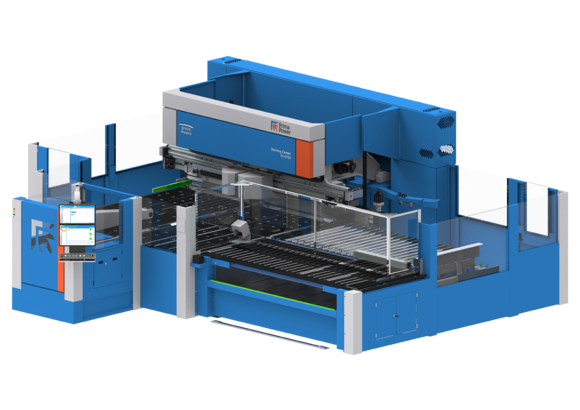

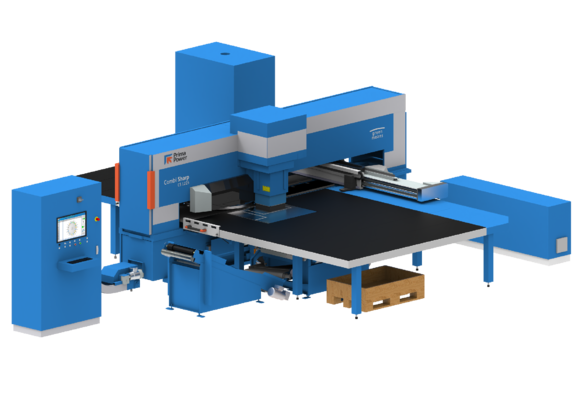

Combi Sharp

PUNCHING AND LASER CUTTING COMBINED MACHINES

Integrated punching and laser cutting at an affordable price

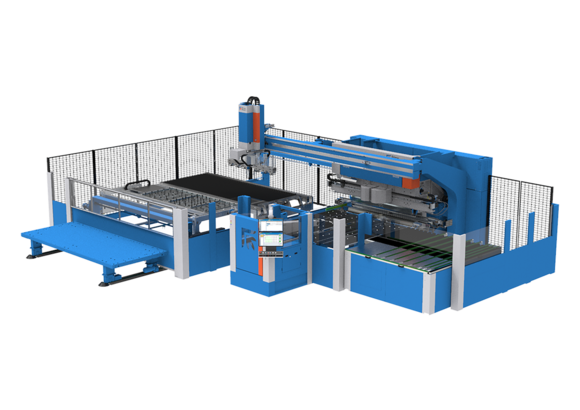

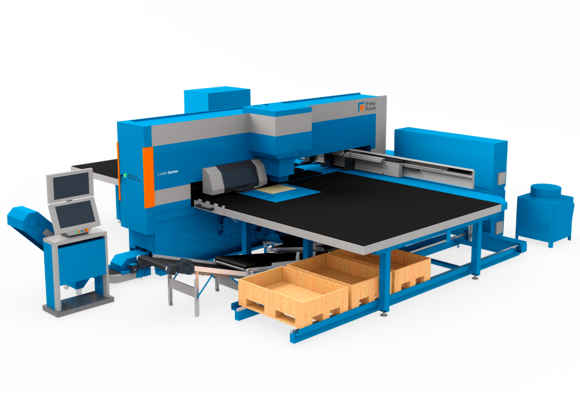

Combi Genius

PUNCHING AND LASER CUTTING COMBINED MACHINES

Punching + Laser cutting = Superior manufacturing economy

1+1>2

STORIES OF EVOLUTION

Find out how a Prima Power machine took part in a Mechanics and Machinery company's success

A&J precision sheetmetal | Silicon Valley Job Shop Achieves Success with Prima Power Machines

Since A & J Precision Sheetmetal Inc., San Jose, CA, first opened its doors in 1995, the company has earned a stellar reputation as a leading job shop producing high-quality precision parts in the demanding Silicon Valley.