Prima Power in the Electric cabinets sector

Find out what we do in the electric cabinets sector

Prima Power has specific knowledge in the electric cabinets industrial sector and can always offer a high standard of customization, along with the support of qualified experts from the design phase to technical support.

The main requirements in this sector are high productivity, even for small volume batches, and high quality components.

Products need to be tested and certified, so all systems used in the manufacturing process need to be accurate and repeatable. Furthermore, subsequent machining must be avoided to increase productivity.

The components produced are customised and have different dimensions and thicknesses: flexibility of the production systems is thus an important prerequisite. The main process consists in cutting the external profiles of the electric cabinet panels.

KNOWLEDGE

We are knowledgeable about all requirements needed in this sector.

LISTENING

We customise our machines to your actual needs.

EFFICIENCY

Several operations can be performed with a single machine.

Solutions

Find your ideal solution

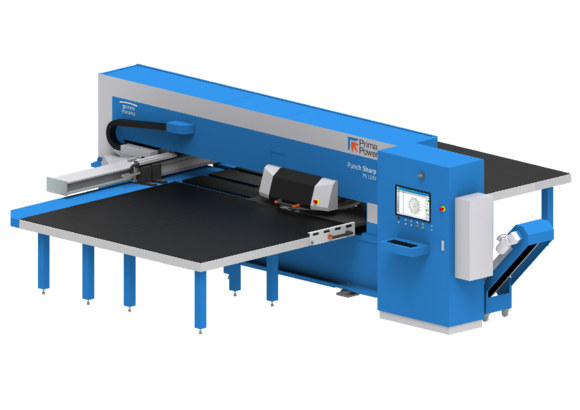

Our combined right angle punching-shearing systems are widely used to manufacture components for electric cabinets, as they considerably speed up the blanks cutting process. Subsequent bending operations are performed with press brakes or bending systems, which are also integrated with cutting systems in a complete work line. These are the main technologies used by electric cabinet manufacturers.

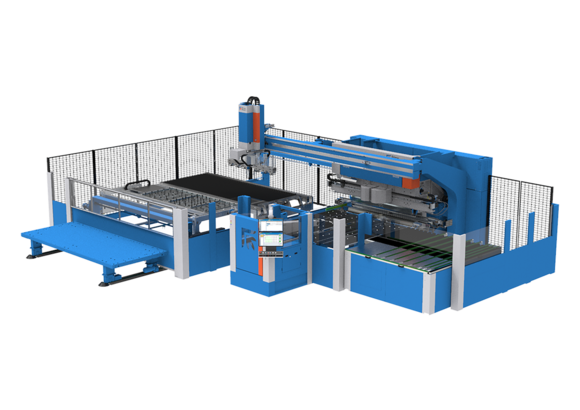

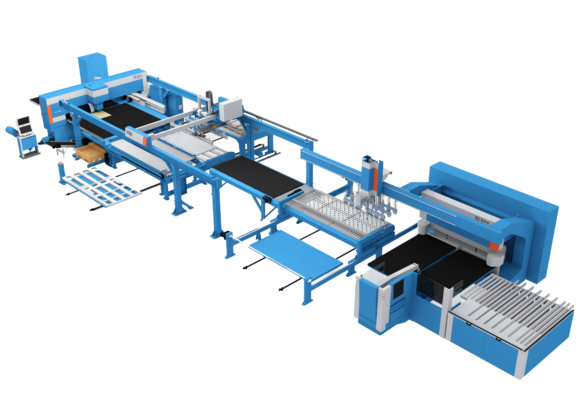

Punching, forming, tapping, marking, and laser cutting operations can be performed with a single machine using one of our combined punch-laser systems. This can increase flexibility and reduce the set-up time required to customize finished electrical cabinets immediately before coating. The flexible manufacturing method of the punch-laser combination also allows efficient production of low volume batches.

Our 2D laser machines can be used in the first stages of production, cutting the profile of the cabinet for further processing with other technologies, such as punching, bending and shearing.

The forming of electric cabinet panels is the best application for our panel benders. They are the best solution in terms of dimensions and thickness of the components, volume of work and batches.

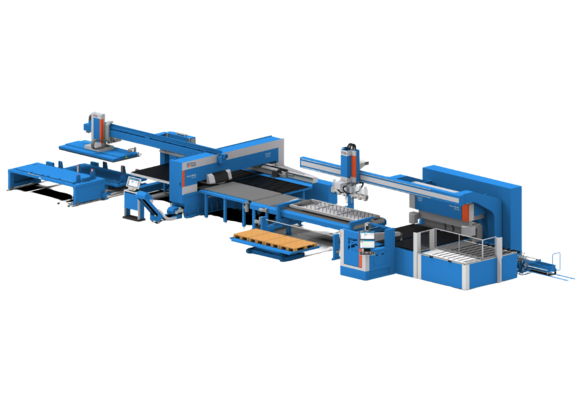

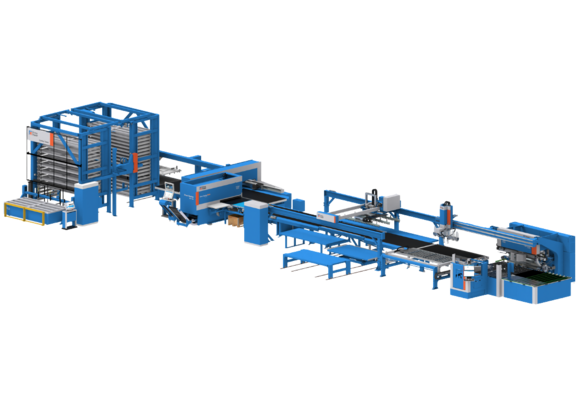

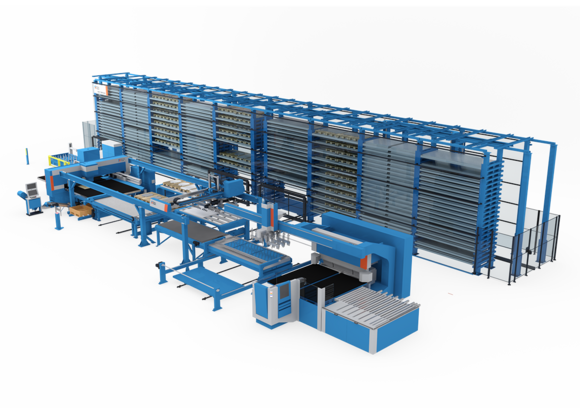

Fully automated production lines (called PSBB) are available for the high volume production of electric cabinets. The use of PSBB lines guarantees high productivity rates as well as excellent flexibility.

Our 3D laser cutting machines can be used to customize assembled cabinets before coating. Productivity can also be increased with shuttles or other automation solutions.

The wide range of Prima Power automation modules combines high productivity with flexibility and can be gradually integrated as production needs grow.

Our professional services complement our advanced technology and are the key to improved productivity and higher profit.

All our systems are designed and developed based on the "Green Means concept", which brings together productivity and eco-compatibility.

Application examples

Behind each component is a Prima Power machine

- all electric cabinet panels.

- customization of finished electric cabinets before coating

Related technologies

Browse our technologies to choose your machine

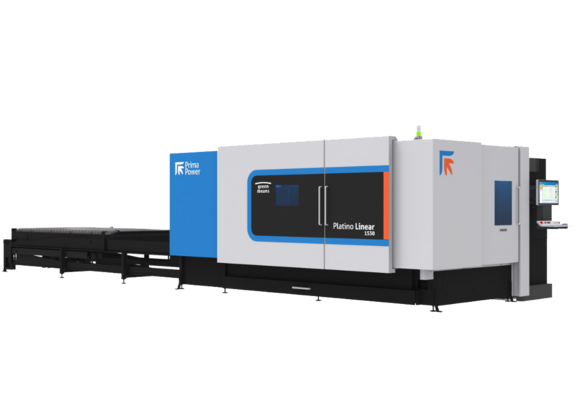

Platino Linear

2D LASER CUTTING MACHINE

The reliable and productive solution for cost-effective 2D laser processing

BCe Bending Centre

PANEL BENDERS

Flexibility at your service semi automatic panel bender combining flexibility and productivity

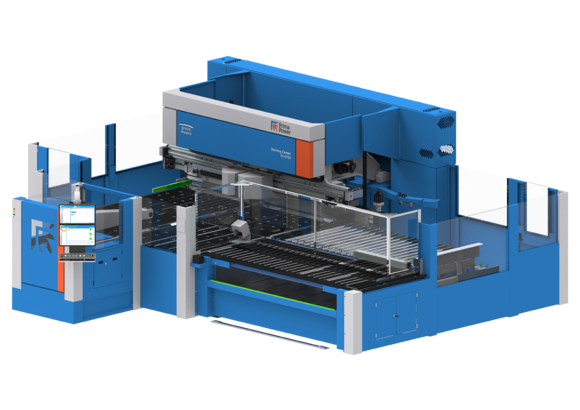

PunchBend

FLEXIBLE MANUFACTURING SYSTEMS

From cut-to-size material to ready-bent components

Night Train FMS®

FLEXIBLE MANUFACTURING SYSTEMS

Leading technology storage solution in automated flexible manufacturing systems

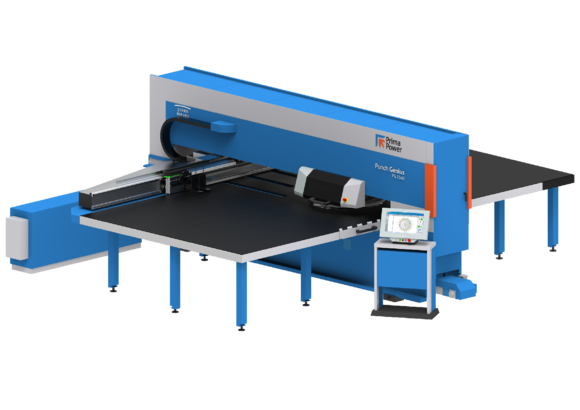

Punch Genius

PUNCHING MACHINES

Outstanding energy efficiency, low maintenance requirement and a high speed of operation.

FBe Fast Bend

PANEL BENDERS

The answer to multiple applications. Semi-automatic bending solution for simple, flexible and accessible production

STORIES OF EVOLUTION

Find out how a Prima Power machine took part in an Electric Cabinets company's success

Dringenberg - Boosting production capacity through automation and integration

The leading German manufacturer optimized its processes and achieved higher flexibility thanks to Prima Power's fully automated and integrated PSBB line.