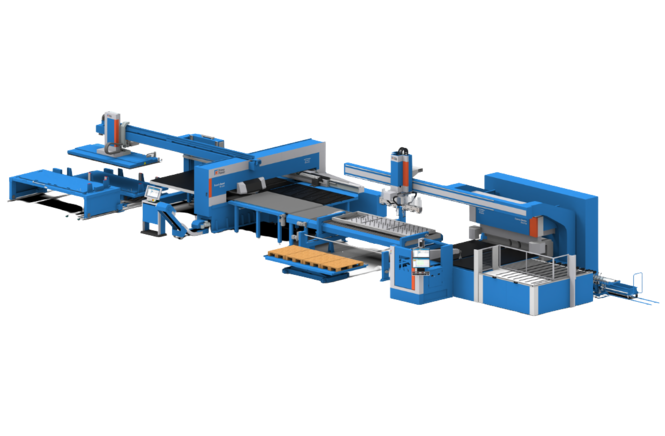

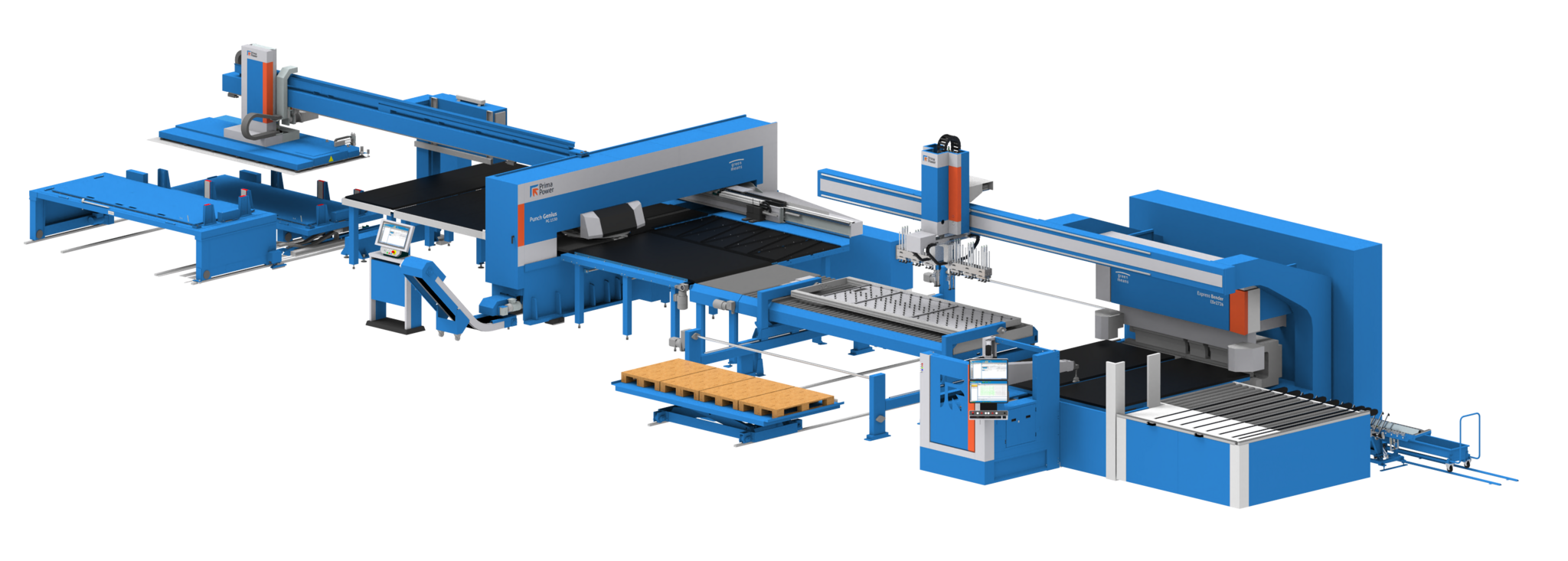

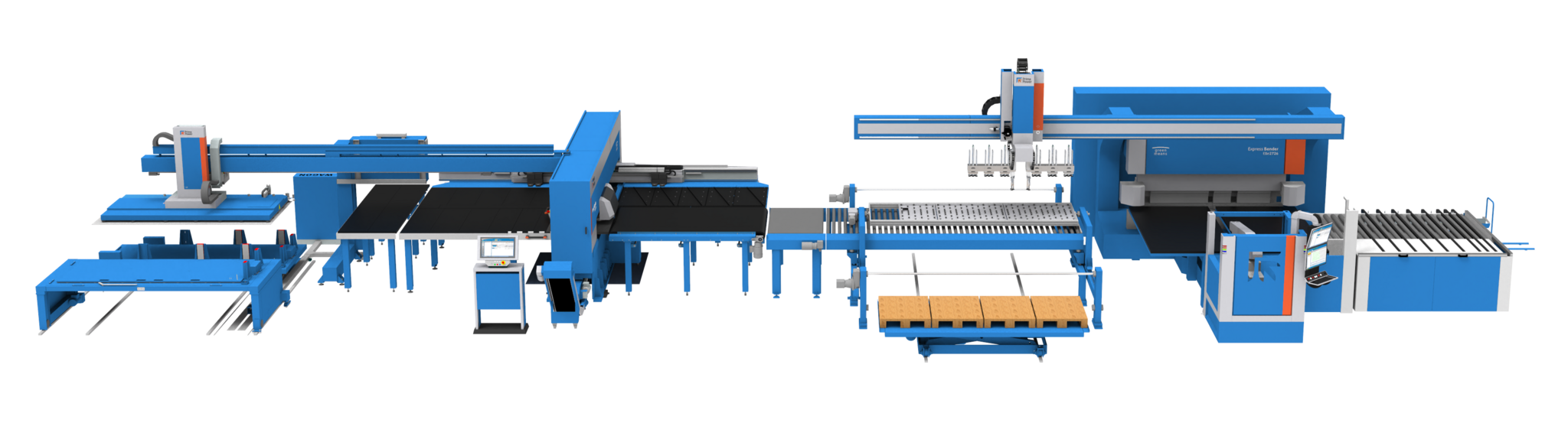

PunchBend

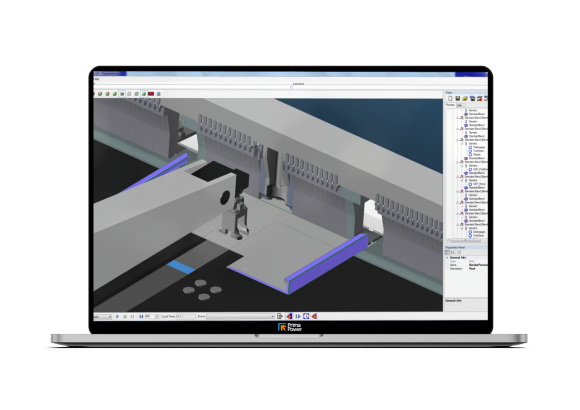

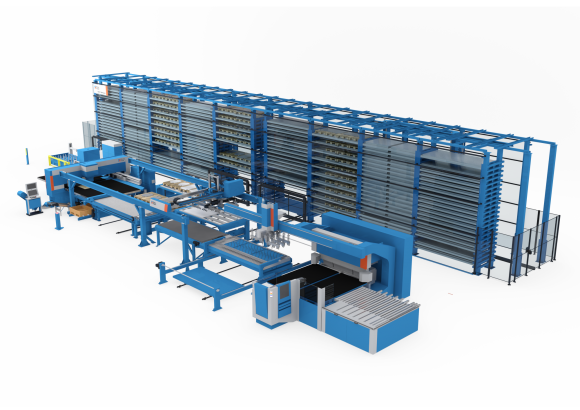

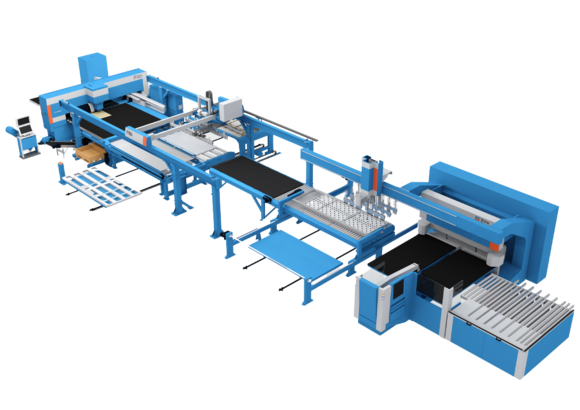

FLEXIBLE MANUFACTURING SYSTEMS

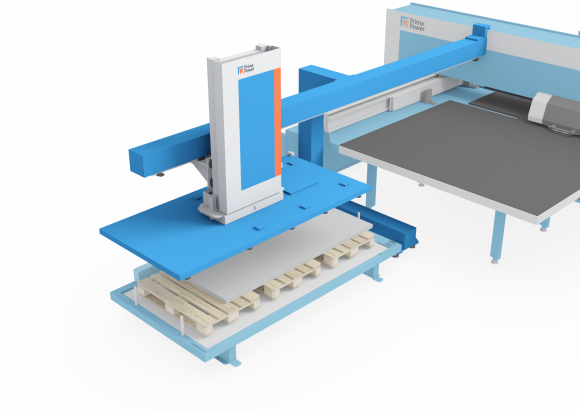

From cut-to-size material to ready-bent components

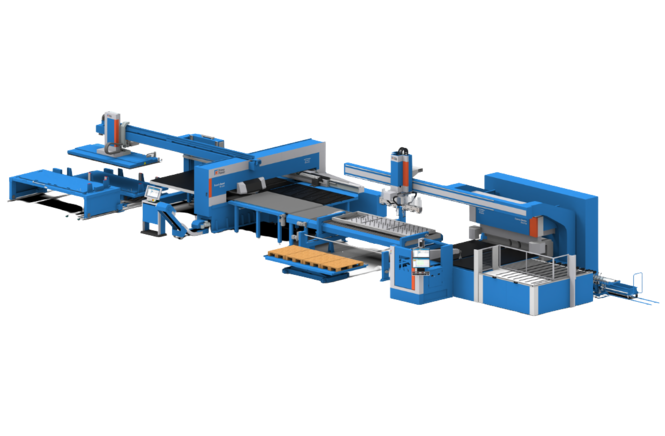

PRODUCTION ECONOMY

Advanced fabrication solution for cut-to-size materials.

ECONOMIC

Low maintenance costs and more production with less floor space.

LESS MAN HOURS - MORE MACHINE HOURS

Tightly integrated processes: software, work stages and material handling.

FASTER PRODUCTION

No skeleton-handling, efficient machine process. Shorter lead time for product changes and new products.

Prima Power PunchBend is a solution for the automatic fabrication of high-quality, ready-bent components from cut-to-size material.

Very often the fabrication process, when manufacturing steel furniture, lighting equipment, domestic appliances, heating equipment, boilers, steel doors, etc., enables the use of cut-to-size material for improved production economy. This is provided by the Prima Power PunchBend.

The most important characteristic of PunchBend is the tight integration of everything that is needed: software, work stages, and material handling. High productivity is achieved with fast loading and tool changes.

Sophisticated software, including graphic parametric programming and simulation at operator interface as well as offline programming

High component quality

High-performance values

Low energy consumption

Faster and smoother operation

Low maintenance costs

Compact footprint

= High productivity in most varied applications

Optimize your Prima Power machine

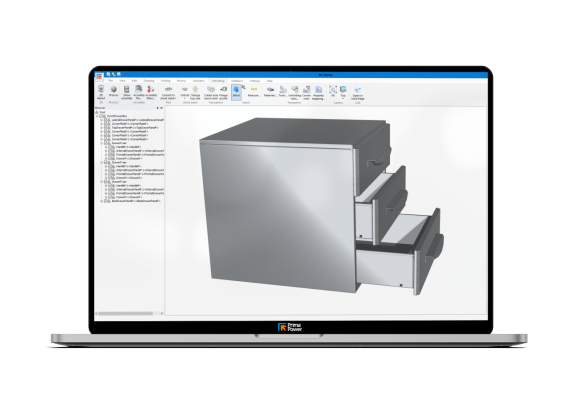

Master BendCam

MACHINE PROGRAMMING

Efficient managing of Prima Power bending machines through interactive graphical techniques

NC Express

MACHINE PROGRAMMING

Scalable CAD/CAM application that can be used for single part processing or as fully automatic batch processing software.

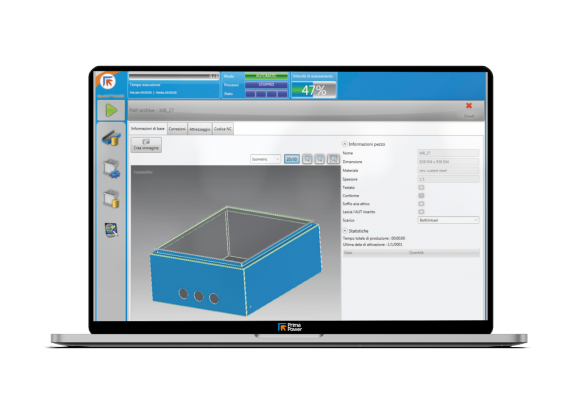

Tulus Storage

H.M.I.

Software for Combo Tower Laser and Night Train is a touch-operated user interface with visual and modern look and feel.

Tulus Cell

H.M.I.

Integrated and scalable software family for centralized management of fabrication.

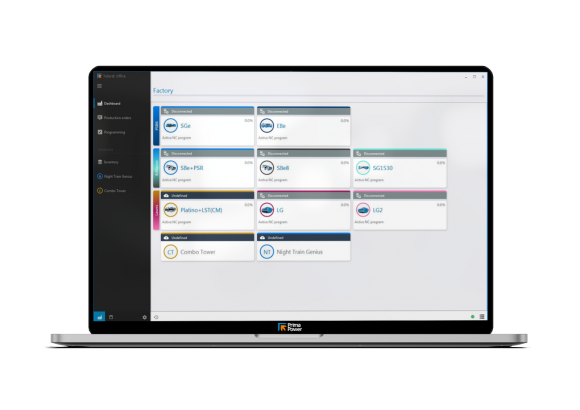

Tulus Office

PRODUCTION PLANNING

Work planning and controlling all machines in the factory.

Related technologies

RELATED AUTOMATIONS

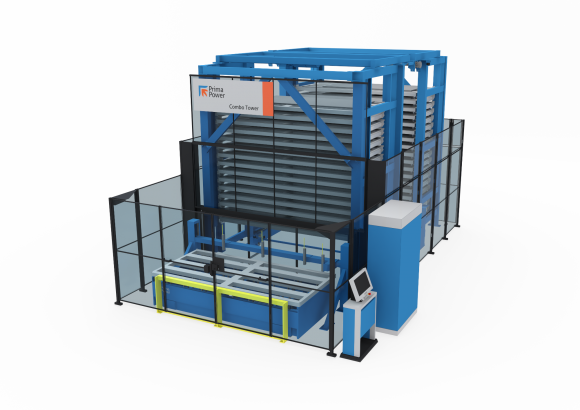

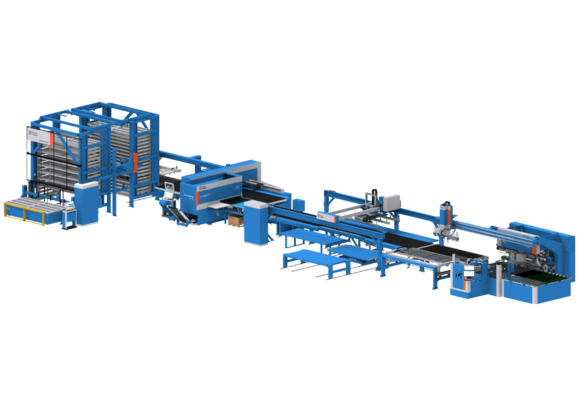

Night Train FMS®

FLEXIBLE MANUFACTURING SYSTEMS

Leading technology storage solution in automated flexible manufacturing systems

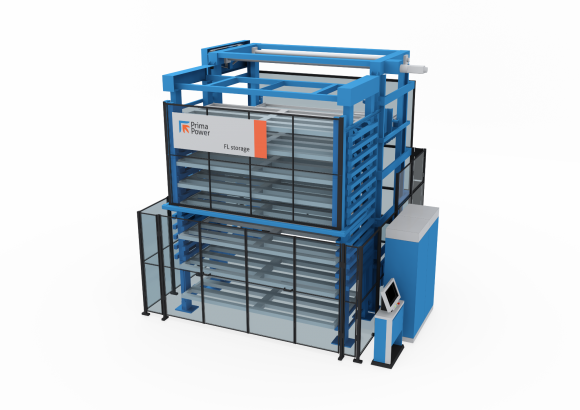

Fast Loading storage

STORAGE SOLUTIONS

A fast and economical solution for material flow

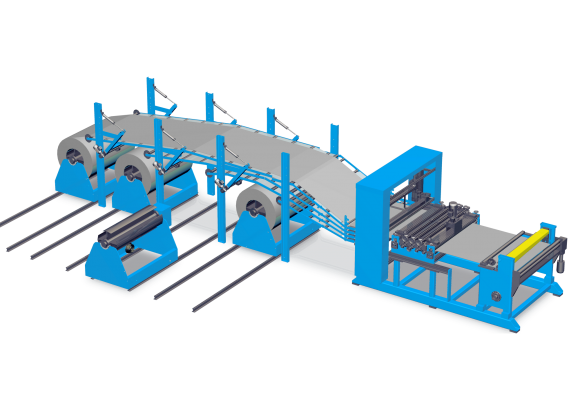

Cut-to-length

MATERIAL HANDLING

High productivity and flexibility with money savings

Take a look at the other products and choose the best solution

Night Train FMS®

FLEXIBLE MANUFACTURING SYSTEMS