Master BendCam

MACHINE PROGRAMMING

Efficient managing of Prima Power bending machines through interactive graphical techniques

Flexibility:

Master BendCam is a production management tool designed to get the maximum positive impact in terms of flexibility and efficiency

Easiness of use:

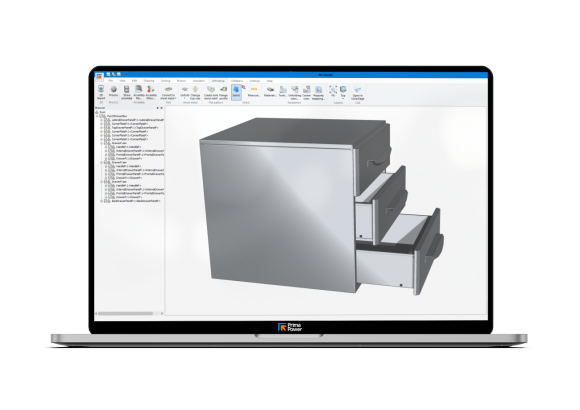

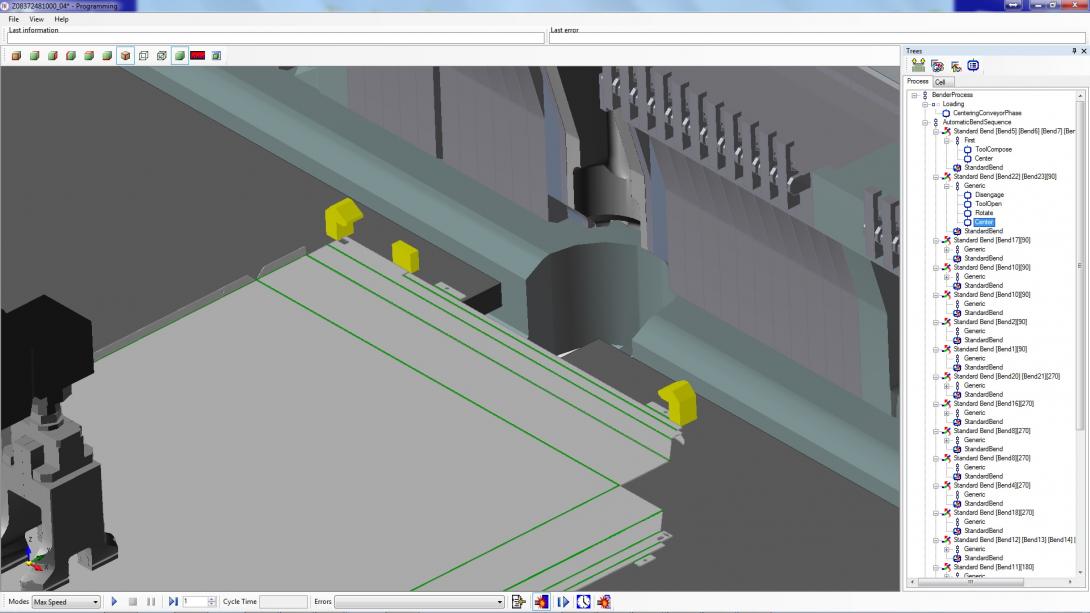

simplified programming through interactive 3D graphics

Safety:

intuitive and secure tool configuration and collision control system.

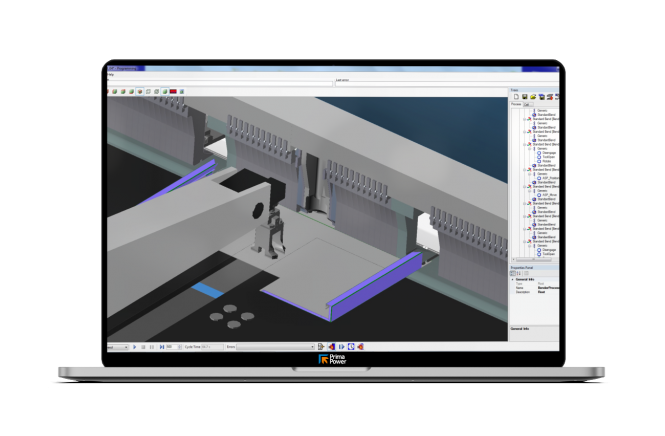

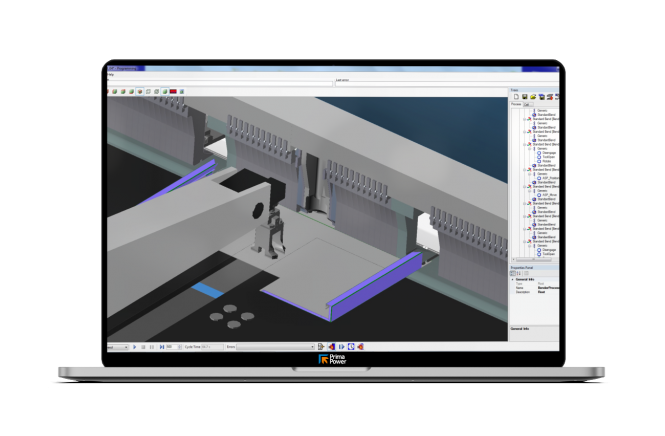

Master BendCam programming system is a user-friendly, integrated tool for managing Prima Power Panel Benders through interactive graphical techniques in an efficient way. It is designed to meed maximum positive impact on manufacturing flexibility and efficiency.

The system may be used as a single part drafting and tooling program, or as a fully-automated machine tool management system. It simulates the working process in a real manner and generates programs with a greater degree of automation.

Master BendCam is supplied as part of standard machine delivery in a Basic version, which allows the display of the bending sequence in 2D.

Different packages are available for customers as follows:

- Master BendCam 3D on board and offline

- Floating Master BendCam license for 3 users

- Floating Master BendCam license for 5 users.

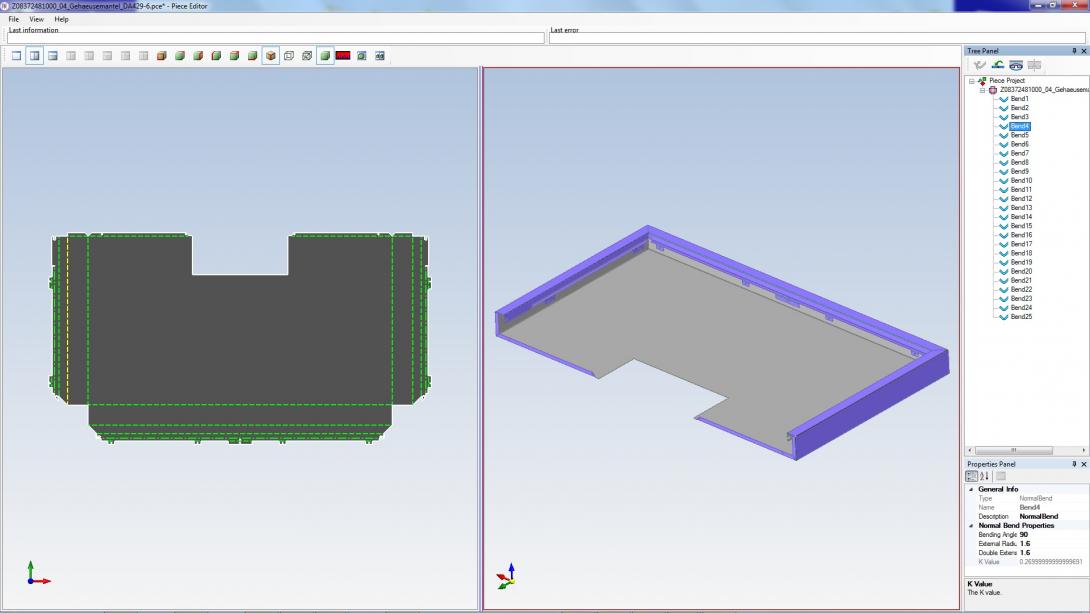

The operator can program a part by importing a 3D model in the most known and used formats (e.g. IGES, STEP, SAT, STL etc.) or a dxf with possibility to correct possible problems in advance.

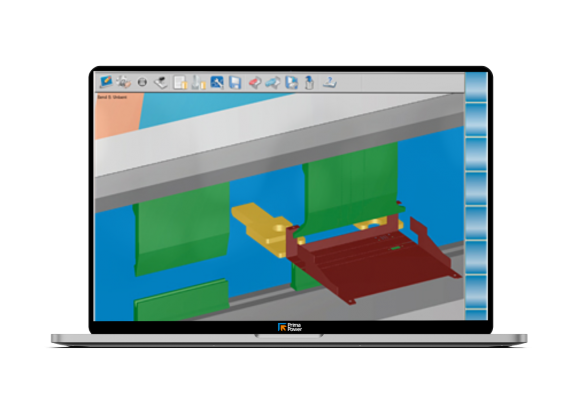

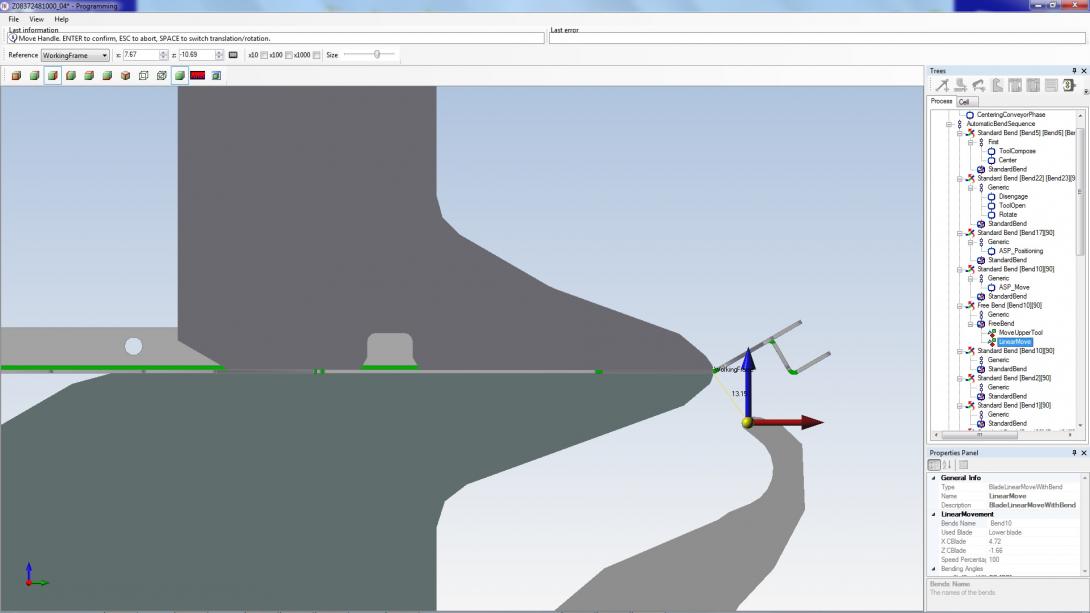

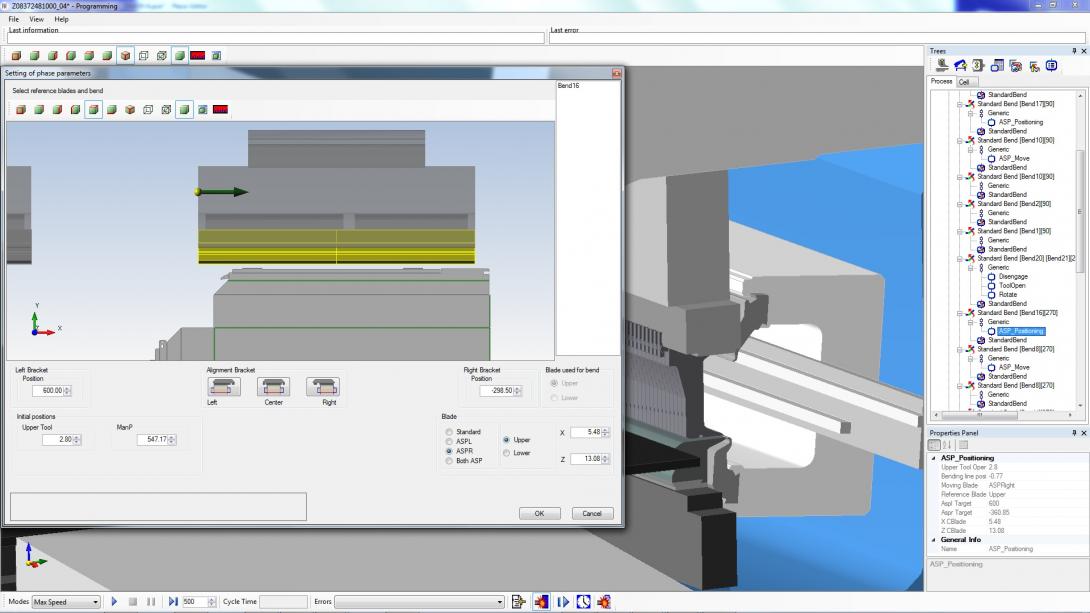

Simplified programming through pre-set bending cycles

Possibility to introduce very complex elaborated bending sequences by editing a limited number of parameters.

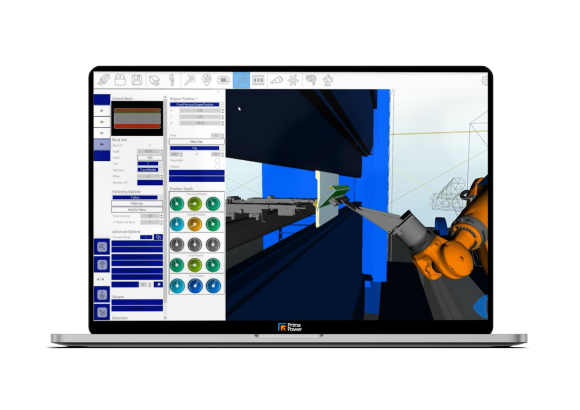

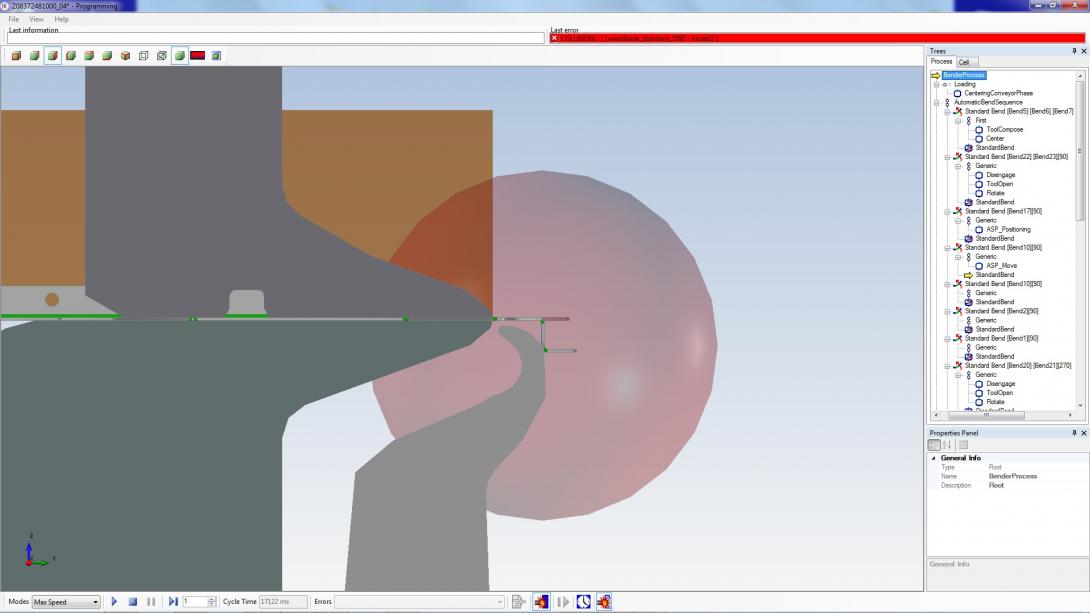

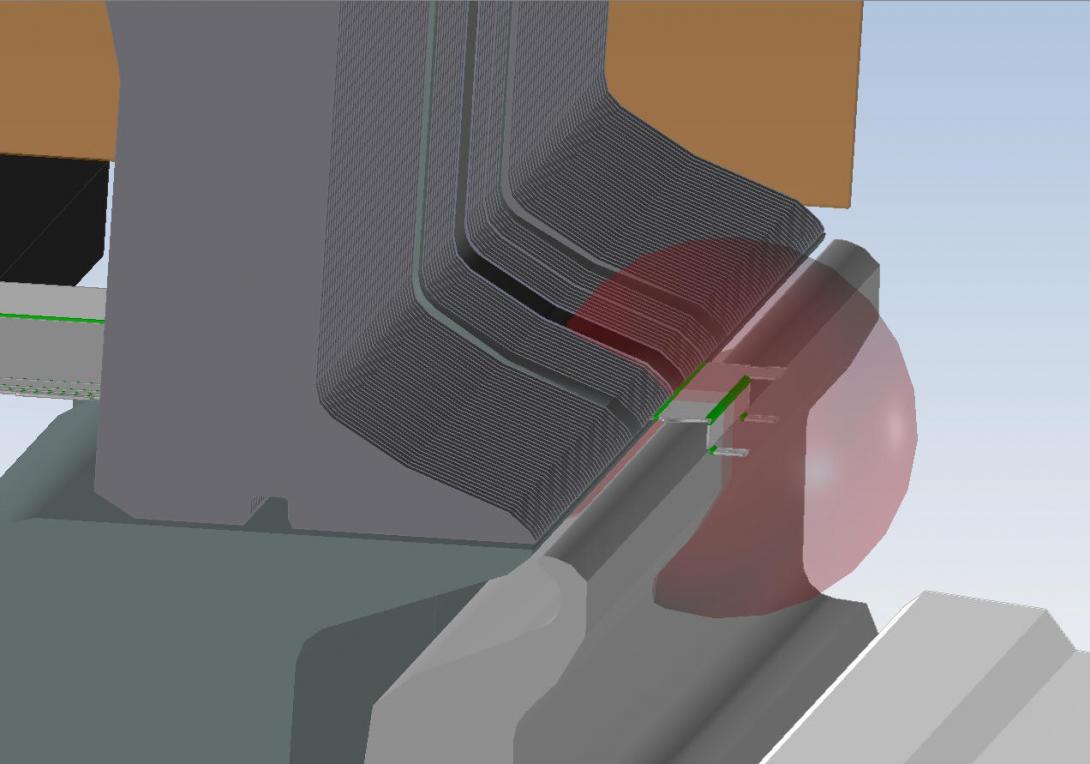

Collision checks between parts and tools

The software detects automatically possible collisions between parts and tools by warning the operator through a clear alarm.

The collision check can be easily activated or deactivated by clicking on a dedicated icon.

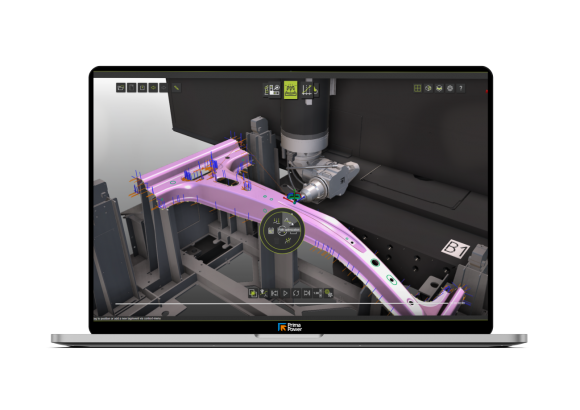

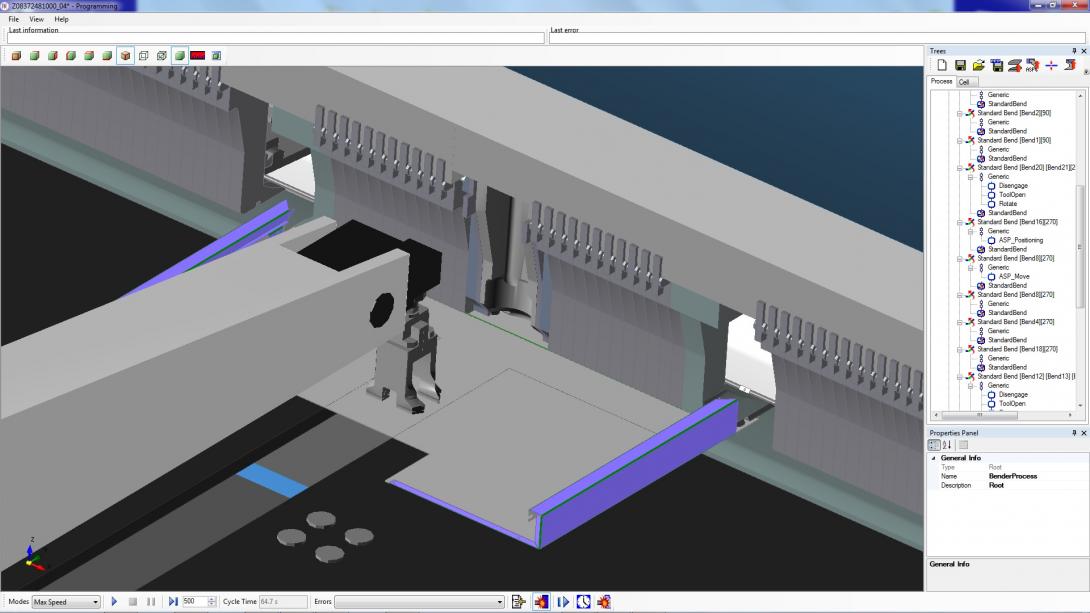

Realistic 3D simulation

The complete 3D simulation of the bending process allows a better optimization of the operations and a quick correction of possible mistakes during the off-line programming, thus avoiding waste of time during the working.

Parametric function

Master BendCam Parametric allows stretching X and Y dimensions with automatic internal holes and bumps management and automatic tooling.

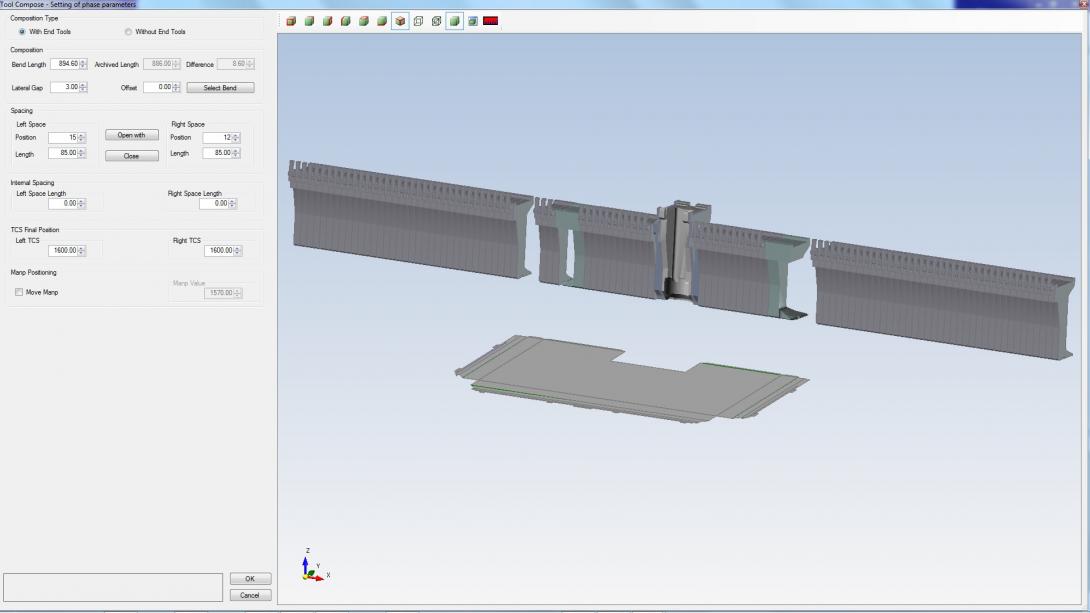

Tools setup

The operator can add and remove machine tools through the graphical interface to define and change the machine configuration

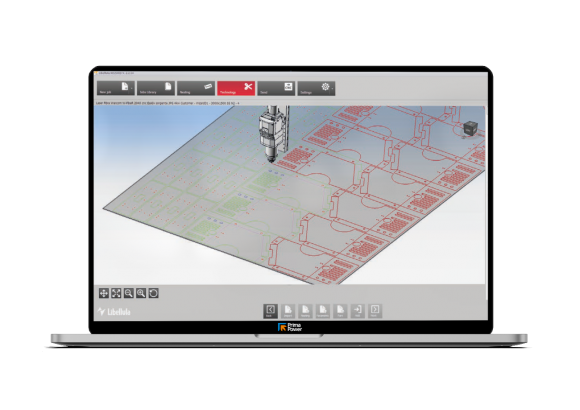

Cycle times calculation

Thanks to an accurate calculation of the running time, it is possible to know the time required to process each part.

Take a look at the other products and choose the best solution

NC Express

MACHINE PROGRAMMING

Scalable CAD/CAM application that can be used for single part processing or as fully automatic batch processing software.

AutoPol BendSim

MACHINE PROGRAMMING

Easy-to-use and effective tool for off-line programming of all Prima Power P series brakes.

Wizard

MACHINE PROGRAMMING

Revolutionary CAM application, Nesting, technology, and machine code in 4 steps to combine ease of use and quick machine preparation.

Prima Power 3D CAM

MACHINE PROGRAMMING