Facing Adversity and Winning with Prima Power Equipment

How many job shops could lose a customer that accounted for 98% of their business and recover in just a few years? Elm Machining was faced with that scenario several years ago.

The company confronted this threatening challenge by making some hard decisions, placing additional emphasis on fabrication, investing in the proper equipment, and dedicating itself to the hard work that it took to not only survive, but prosper.

Elm Machining was founded 40 years ago in Elmhurst, IL near Chicago. At the time, Elm was mainly a tool & die and metal stamping operation. The company expanded and grew over the years, and in 2005 Elm Machining moved its facility to Eufaula, AL, when its largest client also moved down to the area. “In 2012, the large client announced that it was moving its operation to Mexico, and they would no longer require our services,” reflects Scott Aimone, president. “This client represented roughly 98% of our business, and the announcement came as quite a shock since we had just been awarded the company’s vendor of the year award. At this time, we had just purchased a laser and a press brake to complement our straight side and GAP punch presses. We were new to the fabrication part of the business. We were also at a low point in the company. During this pivotal period, we needed to make decisions and investments to push the company forward and regain the business we had lost.”

Aimone notes that that most of the time when he was quoting jobs, he was competing with another job shop that had a turret punch press, a larger press brake, a faster laser, with higher capabilities when it comes down to timing. “We decided that we needed a turret punch press to obtain the competitive edge in the market.”

Servo-electric Turret Punch Press

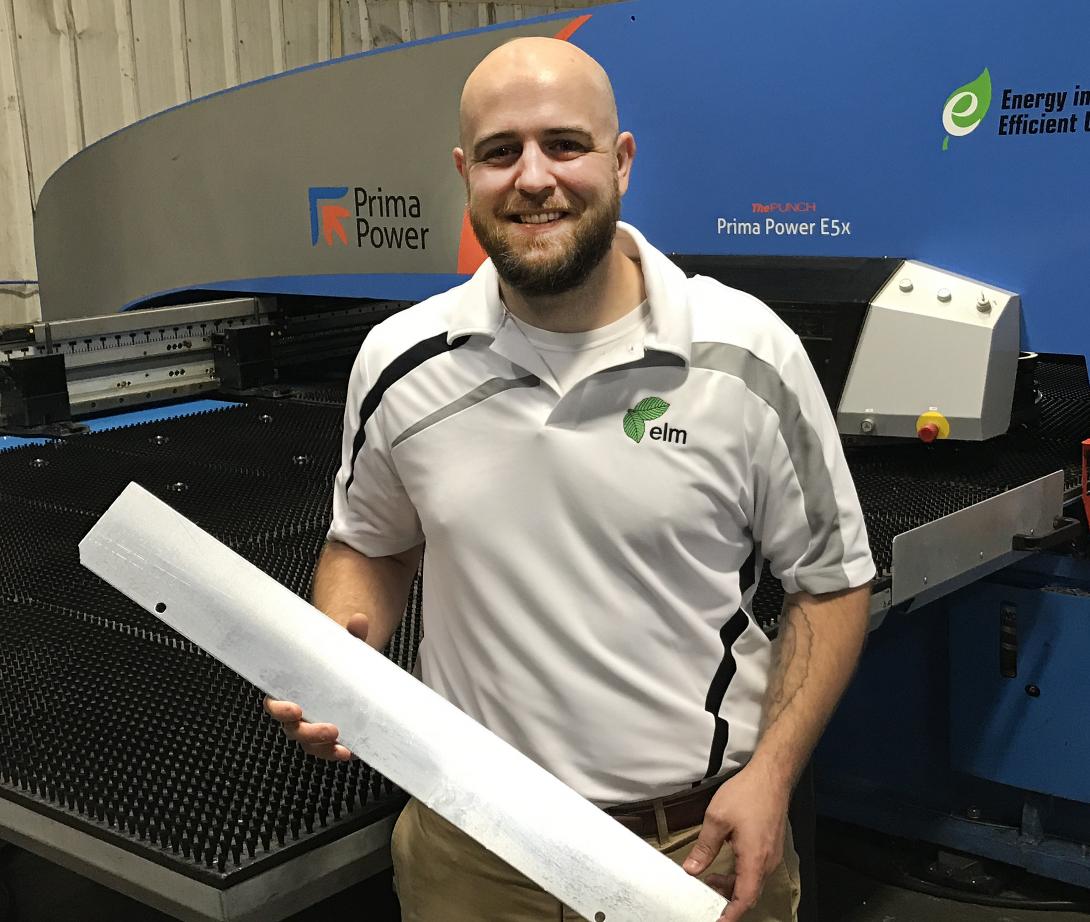

Elm Machining compared features and benefits of several turret punch press builders. In 2014, the company purchased the E5x from Prima Power. With the E5x by Prima Power, servo-electric punching productivity is available in a flexible and affordable package. It has been designed to be user friendly with versatile capacity. Prima Power’s machine control and user interface software with a touch screen panel ensure fast setup and convenient operation. The machine has the ability to process full 1,250 mm x 2,500 mm sheets without repositioning and makes nesting of the part more efficient and economical.

Other features of the servo-electric turret punch include:

- Extremely high servo-electric accuracy for less scrap, more production, and excellent forming and marking capability

- Fully-programmable punching speed, upper and lower limit of stroke

- Programmable Clamp Setting

- Robust O-frame design for perfect tool alignment and less wear on the punching tools

- Touch screen and Tulus Lite user interface

- Average power consumption of 4 kW for less energy use

“In addition to the Prima Power, we also looked at competitors’ machines,” explains Aimone, “but there weren’t as many customization features in their models that would fit our needs as a job shop. The biggest selling point of the Prima Power turret punch for us was the multiple Auto-Index stations that tremendously reduced the cost of tooling for us. We purchased the turret to acquire new business and possibly take some work from our other machines and transfer it to the turret. When the machine was installed, our clients began asking for quotes. This was a huge pivotal point for our company when all that business was transferred to us. Prima Power turret punch press has definitely doubled our business. It has also made us more competitive in the market when it comes to pricing and lead times.”

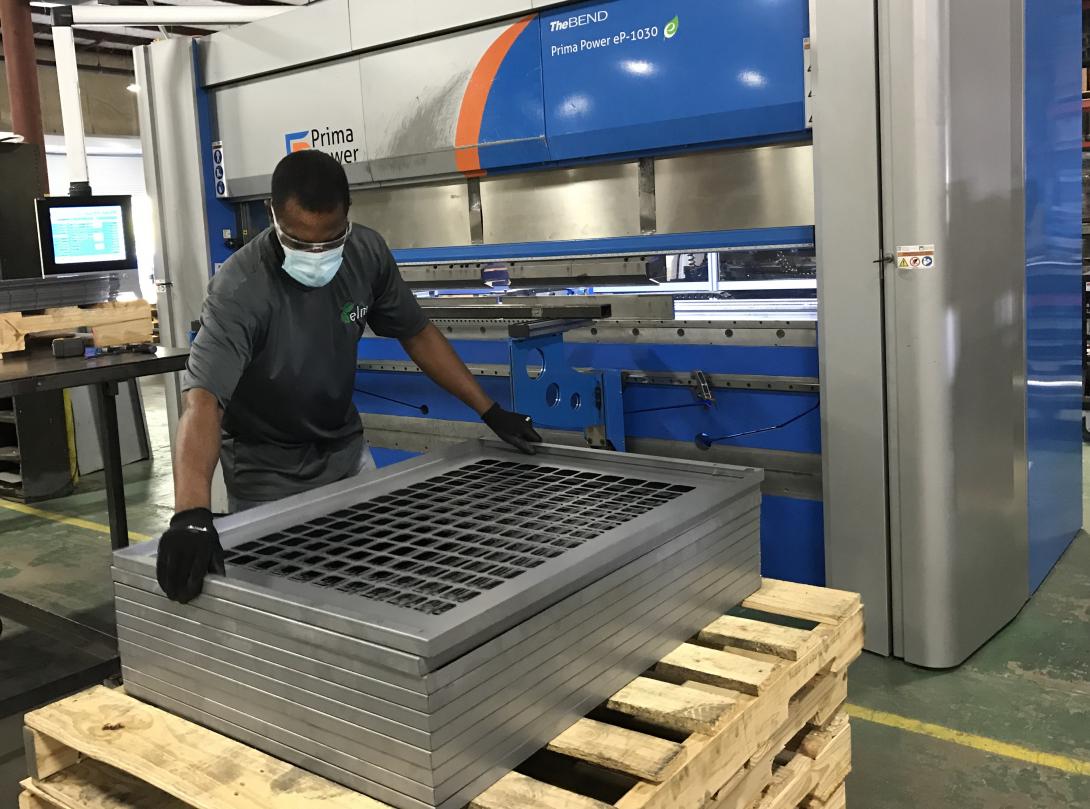

eP-1030 Press Brake

Elm Machinery purchased the Prima Power eP-1030 servo-electric press brake in 2017. Prima Power has applied a servo-electric drive system on the eP-Series press brake. It is a fast, accurate, non-hydraulic bending solution. The innovative machine concept combines productivity, accuracy, flexibility, and reliability with high respect to ecological aspects that the company calls “Green Means®”. The concept offers both sustainability and manufacturing efficiency and productivity. It also means greater versatility, lower power consumption, less maintenance, and no oil to purchase or to get rid of. In addition, easy programming and outstanding accuracy eliminate waste production. The net result is the ability to form higher-quality sheet metal parts at a lower cost.

An operator-friendly 17” touch screen user interface leads to a significant improvement of data input rates and a considerable reduction in programming time. 2D graphical programming with automatic bending sequencing will assist in making even first-time operators productive.

AutoPOL off-line programming

AutoPOL is an easy-to-use and effective tool for off-line programming of Prima-Power eP-Brakes. Sophisticated bending simulation makes it possible to shorten set-up times and ensure that the bending task can be performed. 3D models can be created with AutoPOL's designer program or they can be imported in 2D and 3D-format from practically any CAD program.

“In addition to the eP-1030, we also have an older hydraulic press brake,” says Aimone. “The reason that we purchased the eP-1030 was the result of all the extra business that came in because of the turret punch press. The feature that I like best about the eP-1030 is the servo-electric operation. I also like the AutoPOL program. It is one of the best programs of forming software that I ever used. In addition, the user interface is a huge plus. It’s very simple to use for my operators to read and adjust. The eP-1030 has expanded our capabilities to form larger parts and has increased our precision and quality.”

A Winning Combination

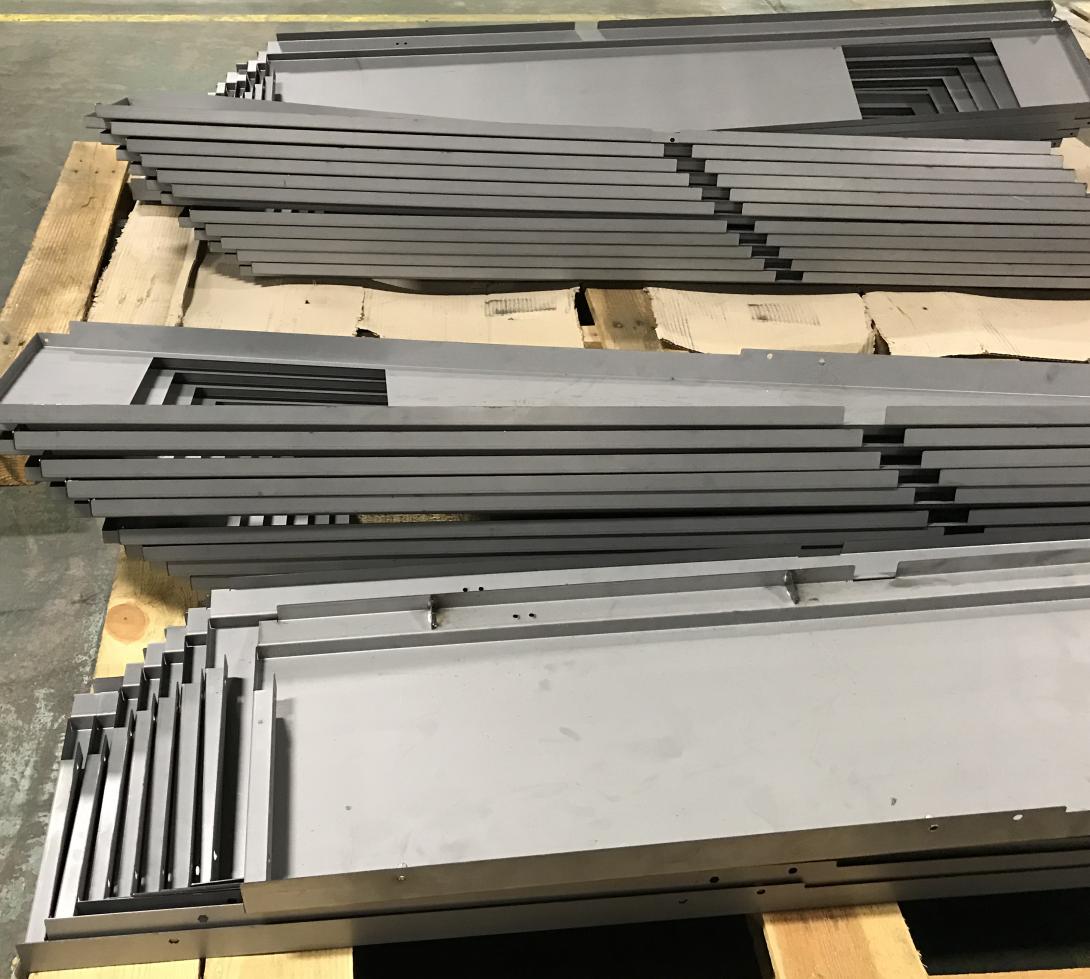

“Prima Power servo-electric punch press was the impetus for our increased production business,” continues Aimone. “Before the E5x, our business was about 98% lighting. It allowed us to enter a number of new industries such as construction, industrial air compressors, electronics, heat transfer and others. The E5x also made us more competitive in this market. We grew substantially with Prima Power punch press. We were in a 20,000-square-foot facility from 2005-2017. In 2017, we moved to our current location, a 40,000-square-foot facility. That’s how quickly we had to move to a larger facility… and how quickly we regained the business we had lost. To keep up with demand, we added a second shift in 2018.”

No COVID-19 Slowdown

“We have been very fortunate that our business has not been affected by COVID-19,” explains Aimone. “In fact, business has gone up. We have a very good mix of clients in both industrial and residential. It was a very odd thing to see this year, because we typically have a busy season with both. We received letters from our clients that we were an essential part of their business and they were considered essential businesses. Eufaula, AL is a small town and COVID-19 really didn’t affect us as hard as it has other cities and states.”

A Great Partnership

“When we purchased the Prima Power equipment it increased our sales by 50%,” says Aimone. “The following year sales increased another 50%. Today, we are almost at full capacity running double shifts on both the E5x and the eP press brake. In 2018 - 2019 our growth was 20%. And from 2019 – 2020 we are at a 13% growth. We are receiving more requests from clients than we can fill. That is why we are considering the new laser and press brake in the near future.

“The Prima Power machines have helped our business,” concludes Aimone. “These were big purchases for our company at that time when we were at our worst, and this a major turning point that helped us gather the competitive edge. We would not have been able to increase the business as much as we have without the Prima Power machines. The Prima Power turret paid for itself within a two-year period. The eP-1030 payback was less than a year.”

We would not have been able to increase the business as much as we have without the Prima Power machines. The Prima Power turret paid for itself within a two-year period. The eP-1030 payback was less than a year