Laser Next 2141

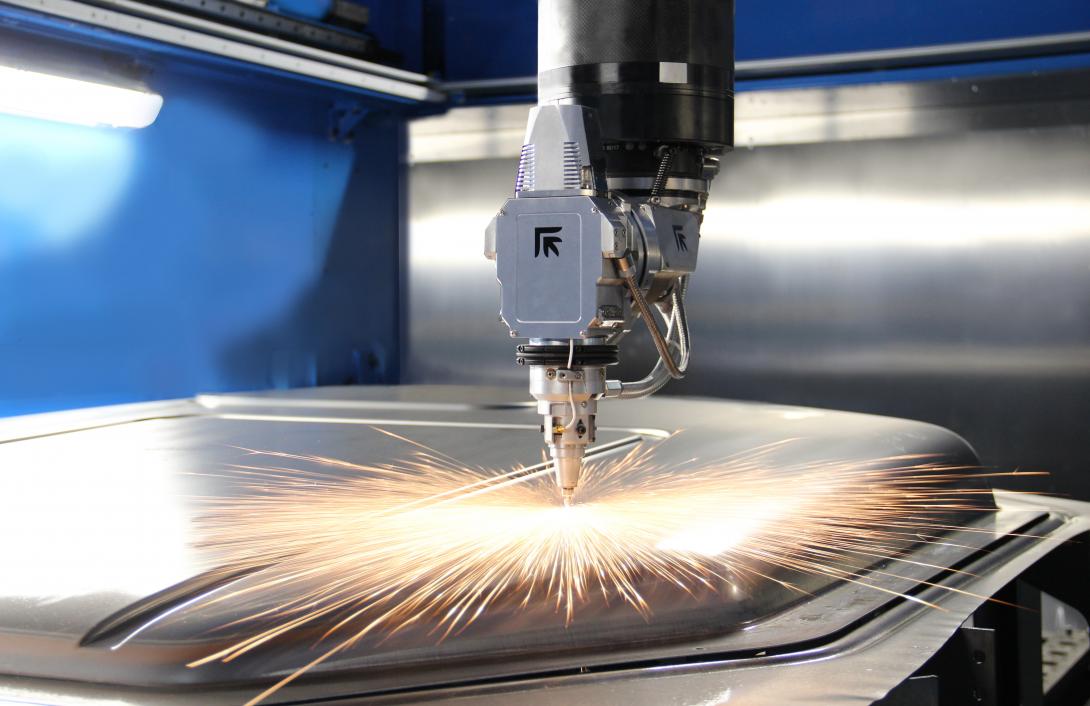

3D LASER CUTTING MACHINES

The flexible solution with large working envelope and best-in-class efficiency

FLEXIBLE

Different applications with a single machine. 3D cutting, 2D cutting and welding in a single multipurpose solution with multiple machine configurations.

RELIABLE

Fully tested and reliable thanks to the experience of the successful Laser Next platform.

HIGH CAPACITY

Very large working envelope for large parts processing combined with reduced footprint.

EFFICIENT

Higher Overall Equipment Efficiency due to reduced downtime and maintenance. Less resources dedicated and no special skills needed for simplified maintenance.

Laser Next 2141 is designed and developed to satisfy the needs of stamped-metal-parts manufacturers in diversified industrial sectors, such as job shops, press shops, aerospace, agricultural, automotive, and provides them an unparalleled flexibility in terms of processes, part sizes, and configurations, combined with state-of the-art performance, quality, and accuracy.

The Laser Next 214 combines the efficiency and productivity of the other Laser Next products with a unique flexibility.

Thanks to multiple machine configurations (fixed tables, split cabin, shuttles and turn table) it can meet any production need:

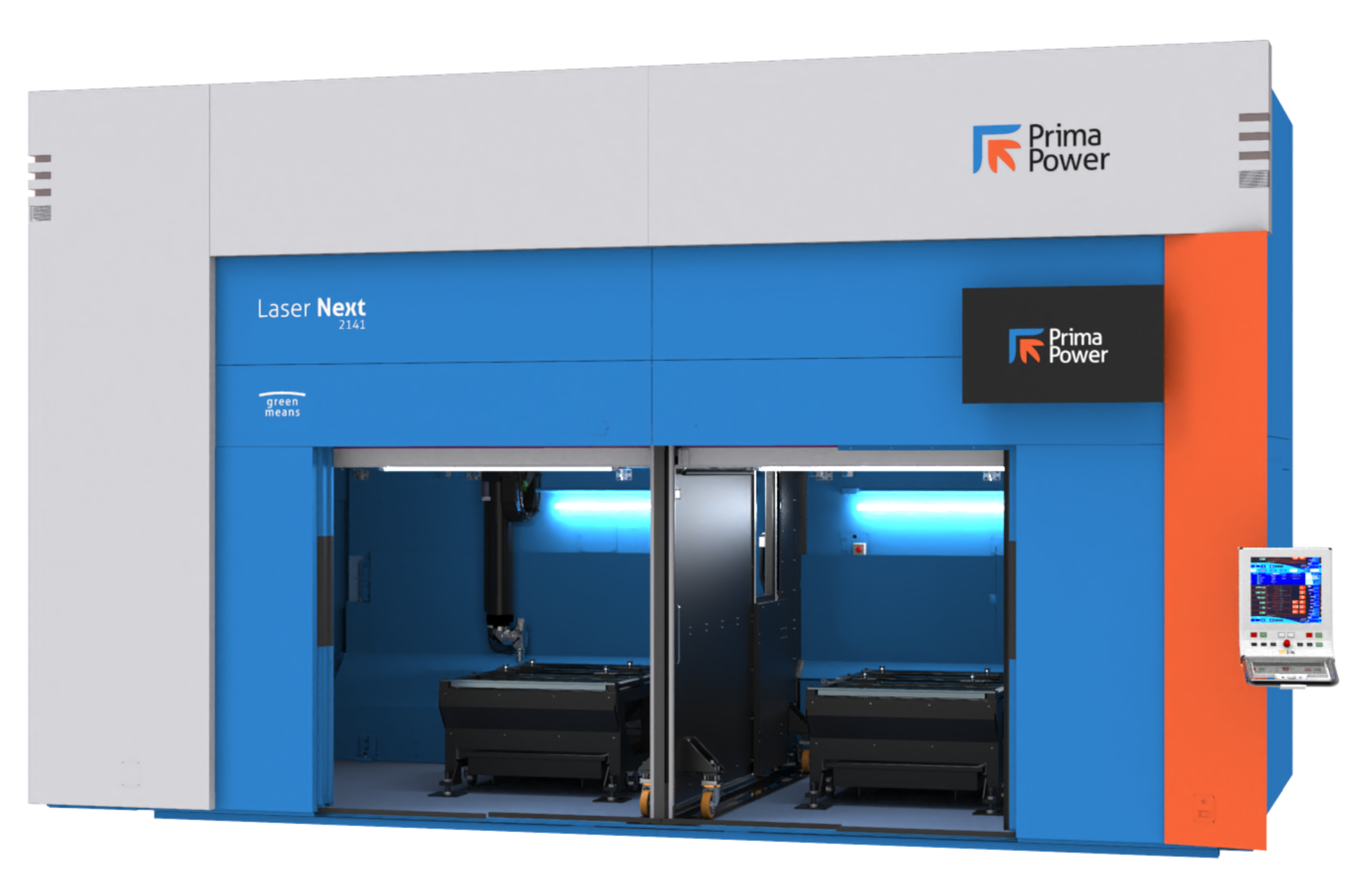

Fixed Tables configuration: the standard version with Fixed Tables exploits the entire working envelope to process large parts and features great accessibility from all sides.

Split Cabin configuration: with the Split Cabin configuration, the working volume is separated by a removable wall and a sliding roof into two halves, where the parts are alternatively processed or loaded/unloaded in total safety. In this way, machine productivity is increased and, when needed for larger parts, the wall can be removed to restore the entire working envelope.

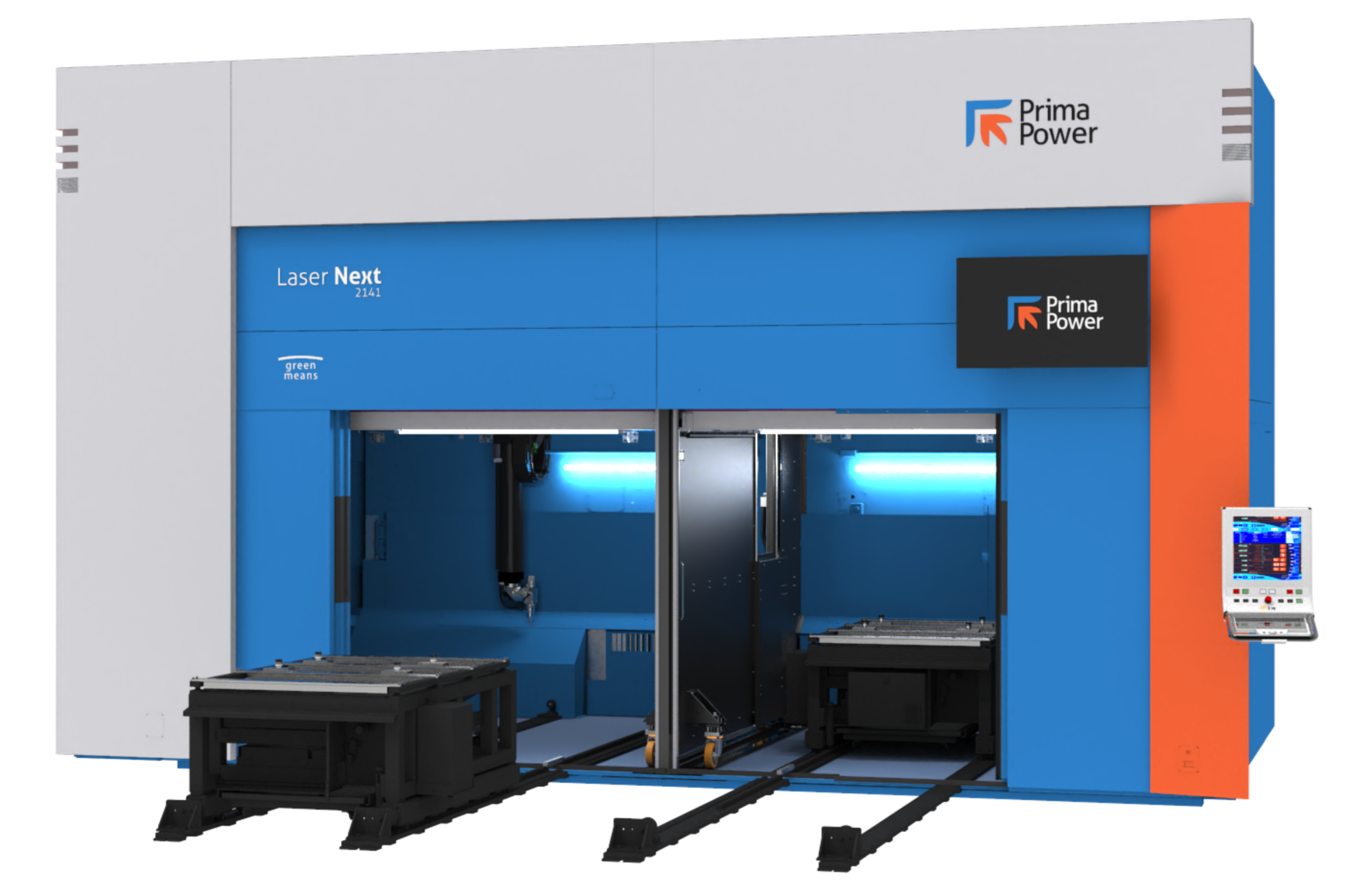

Shuttle Tables configuration: the Shuttle Tables version allows the fast and automatic movement of parts and fixtures outside the working area from the sides or the front of the machine. This is the solution for allowing large and heavy parts to be handled outside the working area and in case of complex set-up. Combined with the Split Cabin, the Shuttle Tables configuration also allows cover time operations

Turn Table configuration: for the fastest part handling operations without machine stops (cover time operation), the Turn-Table configuration is available. This is the ideal solution for large-series production of medium to large-size parts.

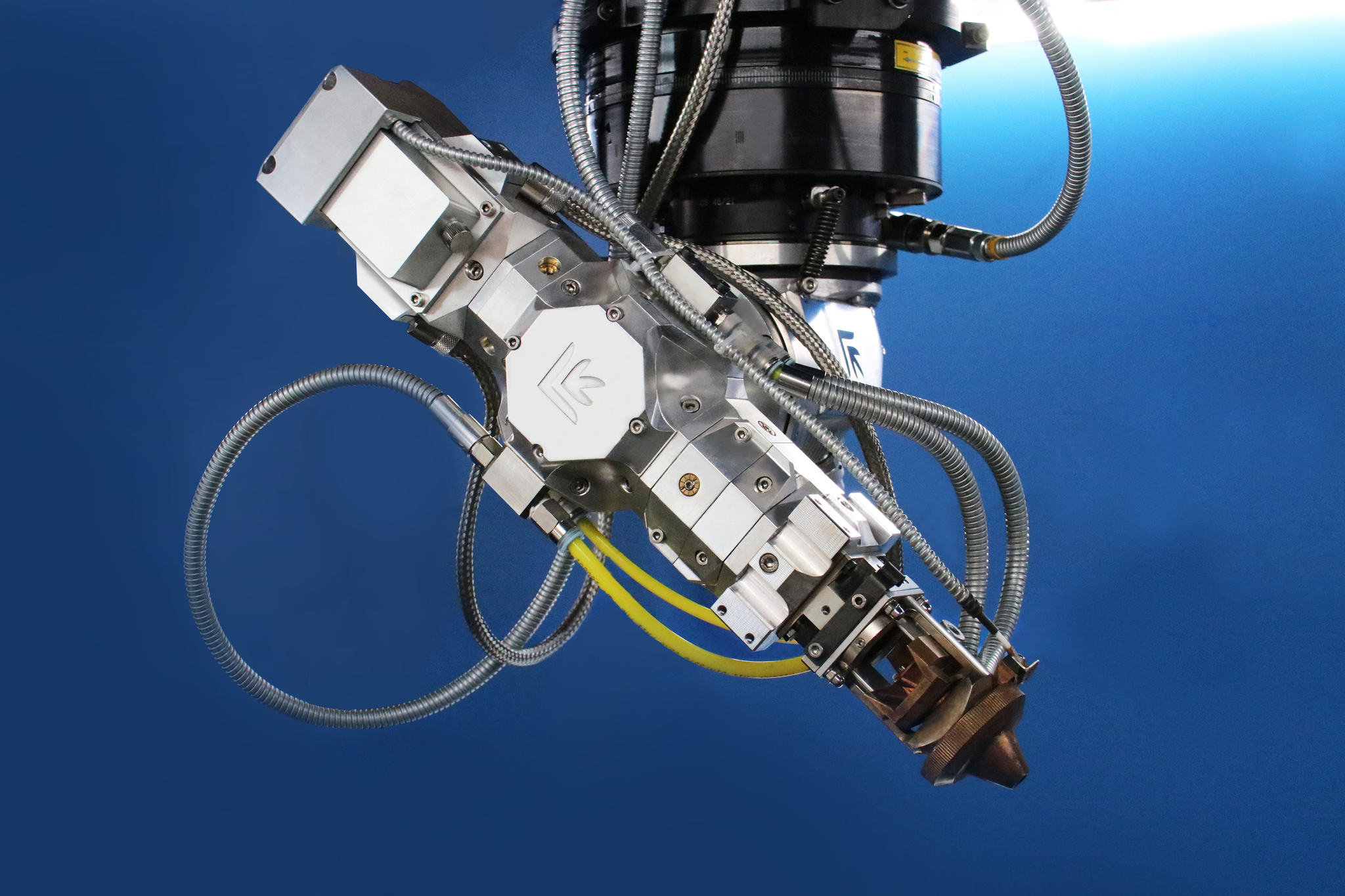

Laser Next 2141 is equipped with linear motors on main axes and direct motors with optical scales on the focusing head for superior dynamics and precision.

The synthetic granite frame with state-of the-art topology optimization methods of Laser Next 2141 grants smooth and regular machine movements, even at the highest dynamics, allowing high quality cutting results.

Thanks to the advanced dynamics control it is possible to get the best performance, even on large parts processing.

The high energy efficiency fiber laser, with low maintenance required and no laser gases, contributes to reduce the operating cost of the machine.

The user-friendly and powerful CAM software allows an easy and quick generation and testing of the entire cutting program.

Work area

X 4,140 mm, Y 2,100 mm, Z 1,020 mm

A 360° – B ±135° – C ±12 mm

Axis speed

X, Y, Z 120 m/min

A, B 1.5 rps

Accuracy*

Pa, Ps 0.03 mm (VDI 3441)

Laser source Fiber 3,000 W – 4,000 W

*The accuracy of the piece depends on its type, size and pre-treatment, and the conditions of application.

Optimize your Prima Power machine

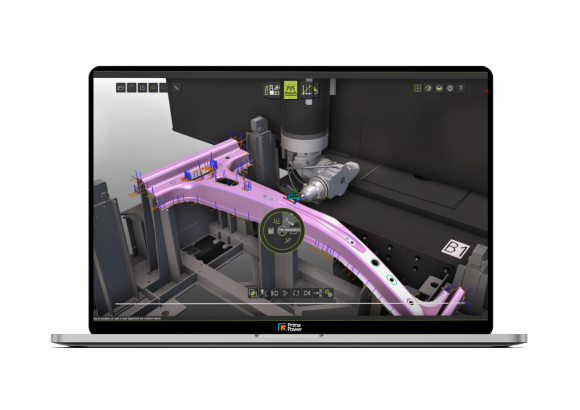

Prima Power 3D CAM

MACHINE PROGRAMMING

Cam application to program 3DLaser machine, provided by partner CENIT, in 3 license levels to support different use-cases

Tulus Analytics

PRODUCTION REPORTING AND MONITORING

Parts production and machine performance reporting

Related technologies

Related industries

Take a look at the other products and choose the best solution

Laser Next 1530-2130

3D LASER CUTTING MACHINES

The 3D laser system for automotive production

Laser Next Core 2131

3D LASER CUTTING MACHINES

Versatility meets cost-efficiency in 3D laser processing

Giga Laser Next

3D LASER CUTTING MACHINES