Rapido

3D LASER CUTTING MACHINES

Productivity, quality and efficiency with unmatched price

FLEXIBLE

Different applications with a single machine. The working area can be divided in two halves thanks to a movable partition wall and a sliding roof.

RELIABLE

Fully tested and reliable thanks to the long-lasting experience in the widest range of applications.

USER FRIENDLY

Easy to use programming software and Prima Power operator interface. Fast setup and reduced downtime.

PRODUCTIVE

High productivity, quality and efficiency: best in class for machine architecture and control solutions.

Today the real challenge for laser machines manufacturers is to combine productivity with efficiency and eco-friendliness. RAPIDO is the key to these modern needs.

RAPIDO features high class performances in every application field. Thanks to specialized solutions, it is very flexible, and conversion from one type of production to another is quick and easy.

A fast changing system of the head attachment allows cutting of higher thickness materials, welding with gas protection through a coaxial nozzle or a dedicated trailing shield.

A typical cutting application are automotive parts in mild steel or aluminum.

With the SPLIT CABIN option, the working volume is separated by a removable wall and a sliding roof into two halves, where the parts are alternatively processed or loaded/unloaded in total safety. In this way, machine productivity is increased and, when needed for larger parts, the wall can be removed to restore the entire working envelope.

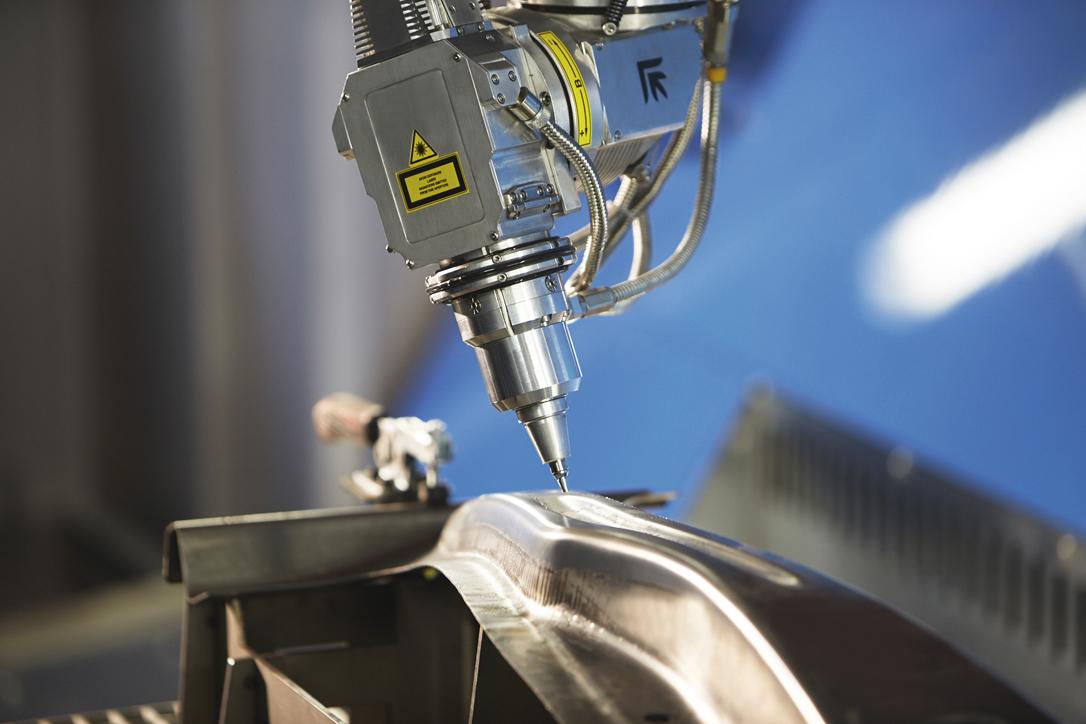

The Rapido focusing head with direct motors and optical scales grants high dynamics, accuracy, no backlash, reduced maintenance and robustness. Welding head it’s also available as option.

Rapido is equipped with high brilliance fiber laser with high energy efficiency, no maintenance and eco-compatible use.

User-friendliness is further enhanced by the machine great accessibility thanks to the overhead retractable arm, cantilever structure and no sagging.

The synthetic granite frame of Rapido is designed with state-of-the-art topology optimization methods resulting in the smooth movements, even at the highest dynamics.

The focusing head of Rapido, in common with the other Prima 3D machines, is sealed and compact and equipped with two anti-crash system to prevent any damage. The cutting nozzle can be used as a measuring tool to speed up the set-up time as well as to validate parts directly on the machine.

The user-friendly and powerful CAM software allows an easy and quick generation and testing of the entire cutting program.

Work area

X: 4,080 mm Y: 1,530 mm Z: 765 mm

A 360° B ±135° C ±12 mm

Axis speed

X, Y, Z: 100 m/min (trajectory: 175 m/min)

A, B: 1.5 rev/s

Accuracy*

Pa, Ps 0.03 mm (VDI 3441)

Fiber laser source

2,000 W – 3,000 – 4,000 W

*The accuracy of the piece depends on its type, size and pre-treatment, and the conditions of application.

Optimize your Prima Power machine

Prima Power 3D CAM

MACHINE PROGRAMMING

Cam application to program 3DLaser machine, provided by partner CENIT, in 3 license levels to support different use-cases

Tulus Analytics

PRODUCTION REPORTING AND MONITORING

Parts production and machine performance reporting

Related technologies

Related industries

Take a look at the other products and choose the best solution

Laser Next 1530-2130

3D LASER CUTTING MACHINES

The 3D laser system for automotive production

Laser Next 2141

3D LASER CUTTING MACHINES