Laser Next 1530-2130

3D LASER CUTTING MACHINES

The 3D laser system for automotive production

PERFORMANCE

Achieve unparalleled performance with the Laser Next 3D laser machine, ensuring the lowest cycle times and superior cutting quality. Engineered for excellence, this machine delivers first-class performance for the most demanding industrial applications

RELIABLE

Experience exceptional reliability with Laser Next, thanks to its advanced linear drives, dual head-protection system, and industry-standard components. Designed to operate with minimal downtime, it ensures consistent and dependable performance.

USER FRIENDLY

Benefit from intuitive, quick-learning, and fast programming capabilities, reducing changeover and setup times. The user-friendly interface allows for seamless operation, ensuring operators can quickly adapt and optimize productivity.

COMPACTNESS

Maximize your workspace with the compact design of Laser Next. Ideal for multi-machine configurations, it saves space and is easy to install, making it a versatile addition to any production line.

For automotive component manufacturers, achieving precision and efficiency in cutting stamped metal parts is essential. Prima Power's Laser Next is the definitive solution for this sector, specifically designed for the high-volume production of hot-stamped steel automotive components.

Every aspect of Laser Next has been meticulously engineered to maximize machine uptime and simplify maintenance, reducing nonproductive times and minimizing the need for specialized resources.

Recognized as the world’s fastest 3D laser machine, Laser Next is available in two sizes (1,500x3,050mm and 2,100x3,050mm) to accommodate varying production needs. It ensures exceptionally low cycle times and outstanding Overall Equipment Efficiency (OEE).

The space-efficient layout of Laser Next is ideal for both standalone and multi-machine configurations. It allows for up to three machines to be connected to a single magnetic scrap conveyor without the need for excavation work, enhancing operational efficiency.

The latest version of Laser Next is now even more productive and economical also thanks to the adoption of Siemens Numerical Control: Sinumerik One.

With an impressive increase in productivity of up to +13% compared to standard automotive production numbers, enhanced by the machine's high reliability and rapid capacity programming.

The proprietary Human-Machine Interface (HMI), built on the Tulus architecture, is designed to be intuitive and user-friendly, reducing the time operators spend on daily tasks by up to 15%.

Advanced Linear Motors: The linear motors on the main axes and direct motors with optical scales on the focusing head provide superior dynamics, accuracy, and reliability.

Robust Frame: Constructed from synthetic granite with state-of-the-art topology optimization, the frame ensures smooth and consistent machine movements even at the highest speeds.

High Precision Turntable: Equipped with a servo motor and absolute encoder, the high precision turntable guarantees top performance, reliability, and safety.

Innovative Focusing Head: The well-sealed, compact focusing head features Focus Position Control (FPC) and dual anti-crash systems to prevent damage. It doubles as a measuring tool, speeding up setup times and enabling on-machine part validation.

Laser Next stands at the forefront of 3D laser cutting technology, offering unmatched performance, reliability, and user-friendliness. Its advanced features and compact design make it an indispensable tool for automotive component manufacturers aiming for excellence and efficiency in their production processes.

Work area

X 3,050 mm Y 1,530 mm / 2,100 mm Z 612 mm

A 360° B ±135° C ±12 mm

Axis speed

X, Y, Z 120 m/min (trajectory 208 m/min)

A, B 1.5 rev/s

Accuracy*

Pa, Ps 0.03 mm (VDI 3441)

Fiber laser source

3,000 W – 4,000 W

*The accuracy of the piece depends on its type, size and pre-treatment, and the conditions of application.

Optimize your Prima Power machine

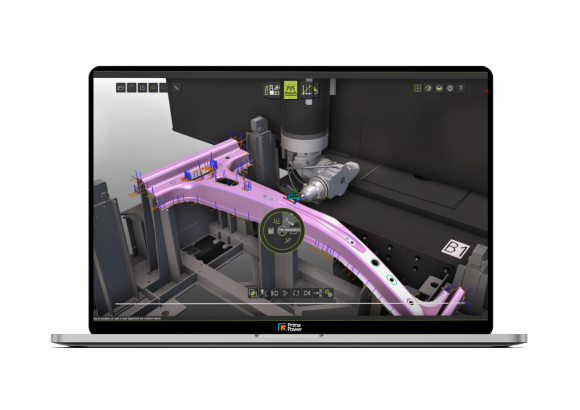

Prima Power 3D CAM

MACHINE PROGRAMMING

Cam application to program 3DLaser machine, provided by partner CENIT, in 3 license levels to support different use-cases

Tulus Analytics

PRODUCTION REPORTING AND MONITORING

Parts production and machine performance reporting

Related technologies

Related industries

Take a look at the other products and choose the best solution

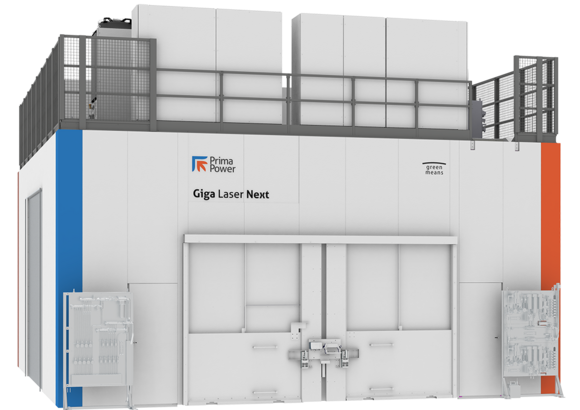

Giga Laser Next

3D LASER CUTTING MACHINES

Maximum productivity and minimum floor space for automated 3D laser cutting

Laser Next Core 2131

3D LASER CUTTING MACHINES

Versatility meets cost-efficiency in 3D laser processing

Laser Next 2141

3D LASER CUTTING MACHINES

The flexible solution with large working envelope and best-in-class efficiency

SUCCESS STORIES

Find out how a Prima Power Laser Next 1530 – 2130 machine took part in a company's success

Advanced Lasers Meet Diverse Needs of Tooling Group - Diversified Tooling

Advanced laser technology has been instrumental in making the four affiliated companies of the Diversified Tooling Group, Madison Heights, Mich., into a leading supplier of single-source manufacturing solutions to the automotive, heavy truck, defense, industrial equipment, power generation, rail, and foundry i