3D Laser Cutting: Revolutionizing Automotive Manufacturing

3D laser processing is transforming the automotive industry, significantly improving the quality of various automotive components, reducing costs and improving the environmental sustainability of production processes. This advanced technology allows for high precision and clean cuts, ensuring that each component meets rigorous quality standards.

In particular, 3D laser cutting is instrumental in producing complex metal components such as engine parts and bodywork components. These parts, which require the utmost precision and strength, benefit greatly from the accuracy and finesse of 3D laser cutting. By utilizing this technology, manufacturers can also achieve complex geometries if it’s necessary that are often challenging or impossible to create at reasonable costs with traditional manufacturing methods.

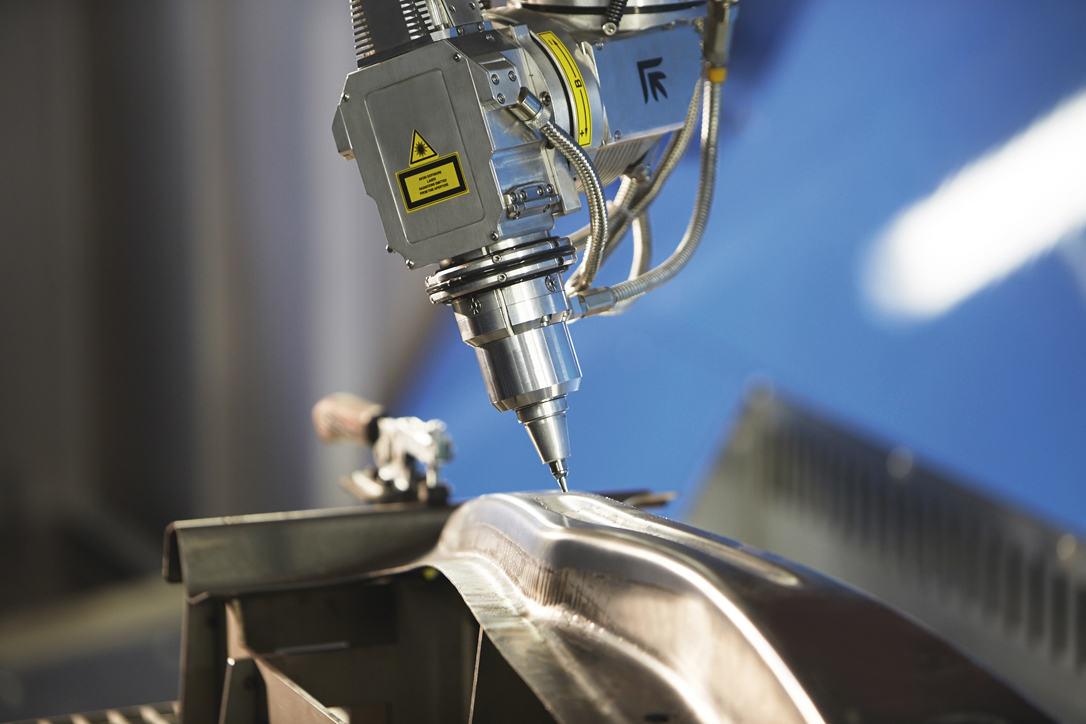

3D laser cutters employ a high-density heat source, creating precise cuts with a minimal heat-affected zone, which is crucial for the durability and performance of automotive parts avoiding severe deformations on mechanical components. The fact of heating a small portion of metal parts also ensures that changes in the behavior of the microstructure of the metal alloys used are limited as much as possible. The process is not just about cutting; it's about achieving perfect quality in every part. With CNC-controlled cutting heads, 3D laser cutters offer unparalleled design flexibility and complexity, essential for the diverse needs of the modern automotive industry.

Having the possibility to design the mechanical components that make up the complex system of a motor vehicle more freely allows designers of industries that use 3D laser processing to create innovative solutions, saving material and optimizing the weight of each part and therefore reducing fuel consumption.

This technology also significantly reduces production time, ensuring consistent part quality and faster turnaround times. In the automotive industry, time is of the essence, and 3D laser processing aids in maintaining the pace of production without compromising quality. The integration of laser cutters with robotic systems further enhances efficiency, especially in processing complex 3D parts.

Furthermore, in recent years, the automotive industry has increasingly adopted high strength steel (HSS) for many structural components, because these alloys are characterized by greater rigidity and allow weight - and therefore fuel consumption - to be reduced. The steels belonging to this family, precisely because of their excellent mechanical characteristics, are difficult and expensive to work with traditional chip removal technologies. For this reason, 3D laser systems are becoming increasingly widespread to produce structural mechanical parts for the automotive sector with HSS.

At Prima Power, we have specialized in developing 3D laser machines that can easily be integrated with automated production systems and that are highly appreciated in the automotive industry. Our focus on precision, speed, and versatility aligns perfectly with the industry's evolving needs. Our 3D laser solutions are designed not just to meet but to exceed the expectations of automotive manufacturers, continually pushing the boundaries of what's possible in automotive part fabrication.

Integrating 3D Laser Cutting with Industry 4.0 in Automotive Manufacturing

The integration of 3D laser cutting within the framework of Industry 4.0 is setting a new standard in the automotive industry. The evolution of laser technology, especially in the context of smart manufacturing systems, is a game-changer. 3D laser cutting systems, an integral part of this advancement, are proving to be more flexible, versatile, and adaptable to intelligent manufacturing processes.

This topic is explored in depth in an interesting 2022 study published in the World Journal of Engineering and Technology by professors Gyasi, Antila, Owusu-Ansah, Kah and Salminen entitled “Prospects of Robot Laser Cutting in the Era of Industry 4.0”.

The researchers underline that the integration of automated laser cutting machines with Industry 4.0 technologies means these systems can now be seamlessly incorporated into the manufacturing process, effectively enhancing automation and efficiency. In the study future perspectives of laser machines integration in automotive industry processes are also explored. According to the researchers this integration may be crucial for small and medium-sized enterprises in the automotive industry, which often deal with high-mix but low-volume production.

At Prima Power, we are deeply invested in the continuous research and development of new machines for metal 3D laser cutting. Our goal is to meet the specific needs of different clients in the automotive sector. We understand that each manufacturer has unique requirements, and our mission is to provide solutions that cater to these diverse needs. Our commitment to innovation ensures that our clients always have access to the most advanced 3D laser cutting technology, integrated with the latest advancements in Industry 4.0.

Sustainable and Cost-Effective 3D Laser Solutions by Prima Power

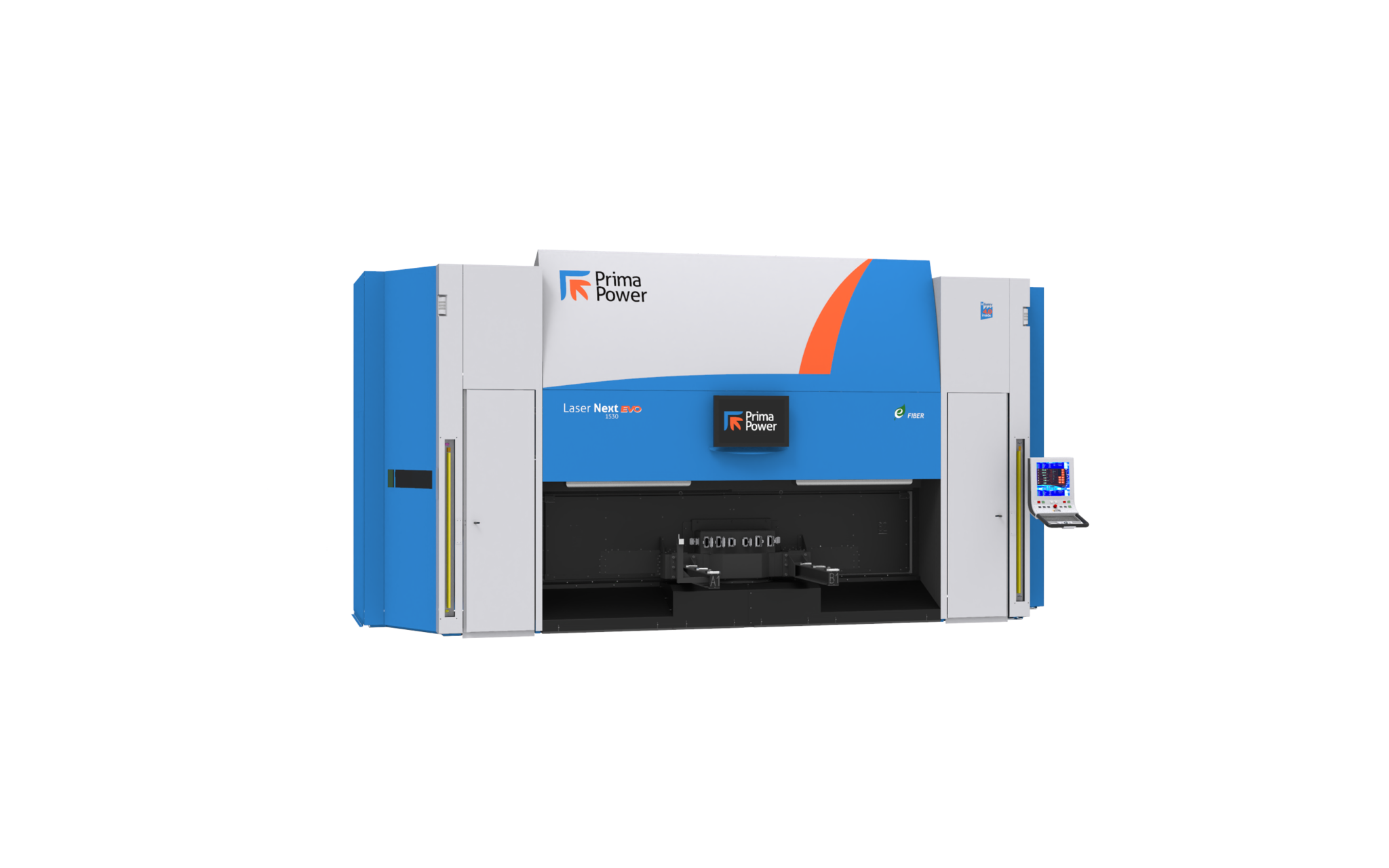

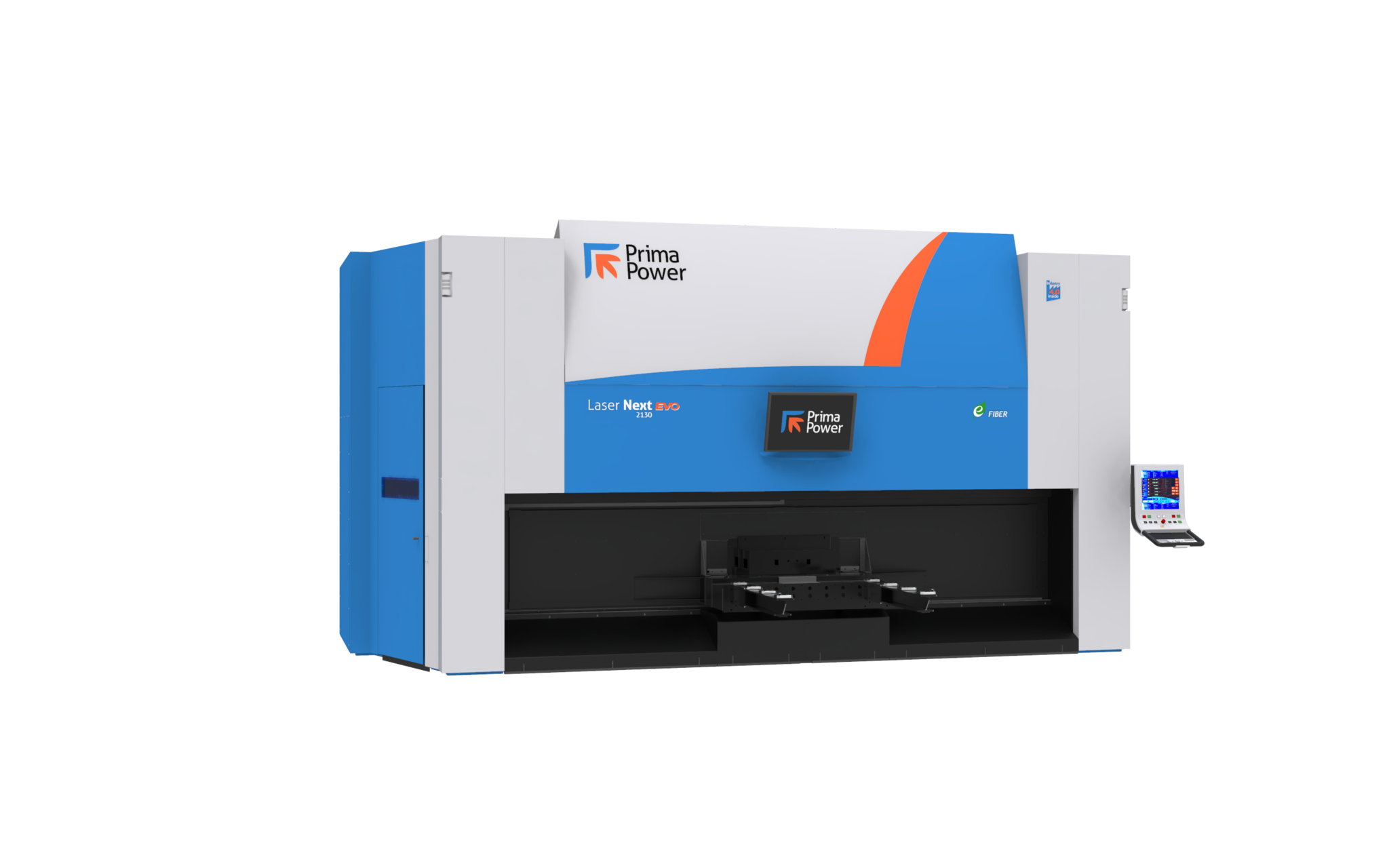

Prima Power's 3D laser solutions are at the forefront of combining technological excellence with environmental responsibility and cost-efficiency in the automotive industry. Our machines, such as the Laser Next® series, are designed to deliver first-class performance, specifically catering to the diverse demands of automotive manufacturing. In particular Laser Next® 1530 is optimized for meeting the demand of high-volume mass production for automotive parts, while Laser Next® 2130 it is a larger machine, suitable for processing larger components for the automotive industry, such as door rings, with levels of efficiency and productivity similar to the 1530.

At Prima Power, we understand that cost-effectiveness is crucial in the competitive automotive sector. Our 3D laser machines are designed to optimize the return on investment for our customers. By reducing the cost per part and maximizing efficiency, we help automotive manufacturers stay ahead in the market.

Our approach also prioritizes not only the productivity and efficiency of our machines but also their impact on the environment. We strive to develop solutions that contribute to sustainable manufacturing practices in the automotive sector. The precision and speed of our 3D laser machines result in reduced waste and energy usage, aligning with the ecological goals of the automotive industry.

We invite interested companies to reach out to Prima Power to explore potential collaborations. Our team is ready to discuss how our 3D laser solutions can enhance your manufacturing processes, align with your environmental goals, and improve cost-effectiveness. Together, let's drive innovation and success in your automotive production.