Prima Power, the pioneer of 3D laser cutting since the 1970s, proudly announces the launch of Giga Laser Next, a revolutionary leap in 3D laser cutting designed for the high-output demands of the automotive industry.

Prima Power unveils Giga Laser Next, a game-changing breakthrough in 3D laser cutting, tailored to the growing challenges of high-volume automotive manufacturing:

- Four heads. One giant leap: a world-first configuration allowing four laser heads in a cartesian machine to work simultaneously on a single part, delivering unprecedented spacetime efficiency.

- Made for the Giga Era: tailored for giga-factories and the rising use of giga presses, Giga Laser Next meets the evolving demands of automotive manufacturing.

- Ready for the line: fully integrable with lean automation, built for seamless, unmanned production lines.

A new machine for a new paradigm

With four synchronized laser heads cutting the same part and a dual-station layout that enables parallel loading and unloading, Giga Laser Next multiplies productivity while shrinking occupied space, unlocking new benchmarks in spacetime efficiency. Designed for giga-factories and the high-output production of high-strength steel (HSS) automotive components, Giga Laser Next is a response to the most urgent demands in the industry.

Why Go Giga Now?

Since the 1990s, High-Strength Steel (HSS) has revolutionized vehicle manufacturing by offering unmatched strength-to-weight ratios, enabling safer, lighter, and more sustainable vehicles. However, the very strength of HSS makes it unsuitable for conventional processes, creating a natural synergy with 3D laser cutting.

As automotive OEMs scale up to meet giga-factory throughput and EV demand, previous generation laser systems, while still effective in less intensive applications, struggle to keep up with the most demanding productivity requirements. Giga Laser Next is a Prima Power proprietary solution engineered to address directly the industry's most pressing needs: maximizing both floor space utilization and machine uptime for optimal production efficiency, minimizing direct labor, managing market volatility and multiple vehicle models, and ensuring short lead times.

The Prima Power legacy of leadership

From the trailblazing Optimo and Rapido to the renowned, ultra-fast Laser Next, Prima Power has continuously led innovation in 3D laser systems for the automotive industry. With nearly 50 years of experience and a global installation base, Prima Power shaped the standard – and are now redefining it.

Giovanni Negri, CEO of Prima Power and Prima Industrie Group, commented: “A new chapter in 3D laser processing begins today. Giga Laser Next embodies the essence of our strategy: Evolve by integration. We’ve integrated the productivity of four machines into a single compact unit, achieving what was previously thought impossible. This is not just a technological achievement, it’s a result of listening to our customers and translating their giga-scale ambitions into a tangible solution. I want to thank the Prima Power team for their dedication and incredible innovation capacity, as well as our partners and customers whose insights have been invaluable in shaping and optimizing this game-changing solution to meet their real production challenges.”

What Makes Giga Laser Next a Game Changer

Giga Laser Next stands out for three powerful reasons that directly address the demands of high-volume automotive production (typically >200,000 parts/year) while maintaining the flexibility to handle multiple part codes:

- +280% higher productivity per m²

- -75% average cutting stations required and production changeover time

- One piece flow, fully unmanned automation, complete integration into the production line

These benefits are made possible by a series of groundbreaking technical innovations. At the heart of Giga Laser Next is a unique configuration of four synchronized laser heads working simultaneously on the same part, enabled by advanced anti-collision system and a robust cartesian structure with high-performance retractable arms. The machine operates with typical idle time of around 2 seconds, thanks to parallel loading/unloading on one station, while the process is performed on the other. Its compact 10×10 m footprint is achieved by integrating ancillaries like laser sources and chillers on a mezzanine level, maximizing floor space efficiency.

Designed for full automation, Giga Laser Next supports embedded solutions for loading, unloading, quality checks, and marking, with the flexibility to connect directly to stamping or assembly lines. It also features an easy fixture change system, digital twin validation, and a machine architecture optimized for long-term reliability and minimal maintenance, making it ideal for high-volume production of automotive stamped and cast parts.

Don’t believe it? Just watch.

See the Giga Laser Next in action and experience this breakthrough technology. No AI tricks - just engineering magic and giga-productivity in real life.

Watch the video and Go Giga Now!

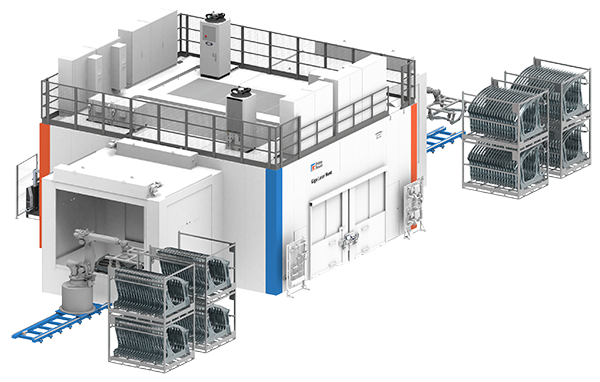

At the heart of Giga Laser Next is a unique configuration of four synchronized laser heads working simultaneously on the same part.

|

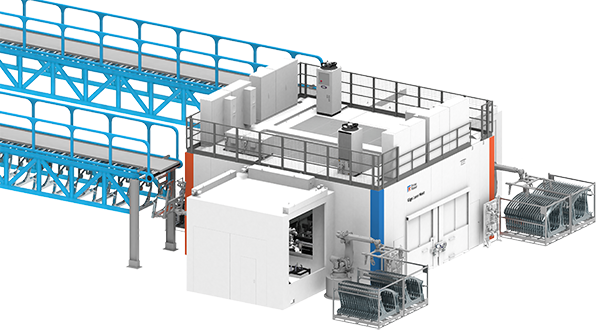

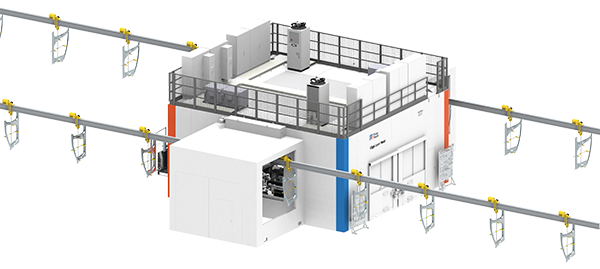

Giga Laser Next features maximum productivity and minimum floor space for automated 3D laser cutting.

|

Giga Laser Next with optical and mechanical quality check station enclosures.

|

Giga Laser Next with input and output racks on opposite sides.

|

Giga Laser Next with input and output racks on the same side and robots on rails.

|

Giga Laser Next with aerial conveyor and direct connection to assembly line.

|

Giga Laser Next with monorail system and direct connection from stamping to assembly.

|