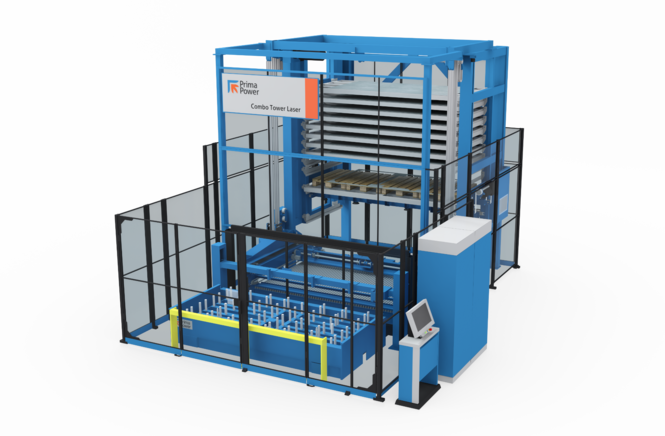

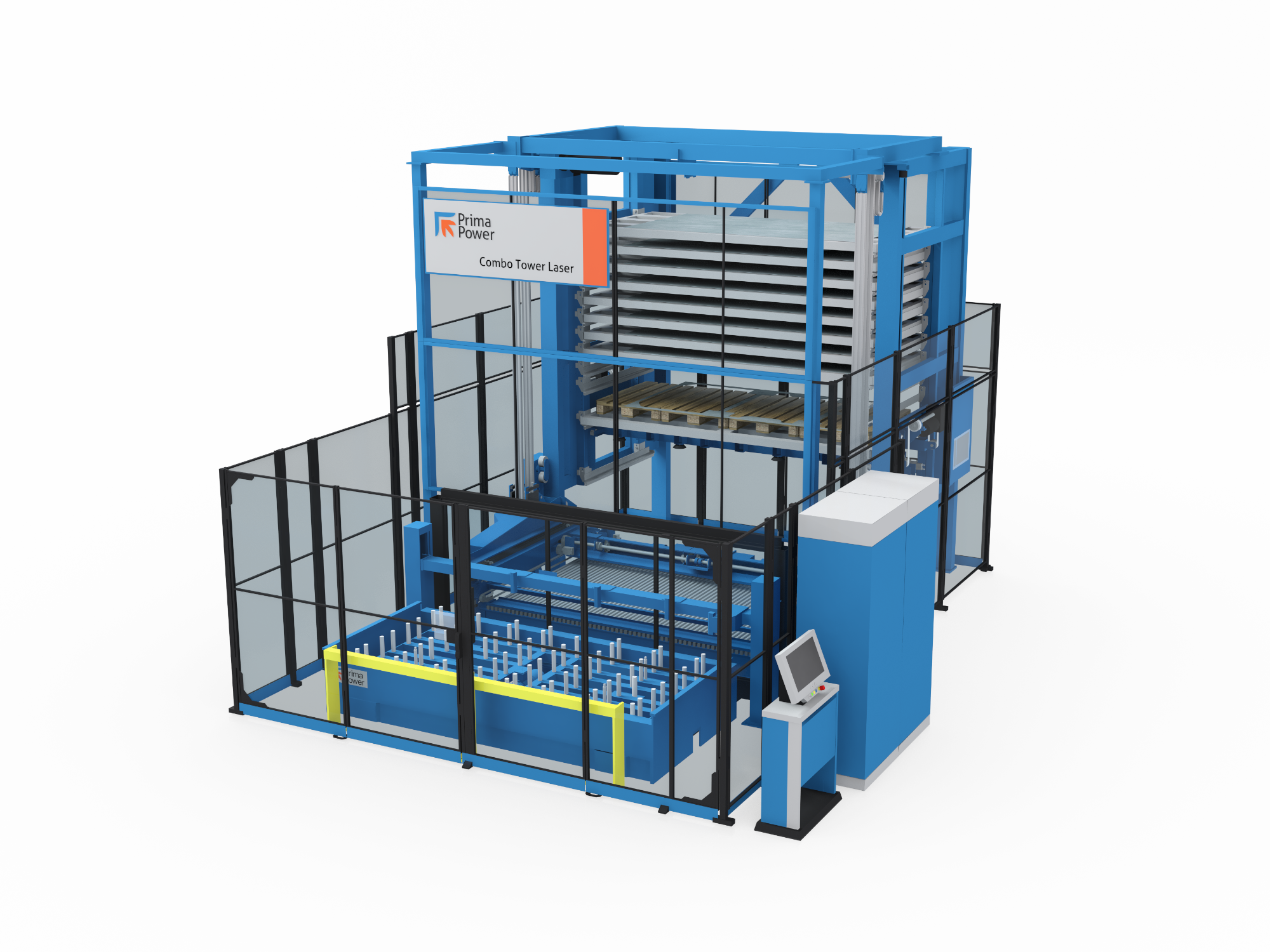

Combo Tower Laser

STORAGE SOLUTIONS

The key module to automate material flow with 2D laser machines

VERSATILE

Automatic material flow and large storage capacity

ECONOMIC

Saves space from the factory & provides higher productivity

COMPACT

Integrated loading & unloading for 2D Lasers

AUTOMATION 24/7

Perfect solution for lights-out production

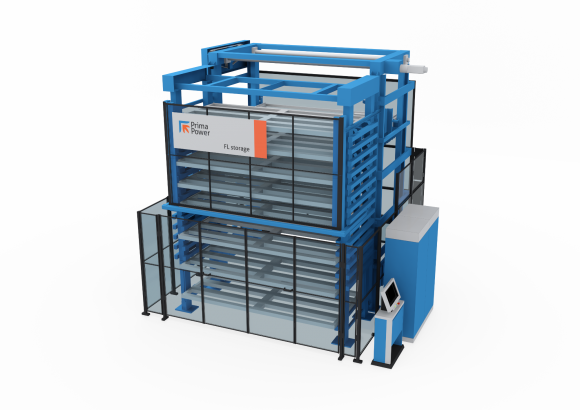

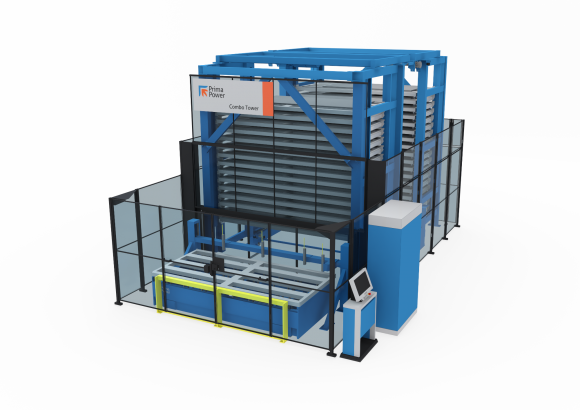

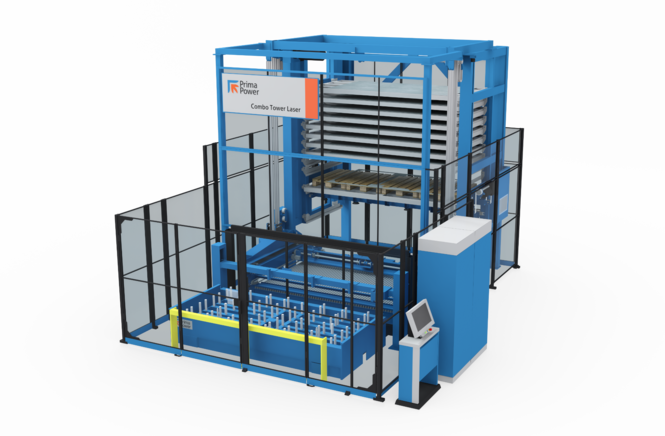

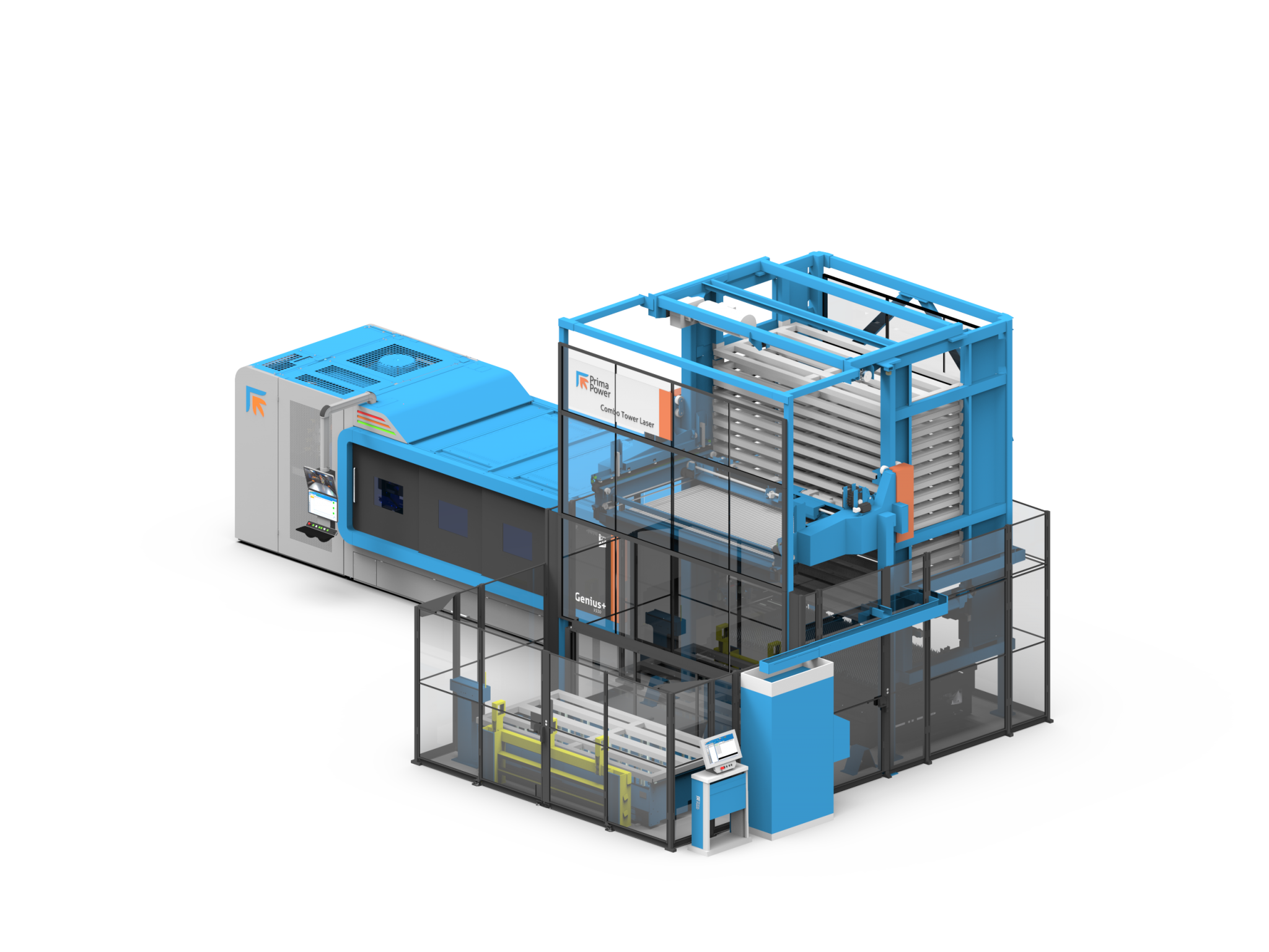

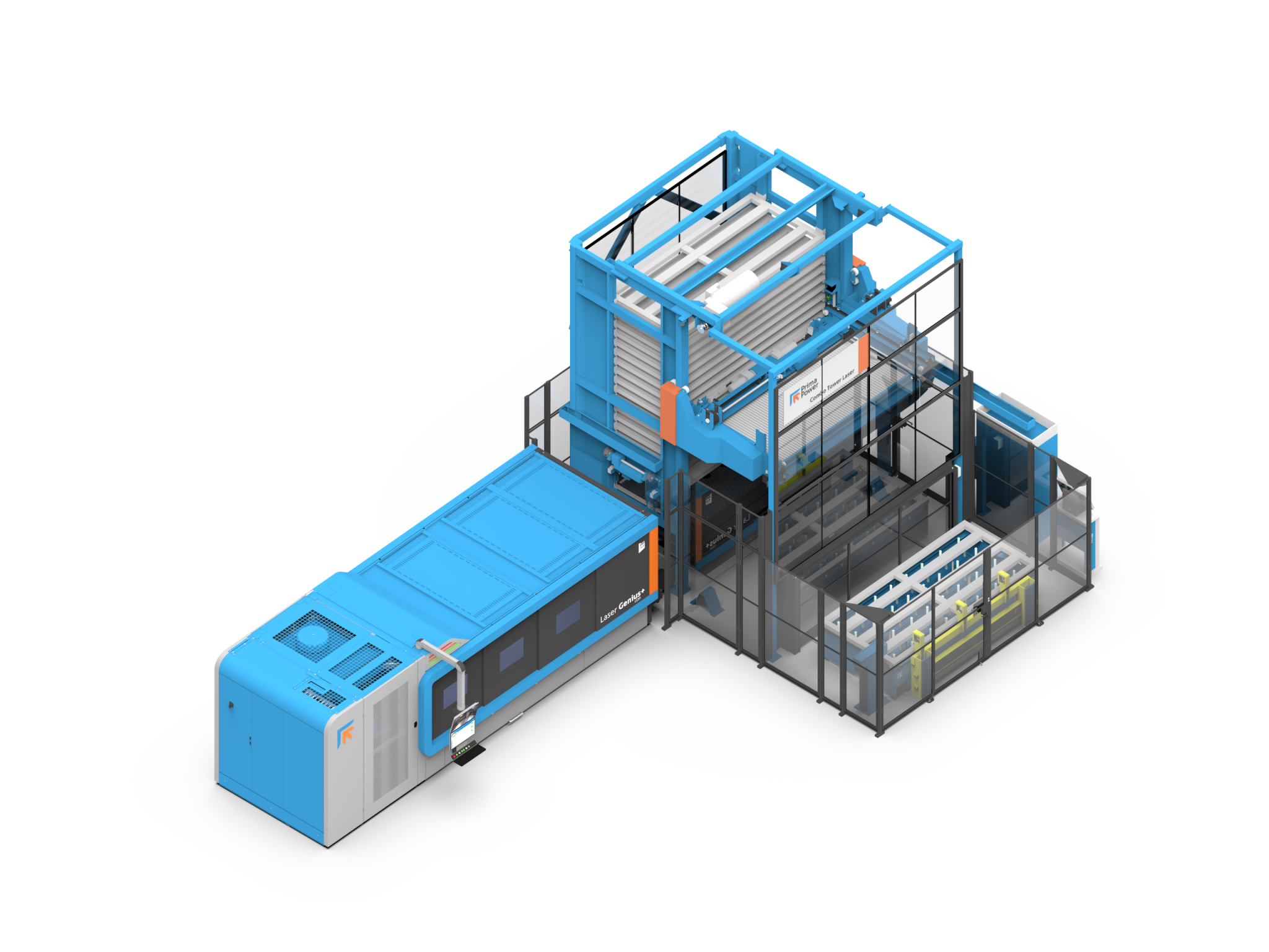

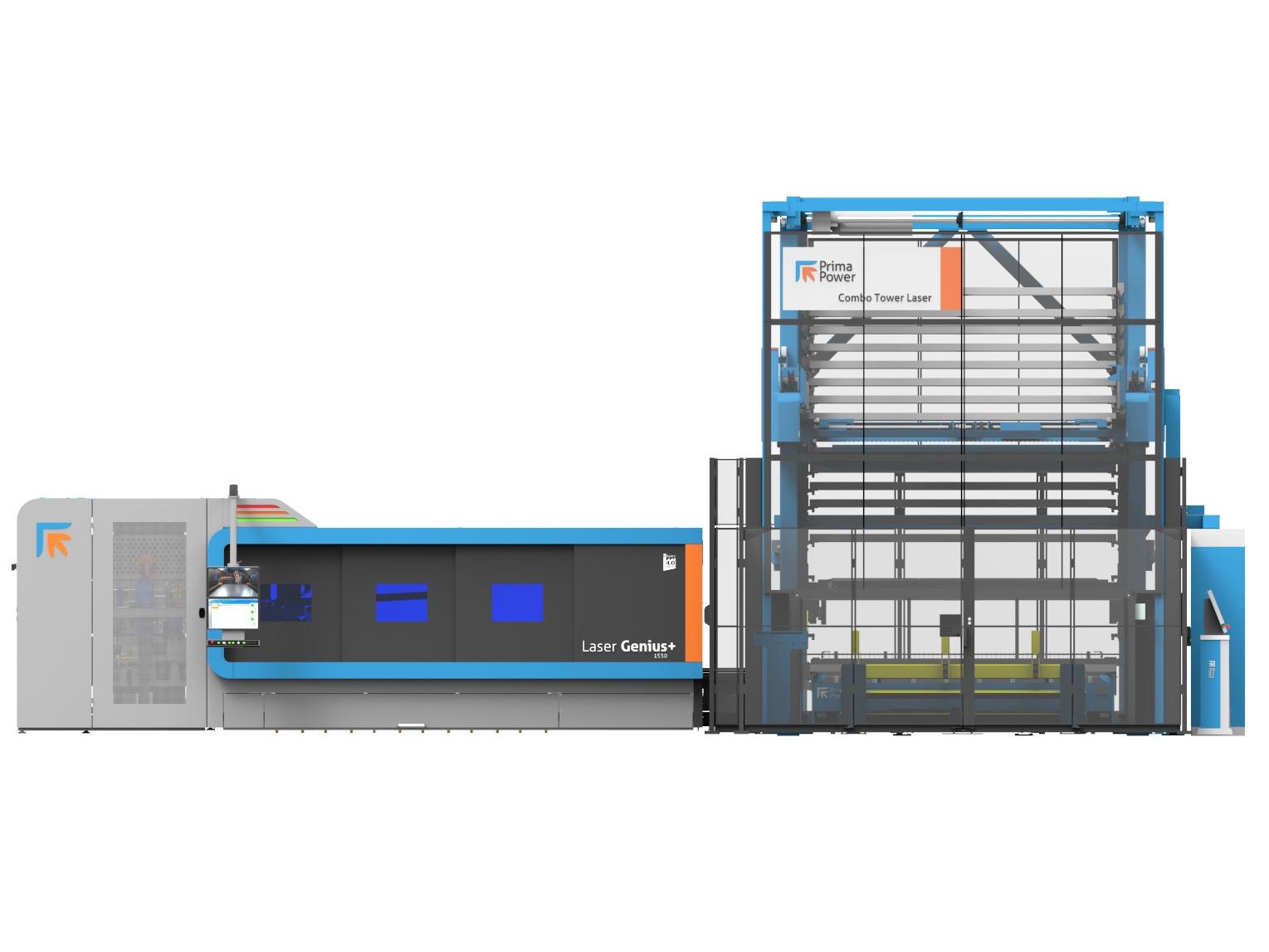

Combo Tower Laser is a flexible storage system with integrated loading and unloading features for 2D lasers.

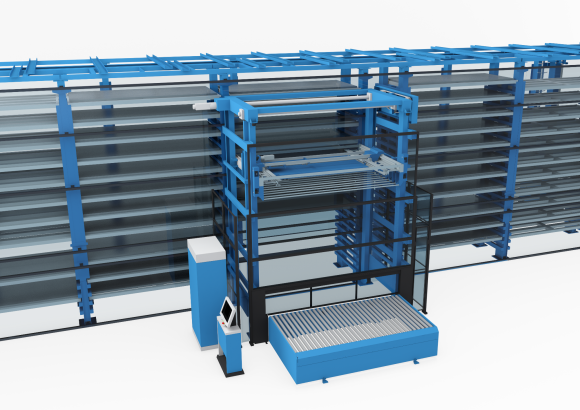

Combo Tower Laser is a key module to automate material flow. It makes different materials available whenever needed automatically and without delays; it can also serve as intermediate storage for ready cut components along with skeleton. Combo Tower Laser shelving unit structure releases space from the factory floor and increases production productivity. Integrated loading & unloading ensures a compact layout.

Combo Tower Laser also provides an optimal solution for lights-out production as capacity of available raw materials and unloading positions for skeletons can meet production requirements.

There can be one or two shelving units in the Combo Tower Laser and the height can be chosen according to needs. Model with one shelving unit is designed to serve one 2D laser.

When two shelving units are included in the Combo Tower Laser a second machine cell can be integrated as part of the system; depending on the required work stages and techniques, these can be selected from the wide range of Prima Power solutions for punching, laser cutting, integrated punching / shearing and punching / laser cutting.

Related technologies

Take a look at the other products and choose the best solution

Fast Loading storage

STORAGE SOLUTIONS