The company launched the first computer designed for industrial use in 1996. Three years later, it released the first computer compliant to defense industry standards.

Today, the operation is in Savonlinna, Finland, from where the company offers its customers the mechanical solutions and sheet metal products it designs and manufactures. CEF is a truly domestic partner whose values strongly include quality, cooperation and high professionalism.

"The company is known for quality products and services, flexibility and reliability. In the future, we increasingly want to be a value-adding partner whose product development expertise is available to the customer from the outset. For example, making products lighter with calotte cell structures is one of our significant strengths,” says CEO Teemu Vastamäki.

Recently, the company's largest production volumes have been in various pulp and paper industry products, engine shields for machine manufacturers, and computer frames and casings for industrial use.

"In addition, many products are manufactured for the sawmill industry, as well as shipping boxes for parcel handling machines. Although the company's main market is Finland, its customers almost always operate globally,” says Vastamäki.

We actively develop our products in cooperation with customers. The idea of the final product or the need comes from the customer, and then we start the development work together based on the customer's requirements. Our professionalism is then to implement it cost-effectively and sensibly in terms of fabricability.

THE LONG ROOTS OF COLLABORATION MADE THE INVESTMENT DECISION EASY

"CEF's cooperation with Prima Power began as early as 2000, when the first press brake came to the factory. As a continuation of this, the company acquired the LPe5 laser punch in 2003. Finn-Power was also heavily involved when the company developed calotte cell technology. The test cells were manufactured at the Finn-Power plant, and this also helped to strengthen cooperation between the companies and confirmed that LPe5 was exactly the right machine for CEF's needs. The cooperation has continued seamlessly during our various product development projects, for example, and CEF has always received the necessary assistance from skilled Finn-Power experts, whether it concerns tools or other development needs. Our close cooperation will continue,” Vastamäki says.

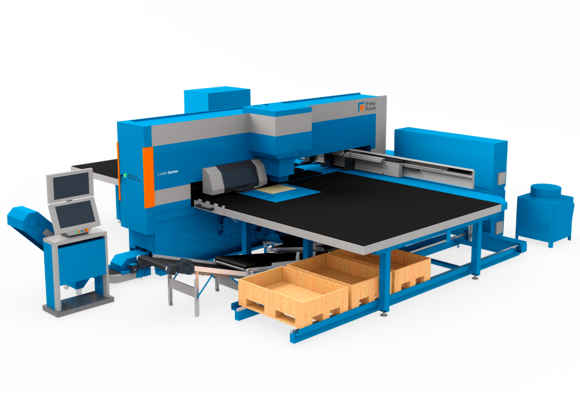

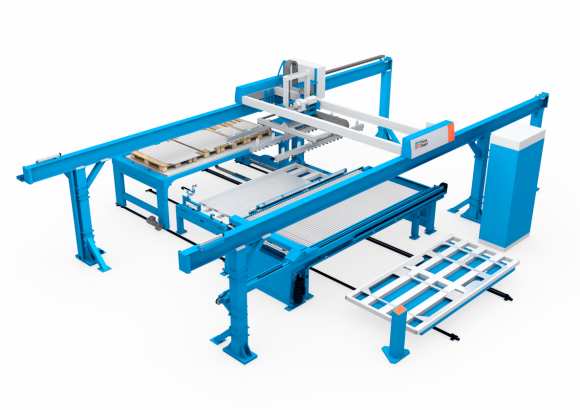

As the latest investment, the company ended up with Prima Power’s Combi Genius, which combines laser cutting and punching.

"The old combination machine had reached the end of its life and it was necessary to get a new one. We decided on Prima Power because the product was familiar and known to be of high quality. Prima Power's maintenance services, which were found to be good and functional, also weighed in the decision,” says Henri Hiltunen, Head of Production.

Experiences with Combi Genius have been positive.

"The cutting speed of the laser unit has almost doubled in comparison with the old LPe5, and in addition, the modern laser enables quick changes in settings when there is a need to change the material thickness, Hiltunen continues.

"The LSR robot on the unloading side was a positive surprise. The robot makes the operator's daily work easier because it can sort a surprisingly wide range of cuttings. In the future, we want to increase the use of the marking device, which will also improve the traceability of the cuttings,” Hiltunen says.

"Considering the age of the old machine, the new one has brought certainty and quality. With the new machine, the nesting program was renewed, but that was only a good thing. At the same time, nests were revised in a more efficient direction. After good experiences and learning new things, we have reached a very good production speed,” Hiltunen continues.

FUTURE VISIONS

The future of Control Express Finland Oy looks good, and the direction is profitable and controlled upward growth. In addition to the right investments, growth will be supported by human resources and adequate facilities.

" Now, the lack of space is a great challenge, but things tend to work out,” said Vastamäki, CEO.