Paramount Components

Job shop powers through bending bottlenecks

Paramount Components employs semi-automatic panel bender to manage time, talent crunch

Ever since Paramount Components opened its doors as a sheet metal fabrication job shop in 1988, the company has never shied away from a challenge. In fact, challenging jobs have become Paramount’s niche in the market.

“We typically take on the more difficult work,” explained Jamie Palliardi, owner. “We tend to stay away from the simple longer-run jobs, such as 10,000 brackets with one 90-degree bend. Our niche is doing the more difficult jobs ... the jobs that the competitors will shy away from because of multiple complex bends that all have to fit together or multiple part assemblies that all have to come together and work within very tight tolerances. My dad Mark founded the company and always thought that we would have a much stronger workforce if we gave them a challenge. So we always go after the more difficult work.”

Today the company ships prototypes and custom sheet metal parts and assemblies across North and South America, Asia, and Europe from its plant in Abbotsford, B.C. Paramount serves such diverse industries as telecommunications, electronics, medical, dental, printing, military, architectural, and automotive.

To ensure consistent high quality and on-time delivery, Paramount has always put a premium on innovation and state-of-the art fabricating equipment. And most recently the search for more efficient bending was a key consideration.

BENDING BOTTLENECKS

“Bending is one of the hardest departments for us to staff,” said Palliardi. “It takes a great amount of time to learn how to do forming on a press brake properly. It can take years to properly train a good press brake operator to have the know-ledge to form all the different types of parts we process and be proficient at their job. So it was often the first area of our facility for bottlenecks in production to occur. This was especially true when bending large parts, such as cabinet doors, that need two press brake operators to handle. We were doing long runs at the time and were worried about our employees’ fatigue from having to lift these heavy parts all day. That was one of the main reasons we started to look for alternatives to press brakes.”

Palliardi and the Paramount team first considered robots to be the answer but came to see them as “finicky.” “They needed a great deal of setup time,” he said. “There are literally thousands of parts that we form, and most of them are smaller-run sizes. We would have spent more time setting it up, finding specialized jigs or how to grip the part. The robot did not provide the versatility we needed.”Panel Bender Introduction Paramount’s production manager suggested they take a look at panel benders, so the team began online research into a number of options. The company was looking for a supplier with an established panel bender and that knew the technology well. They ended up choosing the Prima Power BCe Smart.

“One of the deciding factors was serviceability,” said Palliardi. “When we put our feelers out in the market and talked to other people in the sheet metal world, the feedback was that Prima Power would be better able to service us in B.C. than its competitor.”

The BCe Smart was installed in August 2018.

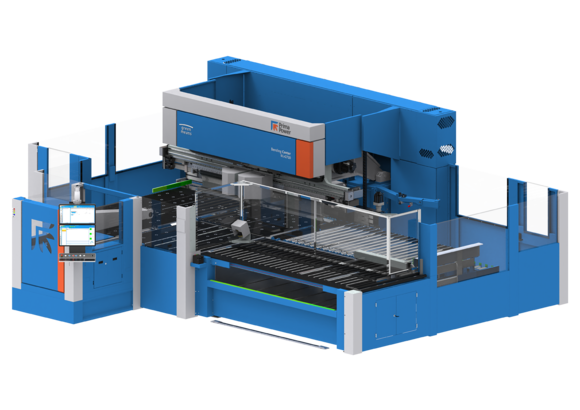

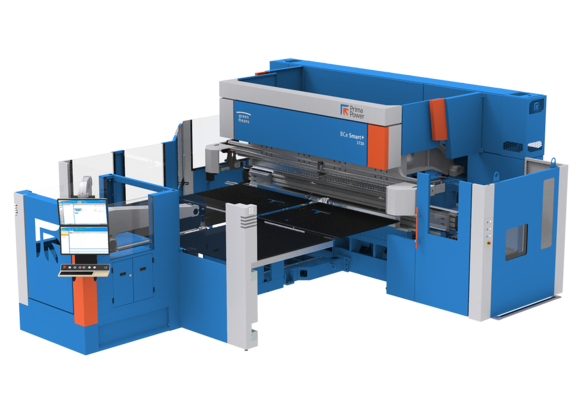

The panel bender, which uses servo-electric bending technology, is suitable for medium production volumes as well as for low volumes and lean production. The panel bender is designed to allow loading and unloading in a single sequence. The machine also does not require skilled operators. Because of its bar code reader and ATC system, setup is automatic; it takes place in masked time and activates dynamic production queues.

There are no physical barriers for manual loading. Warning lights and acoustic signals help the operator to synchronize the loading and unloading, and an additional interactive display guides the operator in the working phases to be carried out, for example, the orientation of the pieces. The machine also can be set up to integrate with a robot for automatic loading and unloading.

FLEXIBILITY IN ACTION

“We originally purchased the BCe for large-sized parts and high volume,” said Palliardi. “Today we are using it more for smaller runs. In a day we put through 10 to 12 different jobs as opposed to before, when one job would take four to six hours. Now, we run a lot more parts, but smaller runs. Being a job shop, this can change over time, and the panel bender can handle whatever size run we need for our customers’ demands.”

Today Paramount keeps all its highly skilled forming team on the company’s press brakes. “We have hired new employees that don’t require as much training to run the BCe Smart,” explained Palliardi. “I can also run the bender through our three shifts. I can have a guy that started last week, and show him how to load and unload it, and that person can keep the machine running. We are trying to put everything on the panel bender that will fit because it will be processed faster than on the press brake. Because we have all the tooling in the machine, I would be surprised if our longest setup would take as long as five minutes. We can quickly move from one part to the next—the press brakes don’t even have a chance to compete.

“Another big selling point for us was that with the panel bender you don’t have to remove any tools. We buy a press brake and then we have to spend a lot of money on tooling. As of today, we run around 20 per cent of all our parts on the panel bender. Our goal is to raise that up closer to 40 per cent in the near future. To date, we’ve never had a backlog at the machine because it is so quick. On a Monday it may look that we have quite a bit of panel bending to do. Then I will recheck things on Wednesday and it’s all done and moved through the shop, and there is no queue by it.”

STAYING ON THE LEADING EDGE

Paramount was the first company in B.C. to purchase this brand of panel bender. “Paramount has always prided itself on being a company that was on the leading edge of technology,” said Palliardi. “We pride ourselves on quality work ... and to do a quality job, we need to have the very best equipment. The panel bender has also helped us in quoting jobs because we can quote the exact times things are going to take, and we can fine-tune what the pricing is going to be as well. And as a job shop, we face constant pressure from our customers to decrease our lead times. Anything that we put through the bender goes through smoothly. We can clear things through production much quicker.”

The BCe has also helped us in quoting jobs because we can quote the exact times things are going to take...and we can fine tune what the pricing is going to be as well. And as a job shop, we face constant pressure for our customers to decrease our lead times. Anything that we put through the BCe bender goes through smoothly. We can clear things through production much quicker.

Are you looking for a similar solution for your company? Find it here

BCe Bending Centre

PANEL BENDERS

Flexibility at your service semi automatic panel bender combining flexibility and productivity

BCe Smart+

PANEL BENDER