From diesel and gas generator sets to lighting towers and hybrid generators sets ready to be incorporated into solar power systems.

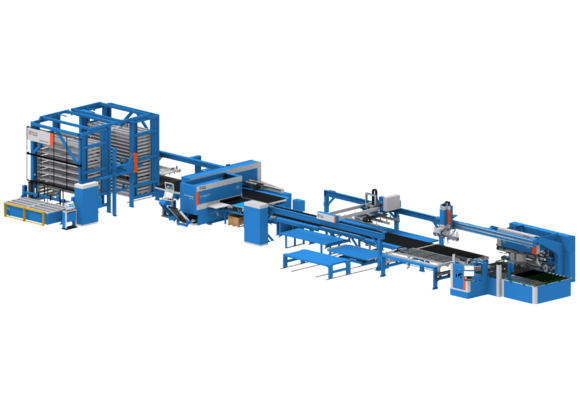

Founded in 2006, HIMOINSA China (HCN) is located Changzhou, Jiangsu Province. It covers a total of 60,000m², with 200 employees and a yearly productive capacity of 12,000 units. In 2007, HCN purchased a Night Train FMS system from Finn-Power (which was merged by Prima Industrie and is now named Prima Power) for the massive production of standardized products. “At that time, standardized products were quite common. With the huge storage volume provided by Night Train storage, we can store many raw materials for large scale production. So we can get, let’s say 1000 sheets at the same time. It saved a lot of time for the loading and unloading operation and greatly increased our efficiency. After 13 years, it still works well.” explains Miguel Utrillas, General Manager of HCN.

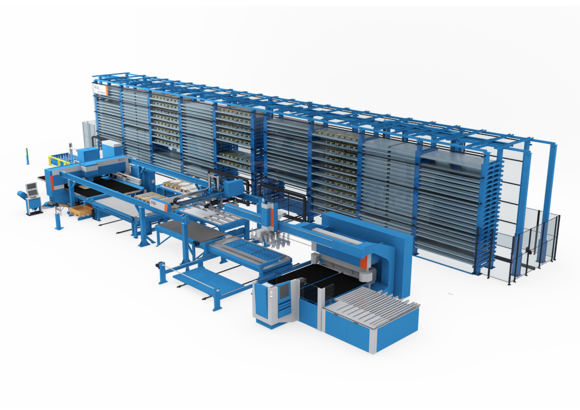

Meanwhile, HCN had to purchase many fabrication parts from external suppliers before another new PSBB line was put into production in 2019.

HIMOINSA products are widely used in a wide range of applications, such as events, Oil & Gas, construction, mining, IPP, water treatment, also as temporary stand-by power for shops, hospitals, hotels, data center, telecommunication, rental etc.

The group is producing more units in China year by year, and offer generator sets from 3 to 3,000 kVA and lighting towers of various specifications. They are in a highly competitive industry in China and their customers have special customized needs for each project.

“In order to have a competitive advantage over the local and overseas competitors, we are manufacturing all the components of a generator set in house, including chassis, fuel tanks and complete canopies.“ added Miguel Utrillas.

During the past decade, after the traditional industries like Machine Tool, Real Estate and related Iron & Cement, Textile, the rapidly growing industries like Semiconductor, Airport, Data Centers, 5G, AI, IT, Banking in China continue to stimulate the economy. The revenue from APAC (without India and Central Asia) has increased from less than 10% of global revenue in 2013 to 21% in 2018.

So HCN needed a new, more flexible manufacturing line to respond to the increasing customer requirements for different specifications and quantities.