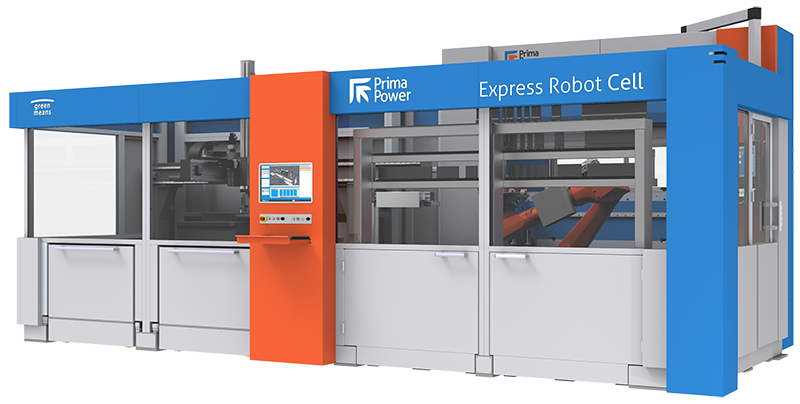

Compact and flexible robotic bending solution, unveiled for the first time worldwide at Blechexpo, ready for fully automated production with seamless FMS and AGV integration

Among the key highlights of the stand is the Express Robot Cell, a new compact robotic bending cell making its world premiere. This flexible and fully automated solution integrates an eP0520 servo-electric press brake with 50 ton of bending force and a 2,320-mm bending length, a 6-axis anthropomorphic robot and a 3-axis Cartesian loader in a reduced footprint, making the cell suitable even for space-constrained environments. Its compact layout allows for fast movement execution and low cycle times, resulting in high productivity. The two robots work in parallel, further enhancing the system efficiency.

The Express Robot Cell is designed for maximum flexibility and can handle a wide variety of part geometries with just two universal grippers equipped with suction, magnetic, and clamping technologies, as well as one automatic tool-changing gripper. The entire cycle - gripping, centering, bending, overturning, and unloading - is autonomously managed for optimal efficiency.

But what truly sets this solution apart is its connectivity and expandability. Express Robot Cell can be integrated with FMS storages, such as Prima Power’s Night Train, enabling continuous, unattended production. The stand-alone version can be easily upgraded to a connected solution, with automated loading from storage systems and unloading to Automated Guided Vehicles (AGVs).

The system is built on a plug-and-play integrated metallic platform that houses the press brake and robot with peripherals in two main components, ensuring fast transport and easy installation.

This solution is the ideal choice for sectors like appliances, HVAC, automotive, metal furniture, and industrial components, handling small- to medium-sized parts, from simple to highly complex geometries. Leveraging the know-how of the Prima Power Robotics Integration Unit, the new system is designed to grow with the customer from a stand-alone unit to a fully connected production cell.