BOTTLENECKS OPEN WITH NEW PRODUCTION EQUIPMENT

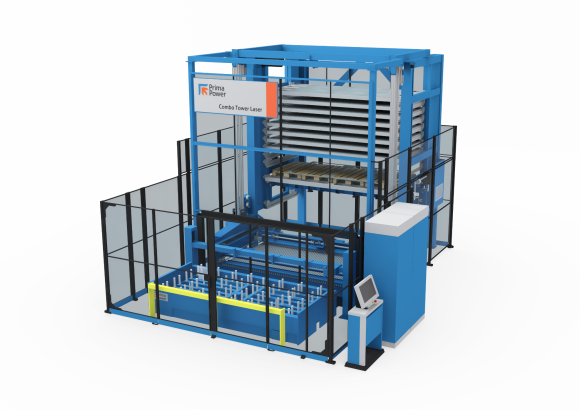

Toni Lehtinen, a laser operator at Lojer, discusses the company's new 6kW Platino Fiber 2D laser, which is integrated with an approximately 40-position CTL storage. This setup is complemented by an LST unloading robot and an unloading conveyor belt, which simplifies manual unloading. In addition, the company utilizes two press brakes of different sizes.

Helenius recalls how in 2005 Lojer acquired the first Finn-Power press brake, which left behind positive experiences. The press brake recently began to feel small and became a bottleneck in production. We started exploring the purchase of a new press brake, and it became apparent that the old 2D laser was also reaching its capacity limits and nearing the end of its lifecycle.

CHOICE IN FAVOUR OF A DOMESTIC PARTNERSHIP

“Procurement is not only about efficiency and cost, but also about company values. Lojer values domesticity and long-term partnership, which is why the company's choice was Prima Power”, says Helenius.

“The use of automation is a key part of Lojer's manufacturing process, especially in unmanned operation. The sheet metal storage unit feeds in new sheets and removes used ones, while the unloading robot handles cut parts”, says Lehtinen.

Cutting speeds at Lojer have increased tenfold, and at the same time productivity has grown by 25%. This means significantly larger volumes of parts are being processed more efficiently.

RELIABLE COOPERATION AND MAINTENANCE SERVICES

Lehtinen highlights how Prima Power's maintenance and support services have worked seamlessly. The response time to problems is short and assistance is available immediately through remote connections when needed. If necessary, Prima Power service technicians arrive quickly on-site.

Prima Power's flexibility has been a positive surprise to Lojer. Especially during the commissioning phase, the company provided support even in the evenings.

“I recommend Prima Power to everyone. From the very beginning, cooperation has been smooth and natural, and Prima Power has been a reliable partner who has delivered what was agreed on as promised and within the agreed schedule,” Helenius concludes.