IMPEA | Technological innovation at its best

IMPEA utilizes the most advanced technologies and collaborates with renowned partners, such as Prima Power for 2D and 3D laser cutting, to ensure high-quality standards, operational speed, and maximum flexibility in sheet metal processing.

What started as a small job shop soon grew into a metalworking company that, in 2024, had a turnover of 15 million euros. The company produced 2.9 million body and light carpentry components, processed 3,000 tons of sheet metal, and maintained a storage area of about 60,000 m². IMPEA was originally founded in 1963 as a manufacturer of bumpers and body parts for the luxury car industry. Over the years, IMPEA has become the gold standard of excellence in sheet processing through its constantly evolving fleet of machines and solid partnerships with leading national and international car manufacturers. The company has approximately eighty employees, spread between the production facility in Piadena Drizzona and the administrative headquarters in Cremona, within the Lombardy region of northern Italy. Today, the company leads the agricultural mechanization sector, manufacturing cabins, hoods, platforms, and other sheet metal accessories for tractors and other work vehicles. Its capabilities are extensive, including stamping, cutting, forming, deep drawing, bending, welding, assembly, and every other step in sheet metal processing that leading companies in the industry could possibly need. “IMPEA began in August 1963 with an idea from my parents,” says Emiliano Bosisio, who runs the company with his children: Francesco, the CEO, and Marta, the Human Resources Manager. “It is the story of a family business that began over sixty years ago and is still going strong today, into its third generation. Our success is fueled by our unwavering commitment, advanced technical skills, and investment in new technologies, with a focus on staff training.”

A philosophy centered on innovation

IMPEA's philosophy is rooted in the continuous development of its products and processes. By offering advanced technologies and efficient standardization of work, IMPEA has successfully secured a market niche characterized by high customization. “Technological innovation is a pillar of our industrial approach,” explains Francesco Bosisio. “We are continuously investing in state-of-the-art solutions to guarantee superior quality standards, operational efficiency, and optimal flexibility, even for highly intricate machining processes. Our philosophy, combined with our commitment to excellence in partnership, brought us to Prima Power, whose solutions have further enhanced the quality of our products.” The collaboration between IMPEA and Prima Power has been ongoing for several years, leading to the establishment of a substantial fleet of machines with CO2, 2D, and 3D fiber laser cutting systems. “The first machine we ever purchased from Prima Power was a Platino,” explains Francesco Bosisio. “It was a 2D CO2 laser, and we later also added a 3D laser. More recently, we acquired fiber lasers.” IMPEA's laser cutting process includes various machines, such as Prima Power's Laser Next 2141. This flexible solution has a large working area and combines high performance with excellent cutting quality. “The Laser Next 2141 plays a key role at IMPEA. It uses three-dimensional laser cutting technology on body parts that come from sheet metal processing, and its fiber-cutting technology guarantees higher speeds and quality than other laser machines.” Three-dimensional cutting processes form a core part of the Cremona-based company's business, enabling it to remain competitive while avoiding the need for significant investment in stamping tools, which would not be sustainable given the low volumes typical of the specialized machinery sector. Furthermore, thanks to 3D laser cutting technology, IMPEA can meet the needs of customers who, in recent years, opted for plastic materials but would prefer sheet metal for its strength and quality. President Emiliano Bosisio emphasizes that “IMPEA owes its success to its strategic investments in cutting-edge technologies and the support of trusted partners such as Prima Power.”

The perfect blend of flexibility, speed, and precision for optimal cutting

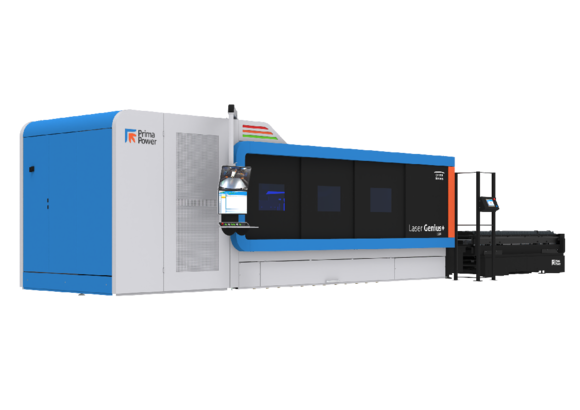

Another key machine for IMPEA is the Prima Power 2D Laser Genius+ 1530 laser cutting machine, which was installed in 2021. It has a 6-kW source and is equipped with an automated Combo Tower Laser storage system and a third table. “This is a very fast machine that produces high-quality cuts,” explains Francesco Bosisio. “We run it over two or three shifts, even unmanned, unlike other cutting machines that typically run on one single shift.” The Laser Genius+, an ideal solution for complex parts and a variety of materials and thicknesses, is a flexible, fast, and accurate solution. The machine's high-dynamic transmissions allow it to accelerate to 2.8 g and reach speeds of 180 m/min. Meanwhile, the gantry architecture ensures high levels of stability. The Laser Genius+ at IMPEA is complemented by the Combo Tower Laser, a versatile storage solution which integrates automatic loading and unloading functions to ensure materials are readily accessible. The Combo Tower Laser can also serve as a temporary storage solution for components that have already been cut. A third table facilitates additional loading and unloading during idle time, which makes it suitable for handling more delicate workpieces or for sending a single sheet not in the Tower for cutting. This solution also enables the future installation of a PSR robot for unloading, palletizing, and stacking individual parts.

Process digitization for more efficient management

At the core of IMPEA's activities is production process management, a skill developed over time through the reorganization of spaces, the automation of flows, and the adoption of lean manufacturing principles to optimize all processing steps and reduce waste. “IMPEA places significant emphasis on the digitization of processes,” Francesco Bosisio explains, “That's why all of our machines need to be interconnected according to the Industry 4.0 protocol. Our digitization process began with the MES in 2003, or rather, with my thesis, which allowed us to start tracking production timelines and collecting data to analyze costs.” IMPEA has thus transitioned from a critical issue related to the lack of a data collection history to a much more precise and efficient process management system. “We started using the MES with stamping,” the CEO continues, “and then extended it to all of our company departments with dedicated Advanced MES 4.0 stations.” In this particular instance, Prima Power's 3D and 2D lasers are interconnected solutions that communicate with the system. Data for the MES is taken from the ERP and transferred to a business intelligence platform. Reports are then generated on various topics, including personnel analysis, time and method analysis, punctuality, the asset and liability cycles, budgeting, and reporting. Additionally, totems displaying strategic data have been installed throughout the company so that staff can compare their performance to that of various departments and access economic data and other company-related information.

In 2024, IMPEA participated in a digitization audit sponsored by the Digital Innovation Hub of Confindustria (General Confederation of Italian Industry). The goal was to assess the company's level of digital maturity against benchmarks in the metalworking sector. The audit provided a detailed map of the processes that had already been digitized, areas that needed improvement, and opportunities for development. The results confirmed IMPEA's high level of digital maturity, placing the company among the most advanced with an overall score of 3.89 out of 5.00. “The data that emerged provide concrete guidance for continuing the digital transformation process and strengthening an increasingly interconnected, efficient, and data-driven industrial structure. A strategic check-up to measure our level of maturity,” concludes Francesco Bosisio.

The importance of diversification

In a highly competitive and demanding market, IMPEA's decision to adopt cutting-edge technologies, such as those offered by Prima Power, was pivotal. “Our future market diversification strategy will allow us to expand our operations beyond the Italian borders to meet the needs of foreign customers as well,” the CEO points out. “We have successfully expanded our reach and recently achieved a significant international milestone by directly penetrating the French earthmoving market.” Access to new markets is a major challenge that IMPEA is determined to overcome. This objective aligns with others, including the continuous improvement of quality and productivity, as well as the potential internalization of certain processes, such as painting, to streamline the management of key operations.

IMPEA owes its success to its strategic investments in cutting-edge technologies and the support of trusted partners such as Prima Power.

Are you looking for a similar solution for your company? Find it here

Laser Next 1530-2130

3D LASER CUTTING MACHINES

The 3D laser system for automotive production

Laser Next 2141

3D LASER CUTTING MACHINES

The flexible solution with large working envelope and best-in-class efficiency

Laser Next Core 2131

3D LASER CUTTING MACHINES

Versatility meets cost-efficiency in 3D laser processing

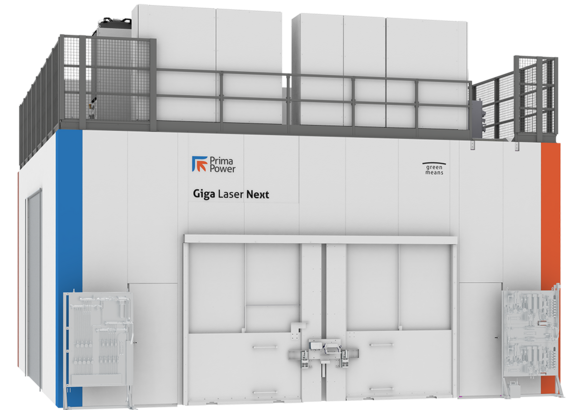

Giga Laser Next

3D LASER CUTTING MACHINES

Maximum productivity and minimum floor space for automated 3D laser cutting

Laser Genius+

2D LASER CUTTING MACHINES

Prima Power laser machine faster, more precise, cheaper, for larger and heavier pieces.

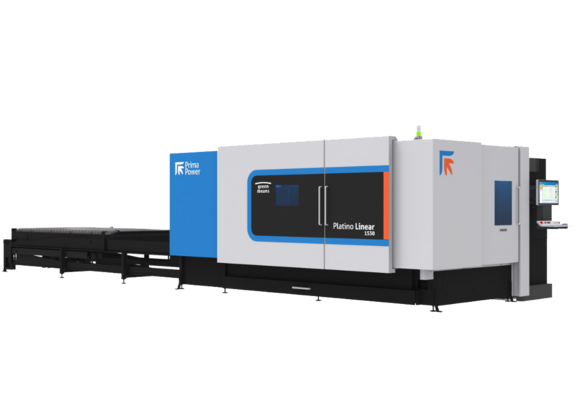

Platino Linear

2D LASER CUTTING MACHINE