Giga Laser Next

3D LASER CUTTING MACHINES

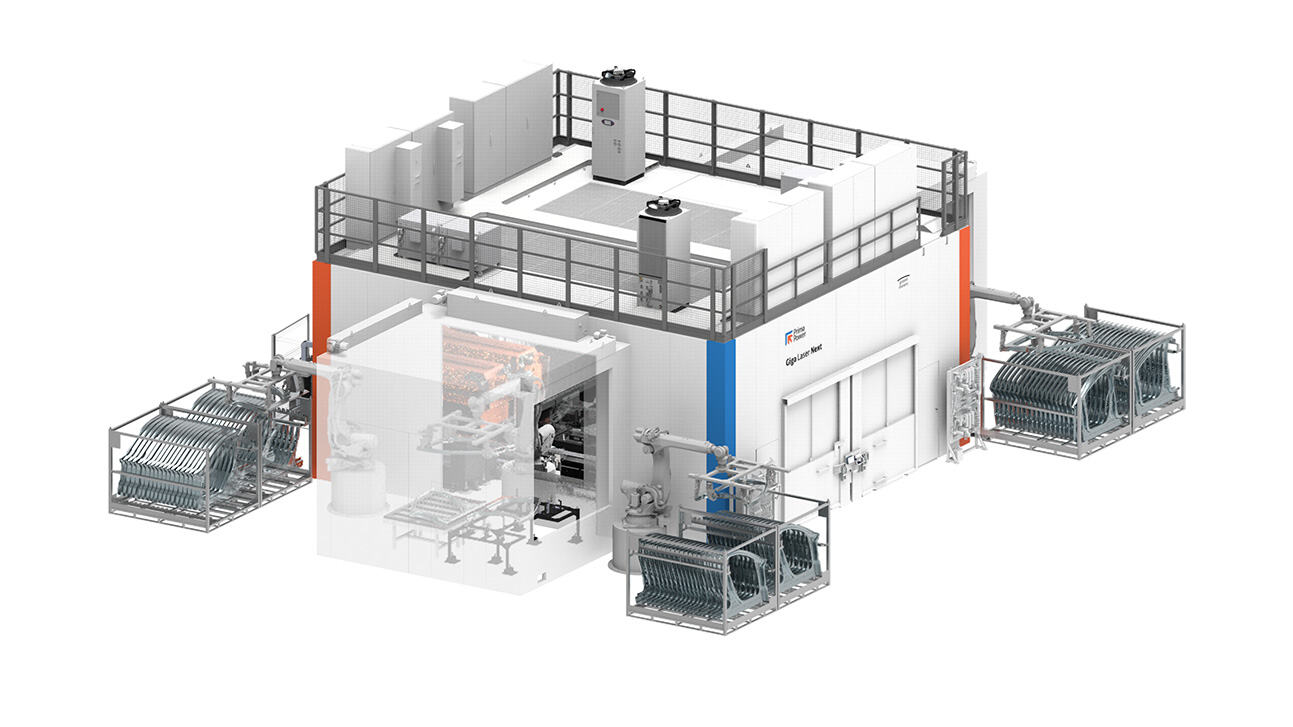

Maximum productivity and minimum floor space for automated 3D laser cutting

+280% higher productivity per m²

-75% average cutting stations required and production changeover time

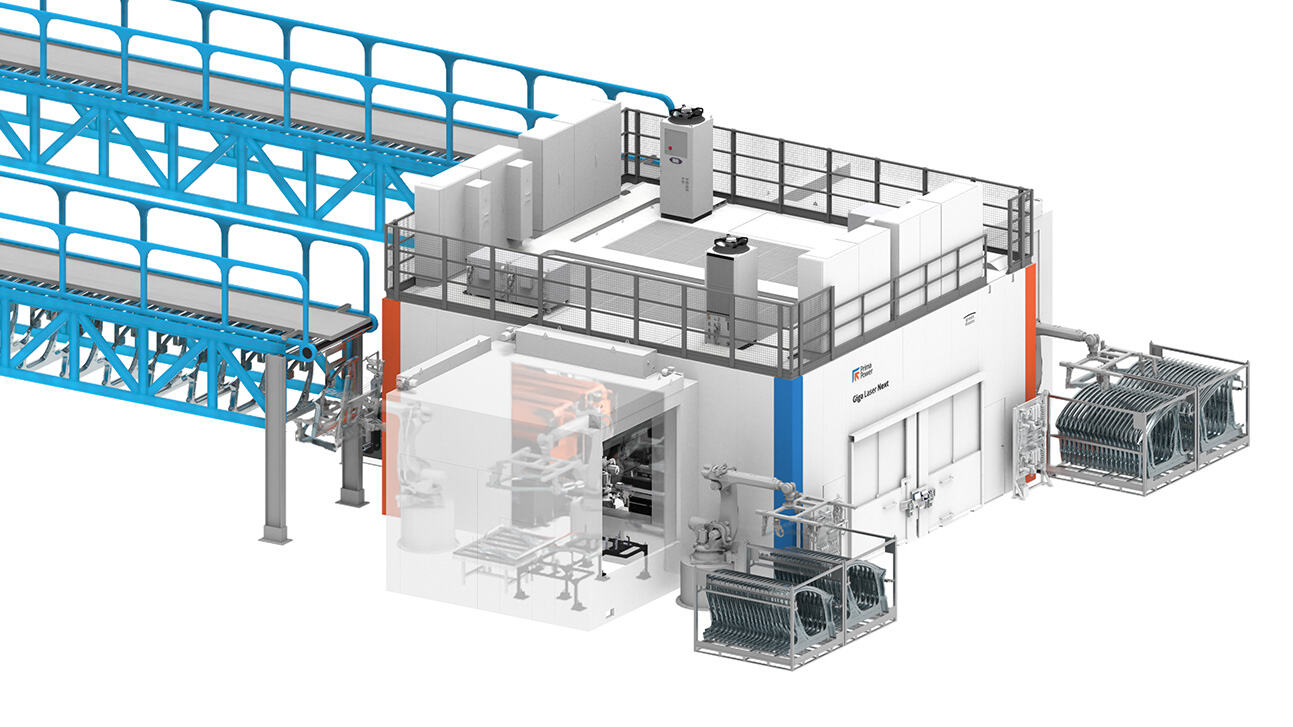

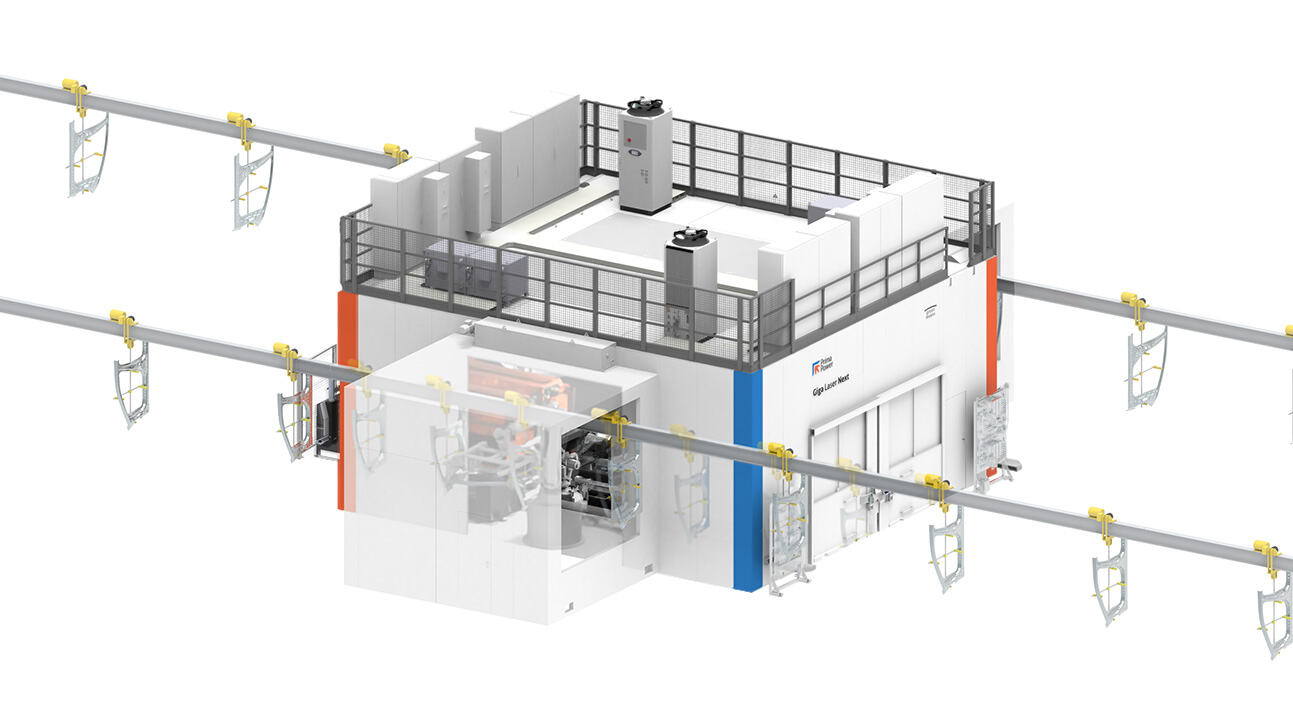

One piece flow, fully unmanned automation, complete integration into the production line

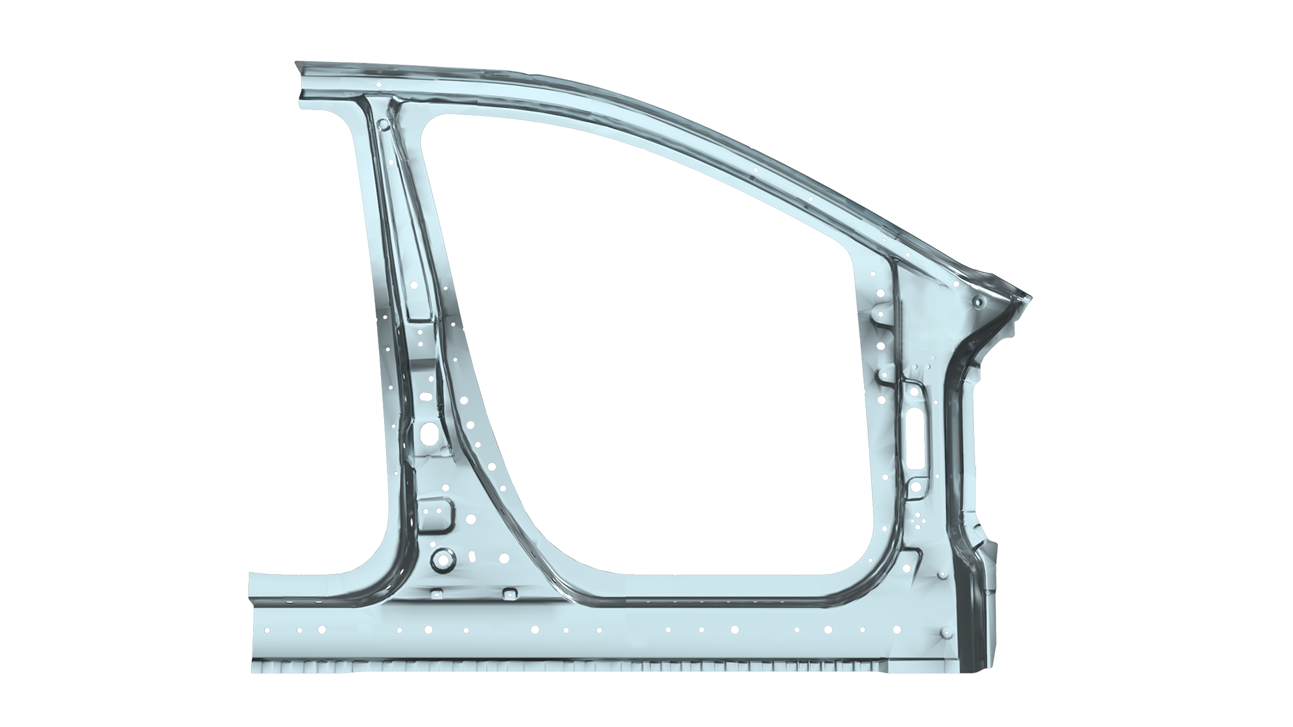

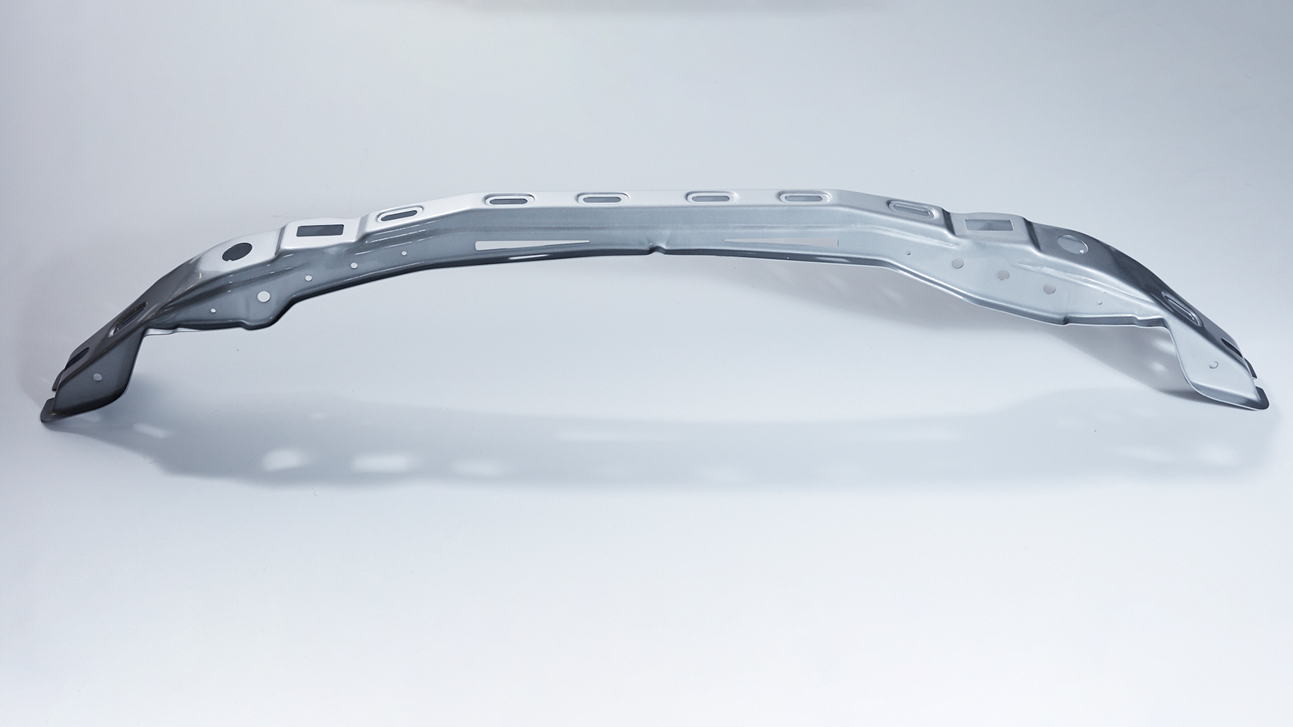

Disruptive solution for automated 3D laser process, ideal for high production volumes, such as automotive stamping and casting parts.

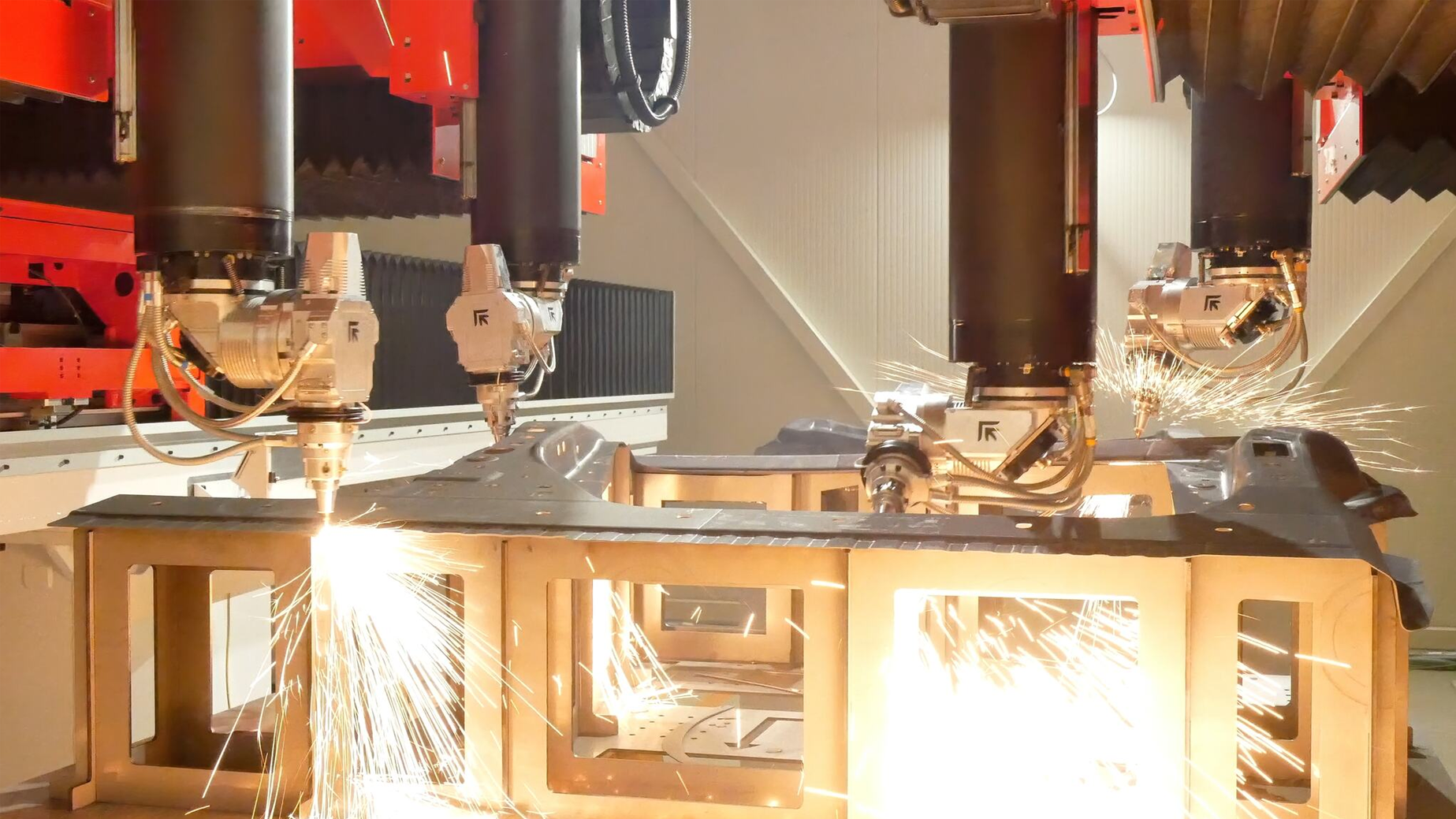

Giga Laser Next revolutionizes 3D laser cutting with four synchronized laser heads operating simultaneously on the same part. This unique multi-arms configuration enables efficiency and productivity level that previous-generation 3D laser machines could never achieve:

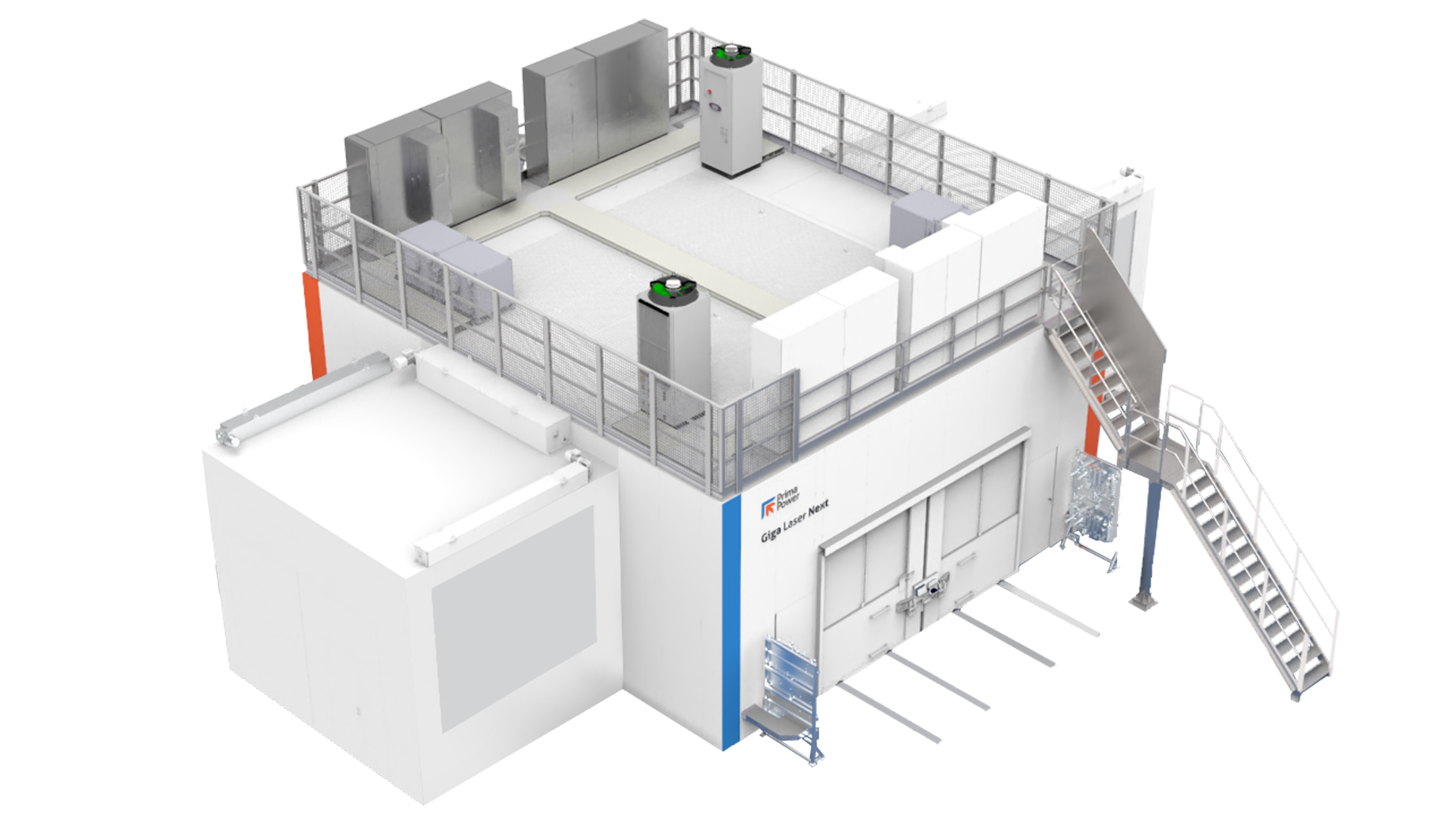

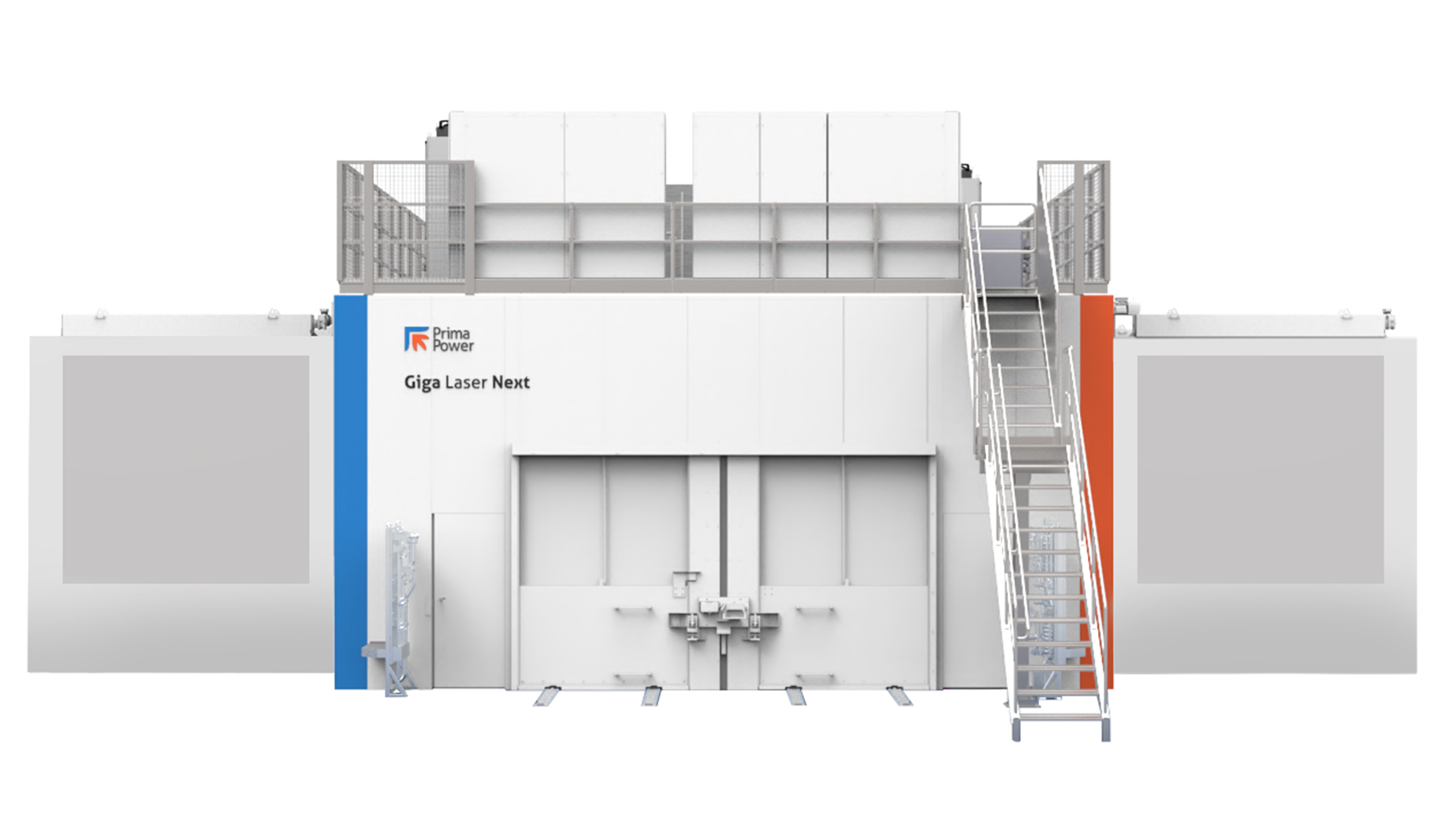

FLOOR SPACE EFFICIENCY - compact layout, with enclosure size 10 x 10 m, thanks to machine architecture, including main ancillaries (laser sources, chillers and electrical panels) located on the roof (mezzanine)

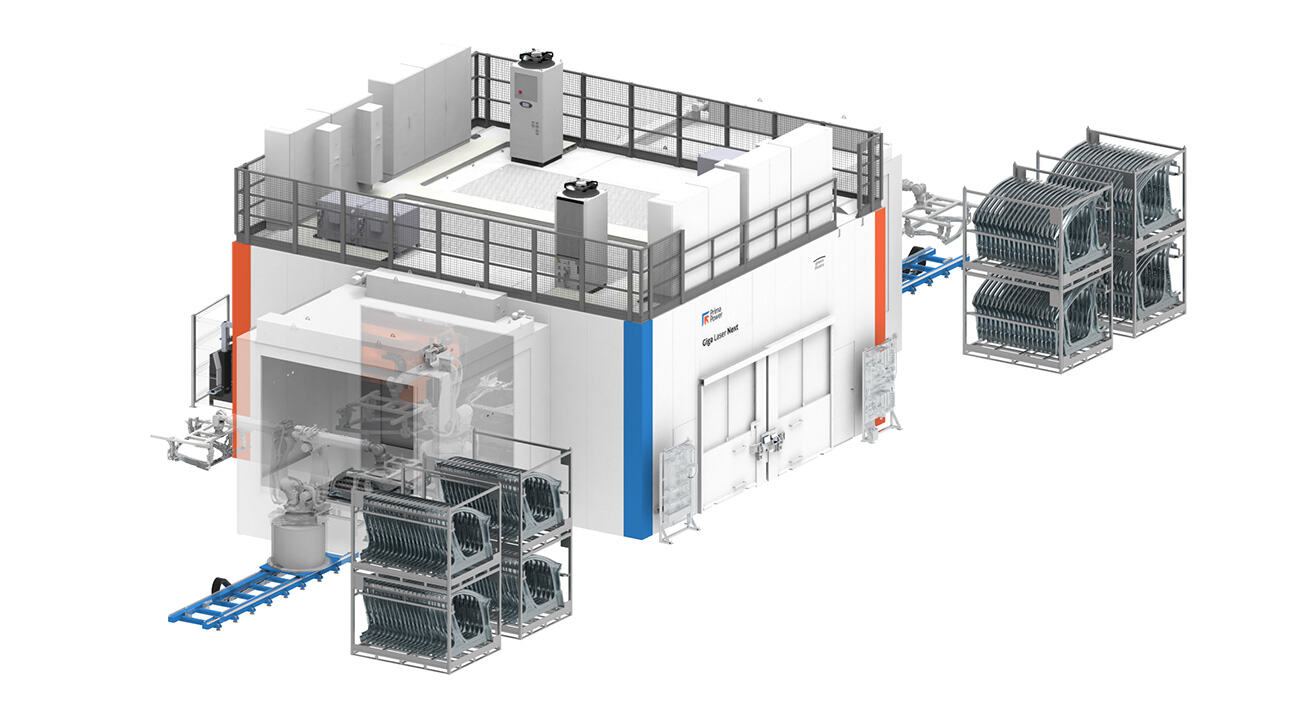

CYCLE TIME EFFICIENCY - minimum idle time with less than 2 seconds per part combined with maximum machine dynamics thanks to robust cartesian architecture and linear drives. No turn tables or other inefficient loading/systems, avoiding impacts on cycle time and machine availability.

Compared to single heads machines, the number of cutting stations is typically reduced by -75%: 1 cutting station per part on Giga Laser Next compared to typical 4 cutting stations (or even higher depending on part flows) by previous generation 3D laser machines.

The retractable arms work in overlapping areas with advanced anti-collision control, allowing the heads to operate as close as 40 mm from each other.

The machine is designed for full automation and smart integration within digital manufacturing environments. From compact layout with integrated mezzanine to seamless connection with stamping or assembly lines, Giga Laser Next optimizes both space utilization and production flow.

Engineered for long-term reliability, it combines intelligent motion, simplified maintenance, and digital twin validation to deliver maximum uptime and consistent part quality over time.

• Four synchronized laser heads cutting the same part at the same time

• Parallel operations: part loading / unloading in covered time with respect to laser processing, with typical 2 seconds of idle time

• Robust cartesian structure with high-performance Giga Cast arms, designed to guarantee the best compromise between stiffness and lightness

• Ancillaries integrated on the roof (mezzanine) to minimise the total occupied floor space

• Embedded automation for loading/unloading, quality check, marking – possible direct connection from stamping to assembly line

• Easy fixture change system, adapting the machine to different part size and shape

• Simple maintenance, thanks to machine architecture designed to minimise maintenance interventions

• Digital twin & virtual commissioning, enabling safe and fast production startup

Axis strokes

X=4,770 mm Y=2,860 mm Z=650 mm

Head axis strokes

A 360° B ±135° C ±12 mm

Speed

X, Y, Z 110 m/min (trajectory 190 m/min)

A, B 1.5 rev/s

Accuracy*

Pa, Ps 0.03 mm (VDI 3441)

Fiber laser source

3,000 W – 4,000 W

*The accuracy of the piece depends on its type, size and pre-treatment, and the conditions of application.

Prima Power 3D CAM

MACHINE PROGRAMMING

Cam application to program 3DLaser machine, provided by partner CENIT, in 3 license levels to support different use-cases

Tulus Analytics

PRODUCTION REPORTING AND MONITORING

Parts production and machine performance reporting

Related technologies

Take a look at the other products and choose the best solution

Laser Next 1530-2130

3D LASER CUTTING MACHINES

The 3D laser system for automotive production

Laser Next 2141

3D LASER CUTTING MACHINES